Process and system for treating gasified grey water

A treatment process and treatment system technology, applied in the field of coal gasification ash water treatment process and system, can solve problems such as energy waste, environmental pollution, complicated operation, etc., achieve energy saving, avoid torch extinguishing or direct discharge, prevent overpressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

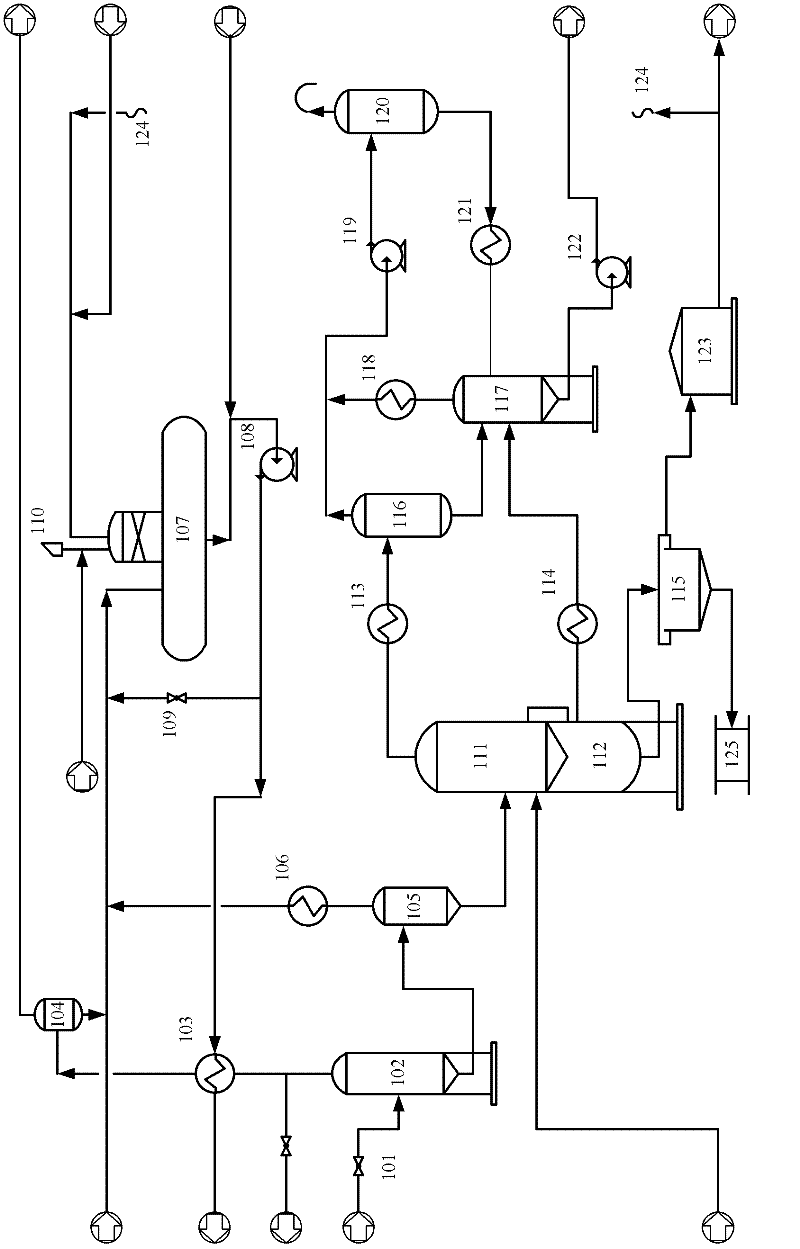

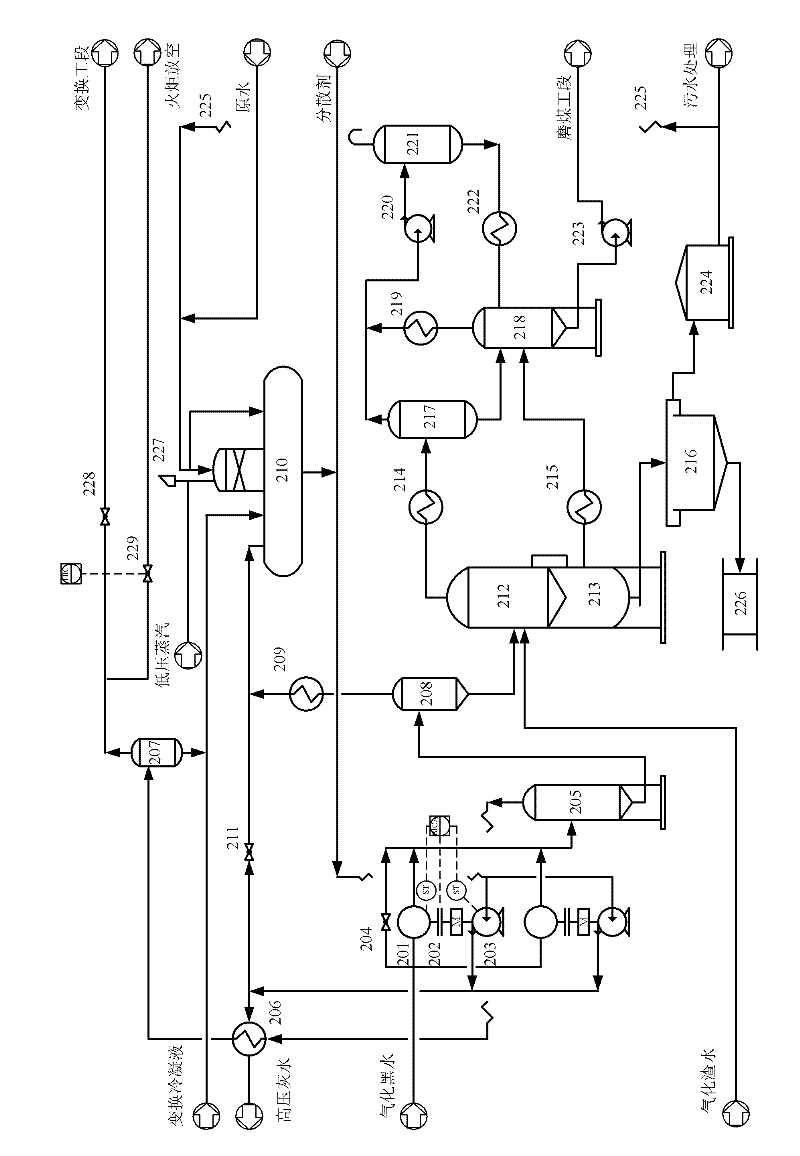

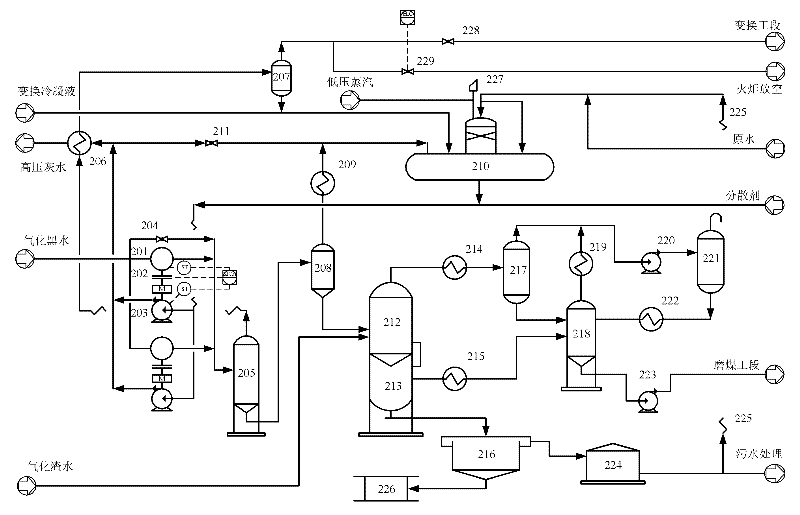

[0031] The present invention first proposes a coal gasification ash water treatment process, which specifically includes the following steps:

[0032] 1) release pressure energy

[0033] First, release the pressure energy to the gasified black water to reduce the pressure, and recover the pressure energy released by the gasified black water, and convert the released pressure energy into mechanical energy to do external work;

[0034] 2) Multi-stage flash evaporation

[0035]The gasified black water that has released the pressure energy enters the high-pressure flash tank, the low-pressure flash tank and the two-stage vacuum flash tank in turn for flash treatment, and then passes through the settling tank to remove large particles of solid impurities, and finally separates the solid impurities; The gas phase of the high-pressure flash tank enters the high-flash separator for gas-liquid separation, so that the gas phase is decomposed or the main flare is emptied, and the liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com