Low-impurity acarbose and preparation method thereof

An acarbose, low impurity technology, applied in the field of biochemical industry, can solve the problems of high removal cost, high impurity A, low yield, etc., and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

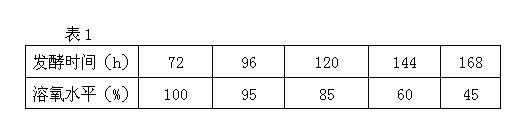

[0026] Example 1: The content of impurity A not controlled by dissolved oxygen level

[0027] 10-ton tank, the filling coefficient is controlled at 0.8, and the air flow rate is 8.0m 3 / min (1.0vvm), the speed is controlled at 120 r / min until the end.

[0028] Real-time monitoring of the changes of A impurities with fermentation time and dissolved oxygen level in the fermentation process is shown in Table 3:

[0029]

Embodiment 2

[0031] 10-ton tank, start fermentation at about 72 hours, gradually increase the stirring speed, and the stirring speed will reach 150 r / min within 24 hours, and monitor in real time to keep the dissolved oxygen level at about 100%; start at about 120 hours, maintain the previous Stirring speed of the same, while increasing the air flow to 12.0m 3 / min (1.5vvm), real-time monitoring, keep the dissolved oxygen level at about 100%; in about 144 hours, under the condition of maintaining the stirring speed and air flow, add 400L of sugar water (accounting for about 5% of the total volume of the fermentation broth), The culture medium in the fermenter is diluted and monitored in real time to keep the dissolved oxygen level above 90%.

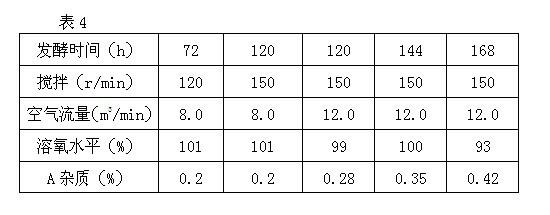

[0032] The real-time measured content of impurity A is shown in Table 4:

[0033]

Embodiment 3

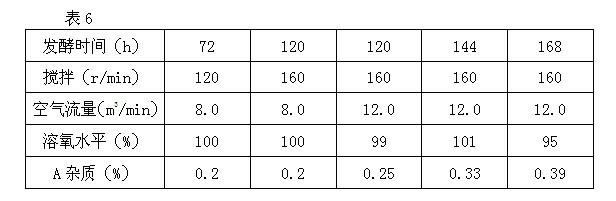

[0035] 60 tons of tanks, fermentation starts at about 72 hours, and the air flow increases to 12.0m 3 / min (1.5vvm), real-time monitoring, to keep the dissolved oxygen level above 95%; starting at about 120 hours, keep the previous air flow unchanged, and gradually increase the stirring speed to 150 r / min to keep the dissolved oxygen level at More than 90%, in about 144 hours, under the condition of maintaining the constant air flow and stirring speed, add 400L of sugar water (accounting for about 5% of the total volume of the fermentation broth), dilute the medium in the fermenter, monitor in real time, and keep The dissolved oxygen level is above 80%.

[0036] The real-time measured content of impurity A is shown in Table 5:

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com