Process for producing purified water by adopting sewage

A pure water and technology technology, applied in the direction of heating water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of high-quality drinking water, difficult sewage treatment of chemical plants, urban water Difficulty and other problems, to achieve the effect of less land occupation, solve the shortage of urban water supply, and good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

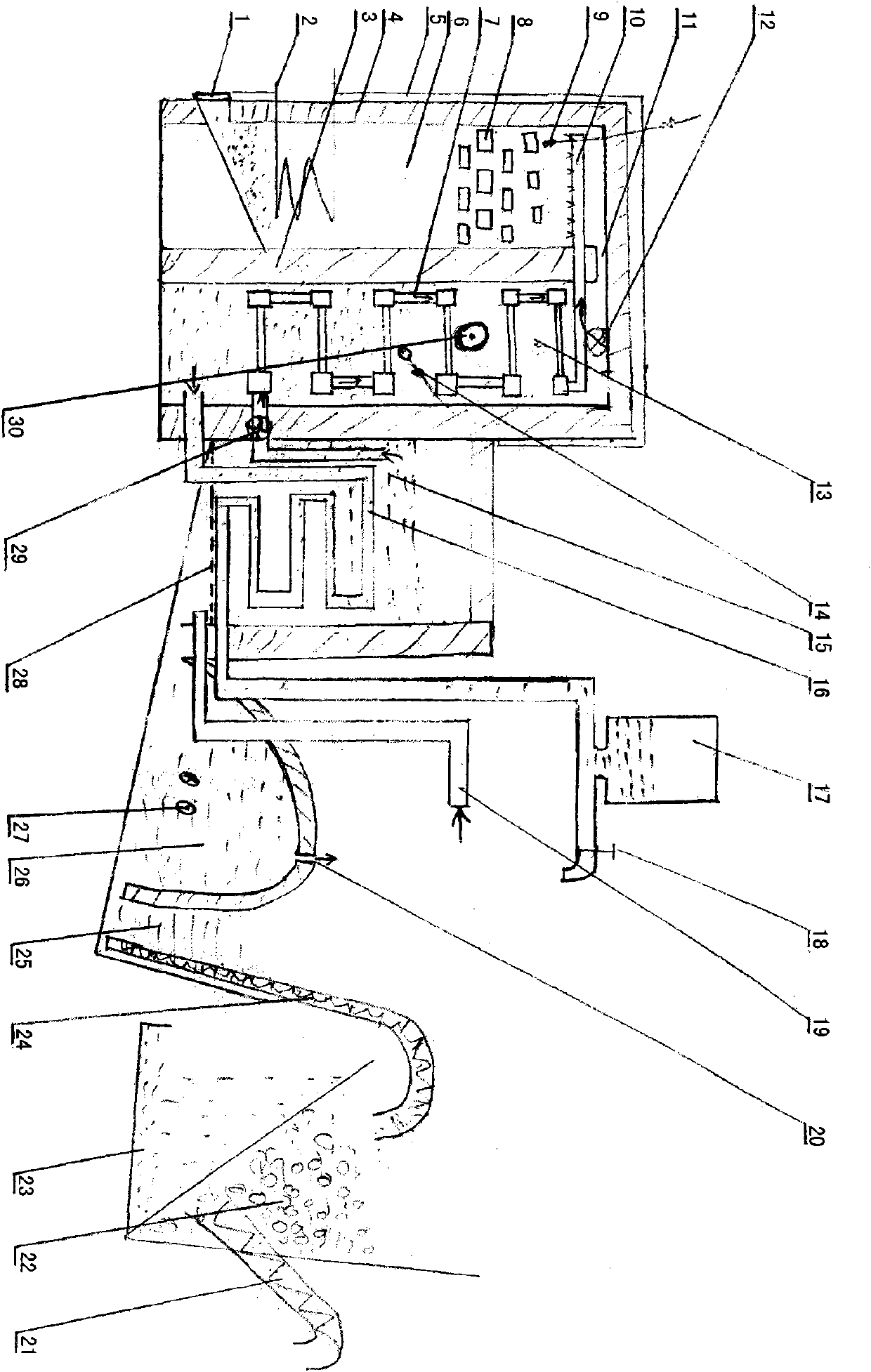

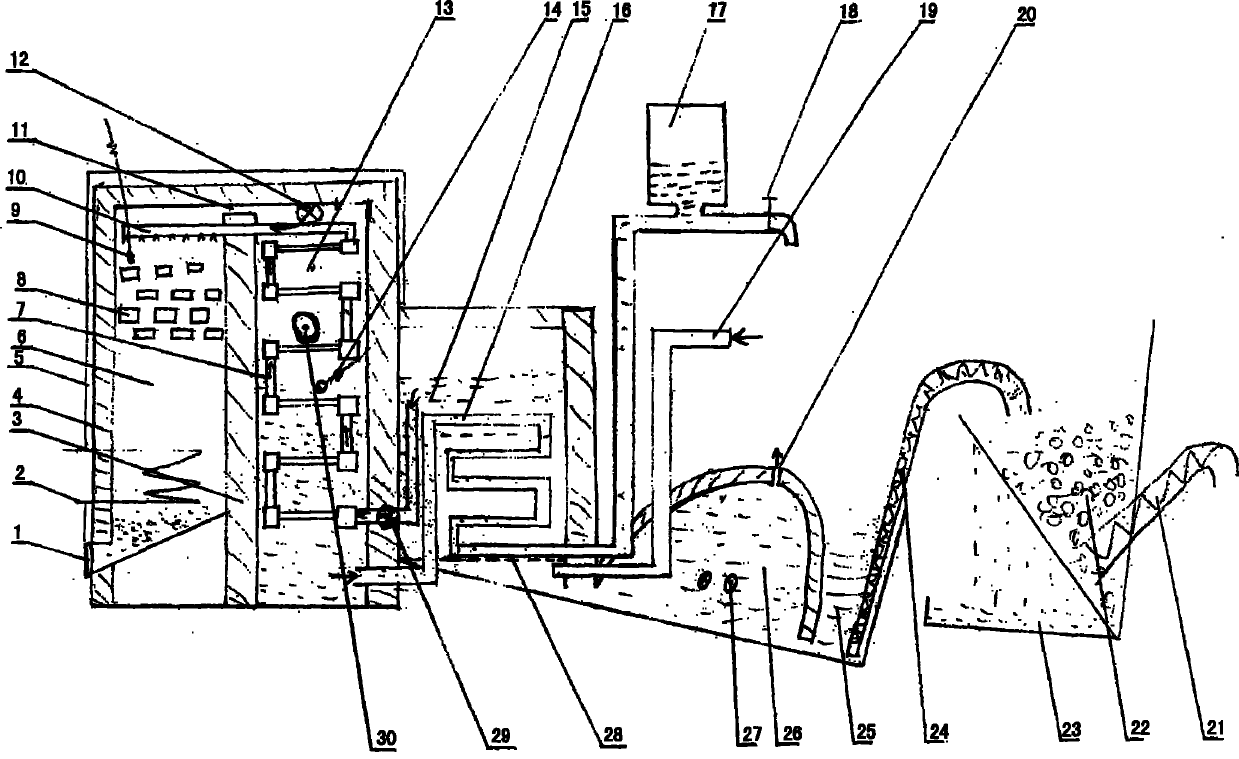

[0008] A technology for turning sewage into pure water. This article describes a treatment method for turning urban sewage into pure water in conjunction with the accompanying drawings. Chamber 6, heat exchanger 7, heat storage body 8, temperature control probe 9, shower 10, steam outlet 11, forced circulation inlet 12, liquefaction chamber 13, liquid level controller 14, liquid heat exchange pool 15, liquid Liquid exchanger 16, water purification decompression chamber 17, water purification valve 18, sewage inlet 19, biogas outlet 20, biogas residue exporter 21, sedimentation chamber 22, biogas slurry pond 23, biogas residue exporter 24, biogas residue pond 25. Biogas tank 26, biogas tank heater 27, sewage filter screen 28, self-control pump 29, forced circulation outlet 30, its operation process is that urban sewage flows into the bottom of the liquid heat exchange pool (15) through the sewage inlet (19), and passes through After the sewage filter screen (28) filters the sew...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com