Preparation method of polyurethane foam material

A technology of polyurethane foam and foam opening, which is applied in the field of polyurethane foam material preparation, can solve the problems of emulsified particle precipitation, far away from the production site, and no more than two days, so as to alleviate particle precipitation, reduce radiation factor, and low thermal conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The embodiment of the present invention discloses a preparation method of polyurethane foam, comprising:

[0035] Step a) mixing the combined polyether and cyclopentane to obtain a mixture;

[0036] Step b) mixing the mixture, foaming additive and polyisocyanate in a foaming gun, and reacting and foaming to obtain a polyurethane foam material.

[0037] The foaming additive described in the present invention preferably adopts FA-188 type foaming additive.

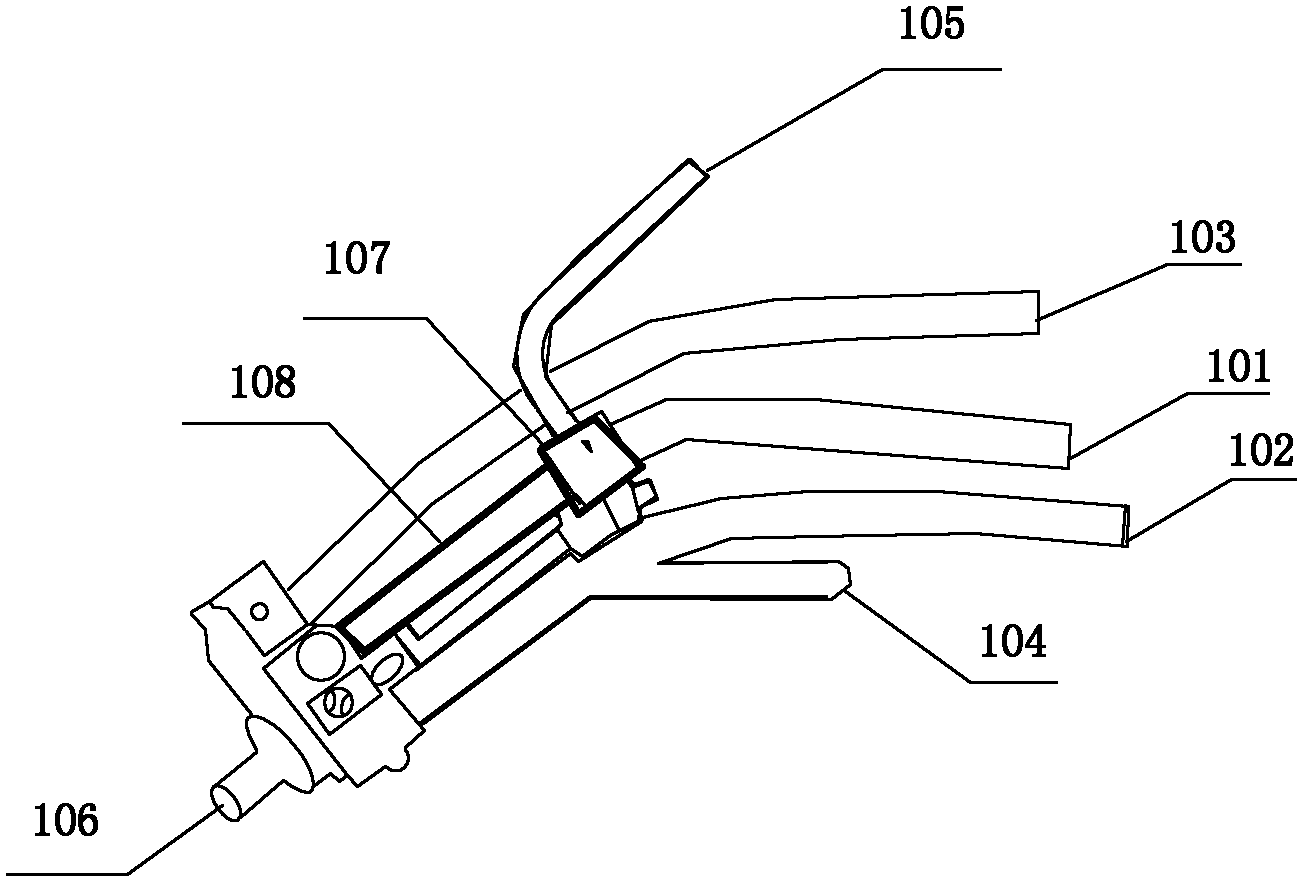

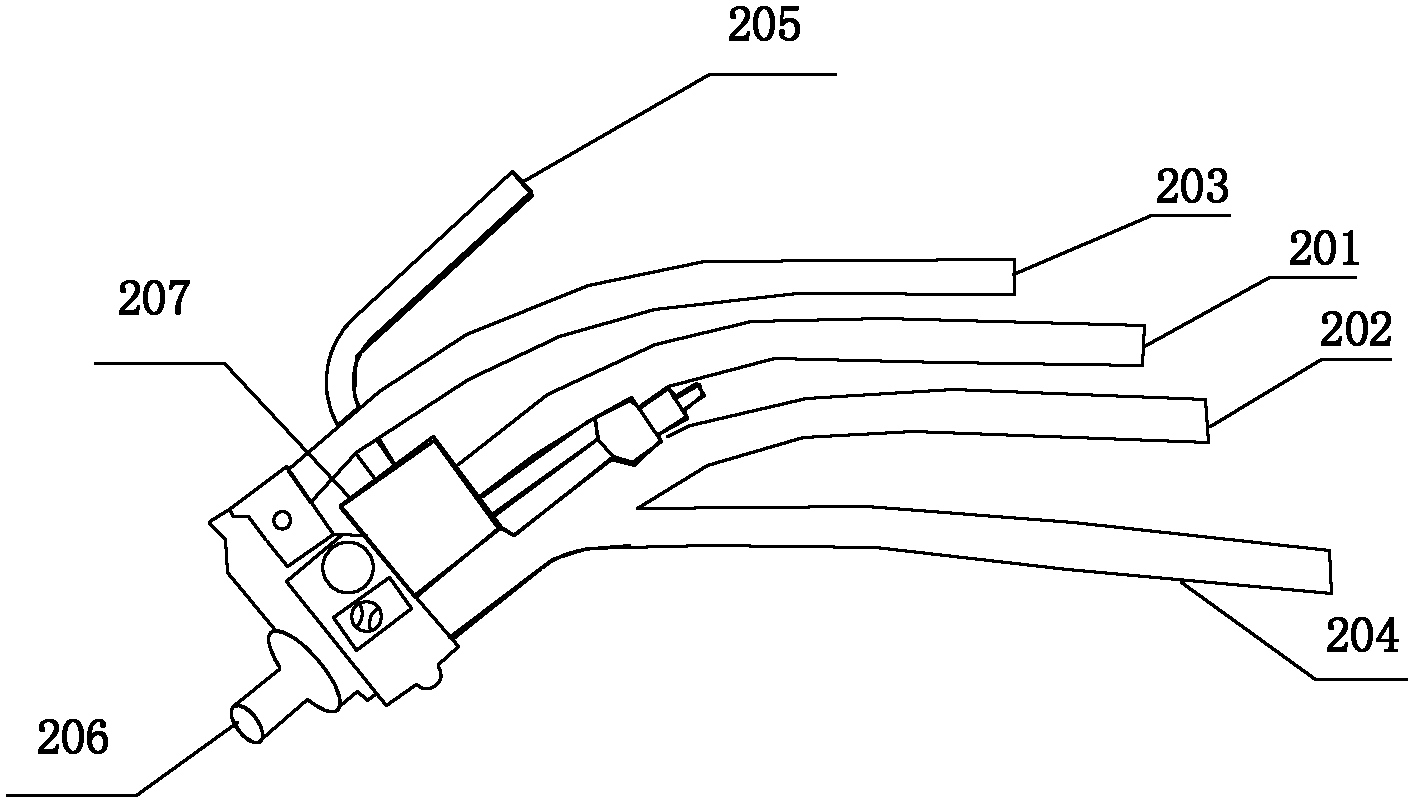

[0038] Such as figure 1 As shown, it is a schematic diagram of the preferred foaming gun used in the present invention figure 1 ,include:

[0039] Foaming port 106;

[0040] The black material inlet pipe 103 that links to each other with foaming mouth 106, is used for polyisocyanate feeding;

[0041] The injection valve 107 connected to the foaming port 106 through the static premixer 108;

[0042] The foaming additive inlet pipe 105 and the white material inlet pipe 101 that are connected with the injection val...

Embodiment 1

[0064] Step a) mixing 100 grams of combined polyether produced by Nanjing Hongbaoli Co., Ltd. and 13.5 grams of cyclopentane produced by Meilong Cyclopentane Chemical Co., Ltd. to obtain a mixture;

[0065] Step b) the FA-188 type foaming additive of described mixture, 3.8 gram 3M companies is mixed in the injection valve of foaming gun, then add and add 140 gram polyisocyanates by the black material inlet pipe of foaming gun, reaction foaming After 3 minutes, a polyurethane foam material was obtained.

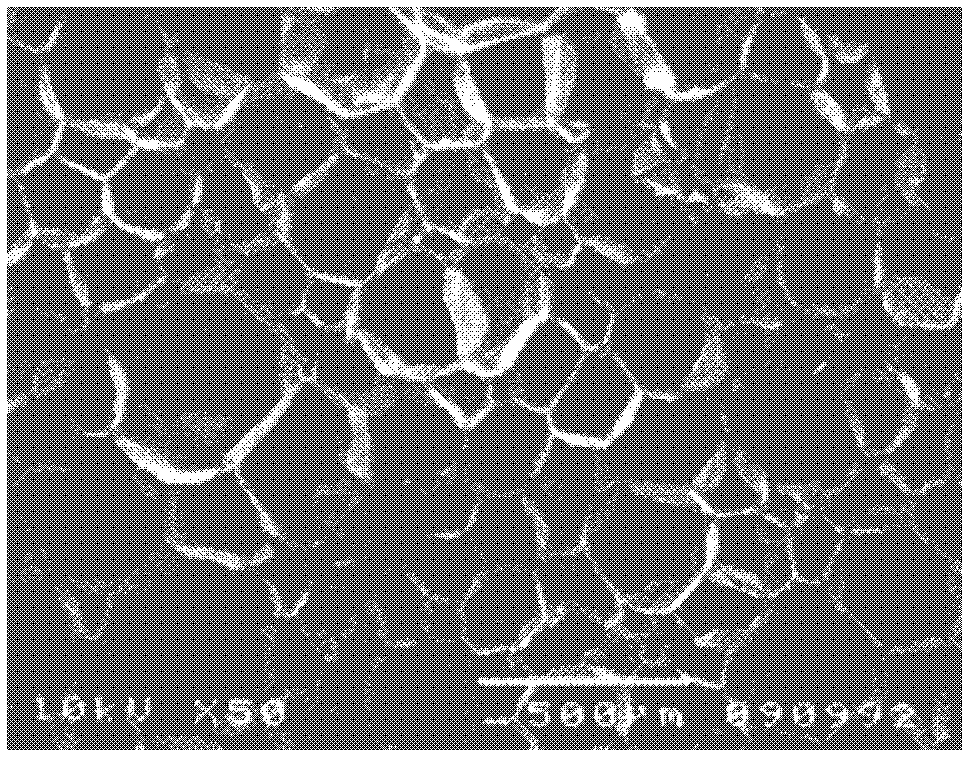

[0066] Utilize moisture tester, viscosity tester, universal testing machine, thermal conductivity meter etc. to test the polyurethane foam material prepared in this embodiment respectively, the packing density of described polyurethane foam material is 38.9kg / m 3 , heart density is 33.2kg / m 3 , the parallel compressive strength is 0.20Mpa, the vertical compressive strength is 0.16Mpa, and the thermal conductivity is 20.6mW / m·K. Such as image 3 Shown is the SEM photo of the...

Embodiment 2

[0068] Step a) mixing 100 grams of model BJ2-3879 combined polyether with 13.5 grams of cyclopentane to obtain a mixture;

[0069] Step b) mix described mixture and 3.85 grams of FA-188 type foaming additives in the static premixer of foaming gun, then add 140 grams of polyisocyanates through the black material inlet pipe of foaming gun, react and foam for 4 minutes , to obtain polyurethane foam.

[0070] Utilize moisture tester, viscosity tester, universal testing machine, thermal conductivity meter to test the polyurethane foam material prepared in this embodiment, the packing density of described polyurethane foam material is 38.9kg / m 3 , the heart density is 33.0kg / m 3 , the parallel compressive strength is 0.20Mpa, the vertical compressive strength is 0.16Mpa, and the thermal conductivity is 19.5mW / m·K.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Filling density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com