Fluid-solid coupling similar material for model test and preparation method for material

A model test, similar material technology, applied in the field of material science, can solve problems such as high temperature conditions, disintegration in water, not fluid-structure coupling similarity simulation, etc., to achieve the effect of solving correlation and improving similarity simulation degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1 Preparation of fluid-solid coupling similar materials used in model tests

[0036] The formula is: 320g of standard sand, 32g of barite powder, 32g of talcum powder, 20.8g of cement, 24g of vaseline, 16g of silicone oil, and 32g of mixing water.

[0037] The preparation steps are:

[0038] 1) Weigh standard sand, barite powder, talcum powder, cement, vaseline, silicone oil and mixing water in strict proportion;

[0039] 2) Mix sand, barite powder, talcum powder and cement four fine-grained materials and stir evenly;

[0040] 3) Add mixing water and stir fully;

[0041] 4) Add regulator silicone oil and mix well;

[0042] 5) Heating vaseline to 50°C to melt it into a liquid state;

[0043] 6) Mix the liquid petroleum jelly with the material and stir well;

[0044] 7) Cool at room temperature for 10 minutes to obtain.

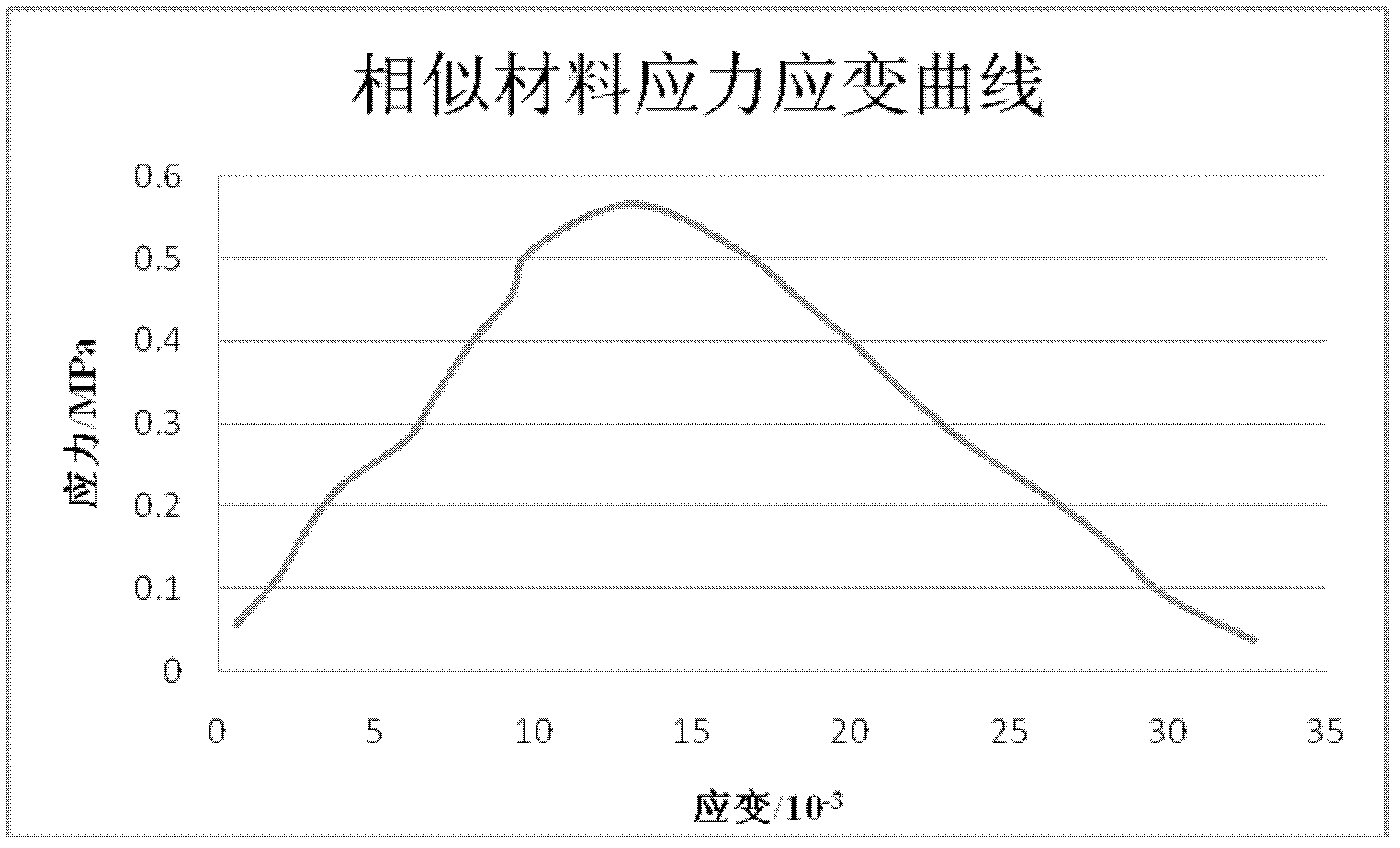

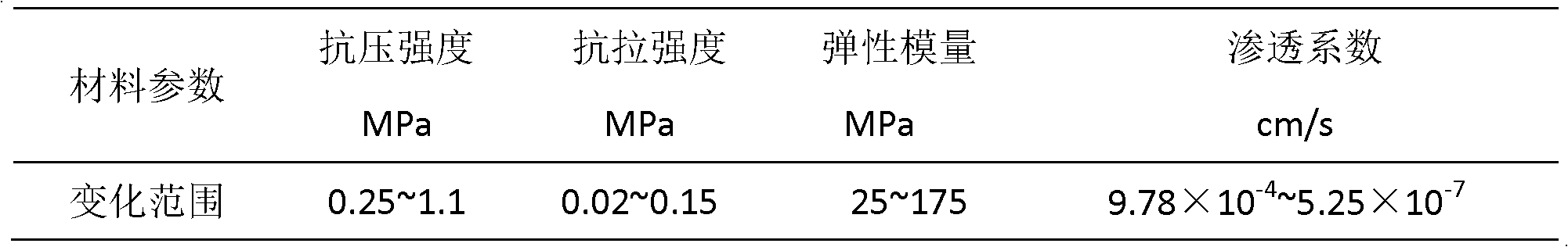

[0045] Related parameters of this ratio: weight 2.14g / cm 3 , compressive strength 0.61MPa, tensile strength 0.058MPa, elastic modulus 37M...

Embodiment 2

[0046] Example 2 Preparation of fluid-solid coupling similar materials used in model tests

[0047] The formula is: standard sand 320g, barite powder 32g, talc powder 32g, cement 20.8g, vaseline 24g, silicone oil 0, mixing water 24g.

[0048] The preparation steps are:

[0049] 1) Weigh standard sand, barite powder, talcum powder, cement, vaseline and mixing water in strict proportion;

[0050] 2) Mix sand, barite powder, talcum powder and cement four fine-grained materials and stir evenly;

[0051] 3) Add mixing water and stir fully;

[0052] 4) Heating vaseline to 50°C to melt it into a liquid state;

[0053] 5) Mix the liquid petroleum jelly with the material and stir well;

[0054] 6) Cool at room temperature for 10 minutes to obtain.

[0055] Related parameters of this ratio: weight 1.92g / cm 3 , compressive strength 0.44MPa, tensile strength 0.042MPa, elastic modulus 13MPa, permeability coefficient 8.61×10 -5 cm / s.

Embodiment 3

[0056] Example 3 Preparation of fluid-solid coupling similar materials used in model tests

[0057] The formula is: 320g of standard sand, 32g of barite powder, 32g of talcum powder, 40g of cement, 38.4g of vaseline, 12.8g of silicone oil, and 32g of mixing water.

[0058] The preparation steps are:

[0059]1) Weigh standard sand, barite powder, talcum powder, cement, vaseline, silicone oil and mixing water in strict proportion;

[0060] 2) Mix sand, barite powder, talcum powder and cement four fine-grained materials and stir evenly;

[0061] 3) Add mixing water and stir fully;

[0062] 4) Add regulator silicone oil and mix well;

[0063] 5) Heating vaseline to 50°C to melt it into a liquid state;

[0064] 6) Mix the liquid petroleum jelly with the material and stir well;

[0065] 7) Cool at room temperature for 10 minutes to obtain.

[0066] Related parameters of this ratio: weight 2.12g / cm 3 , compressive strength 0.92MPa, tensile strength 0.090MPa, elastic modulus 11...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com