Annealing method for hollow rolled object

A roll-shaped, hollow technology, applied in furnaces, heat treatment equipment, heat treatment furnaces, etc., can solve the problems of poor annealing effect, large energy waste, and long annealing time of the annealing furnace for hollow rolls, and shorten the annealing time and temperature. Uniformity, the effect of improving heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

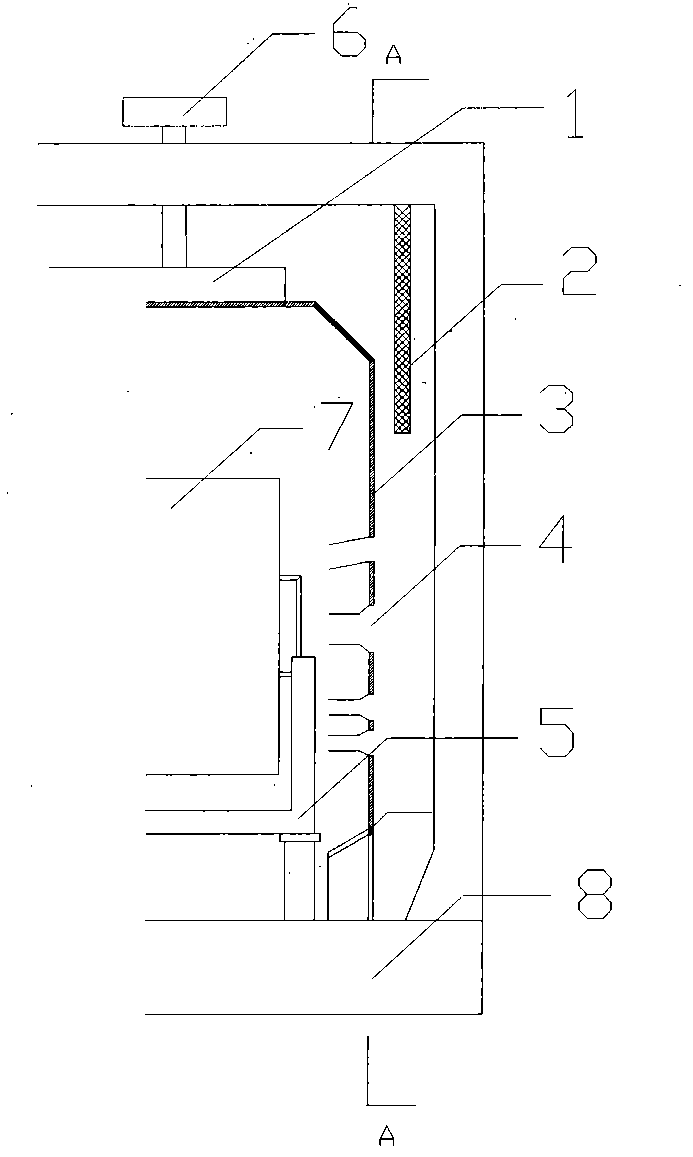

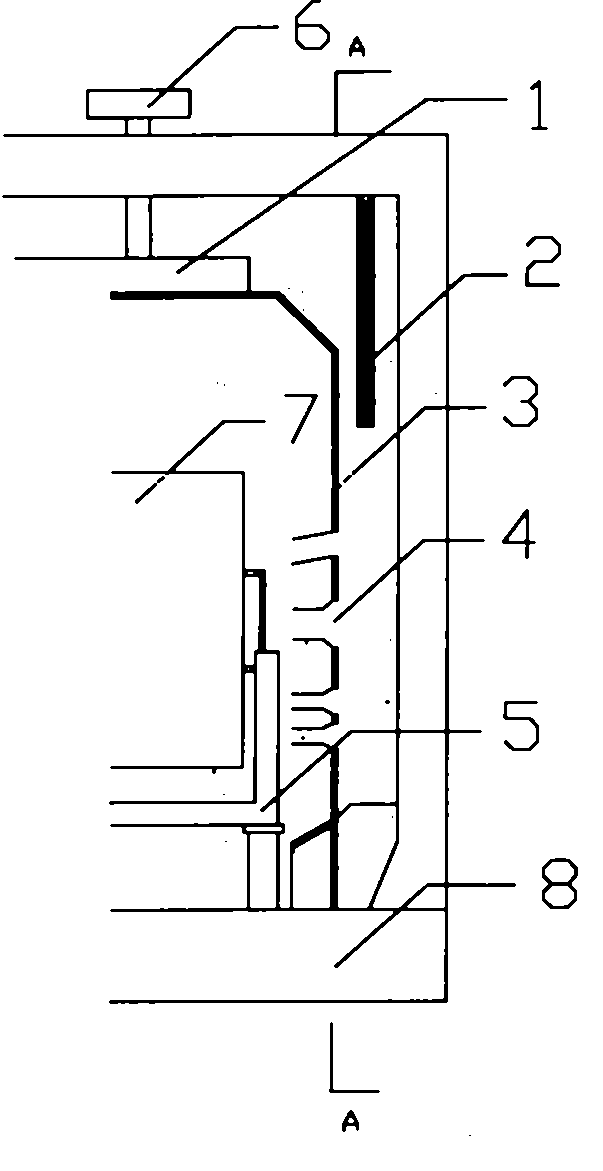

[0024] Embodiment one, see figure 1 and figure 2

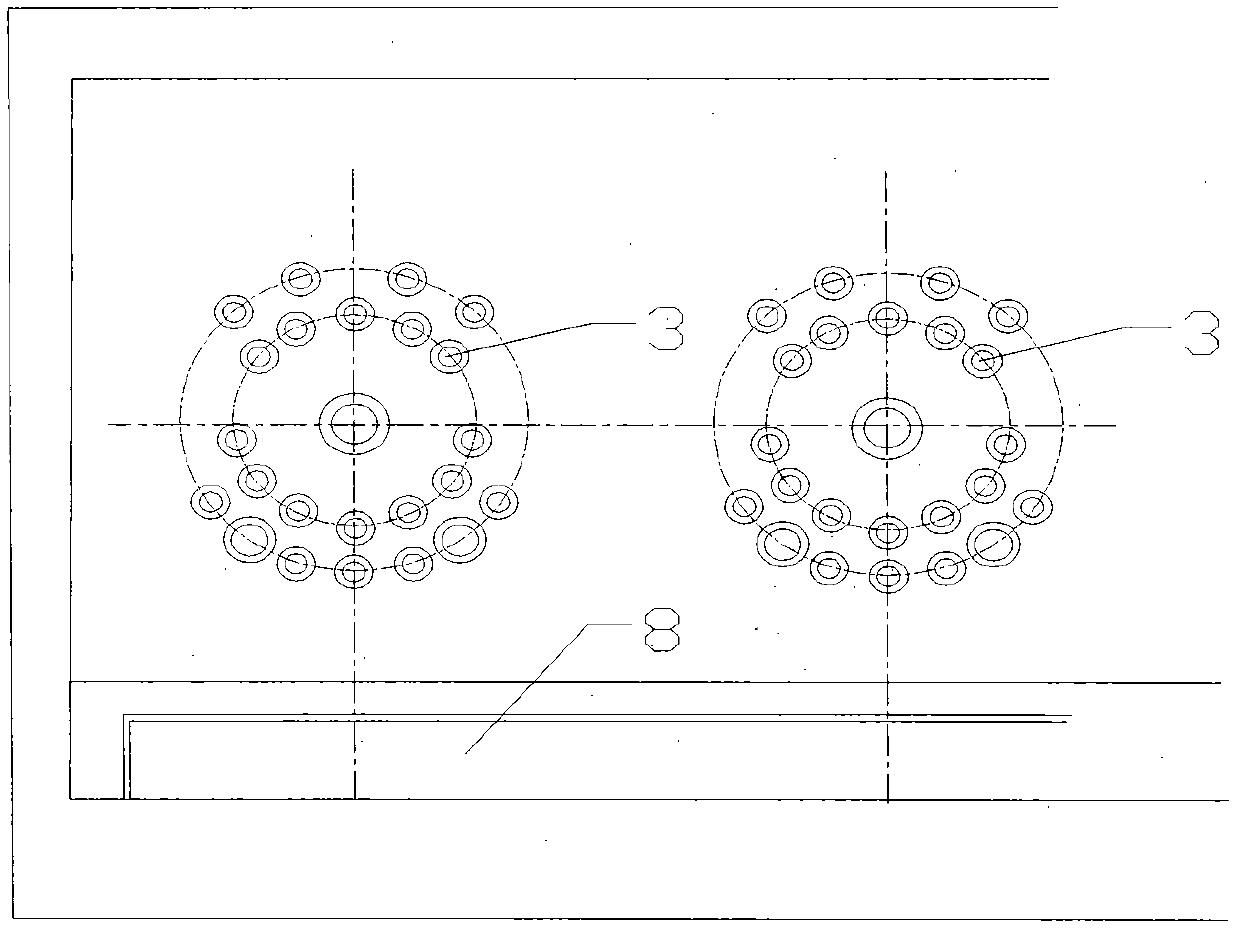

[0025] Step 101: Place the hollow roll 7 horizontally on one side of the deflector 3, and the deflector 3 is provided with at least two nozzles 4 with different diameters; the nozzles 4 are arranged as at least two concentric circles array.

[0026] A hollow roll support member 5 is provided on one side of the deflector 3 , and the hollow roll 7 is horizontally placed on the hollow roll support member 5 with its roller axis parallel to the ground.

[0027] The caliber of the nozzle 4 is different, and the high-temperature airflow can be purposefully and targetedly introduced into the weak points of the traditional heating method, such as the core of the hollow roll, the upper side of the hollow roll, etc., thereby accelerating the hollowing process. The time for each part of the roll to reach the temperature of the oven. Therefore, nozzles 4 with larger diameters can be arranged on the deflector 3 at positions correspondi...

Embodiment 2

[0033] Step 201: Place the first hollow roll 7 horizontally on one side of the deflector 3, the height of the centerline of the roller shaft of the first hollow roll is the same as the height of the nozzle at the center of the first concentric circle array unanimous.

[0034] Step 202: Place the second hollow roll 7 laterally on one side of the deflector 3, the height of the centerline of the roller axis of the second hollow roll is the same as the height of the nozzle at the center of the second concentric circle array unanimous.

[0035] If there is also a third concentric circle array and a fourth concentric circle array on the deflector 3, the third hollow roll and the fourth hollow roll can also be horizontally placed on the guide plate according to steps 201 and 202. Flow plate 3 side.

[0036] The height of the nozzle located at the center of the concentric circle array is the same as the height of the centerline of the hollow roll roller, so that the nozzle located a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com