Automatic circulation plasma vapor phase deposition system

A technology of plasma gas and automatic circulation, applied in the field of ion vapor deposition system, to achieve the effect of stable valve core structure, wide application range and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

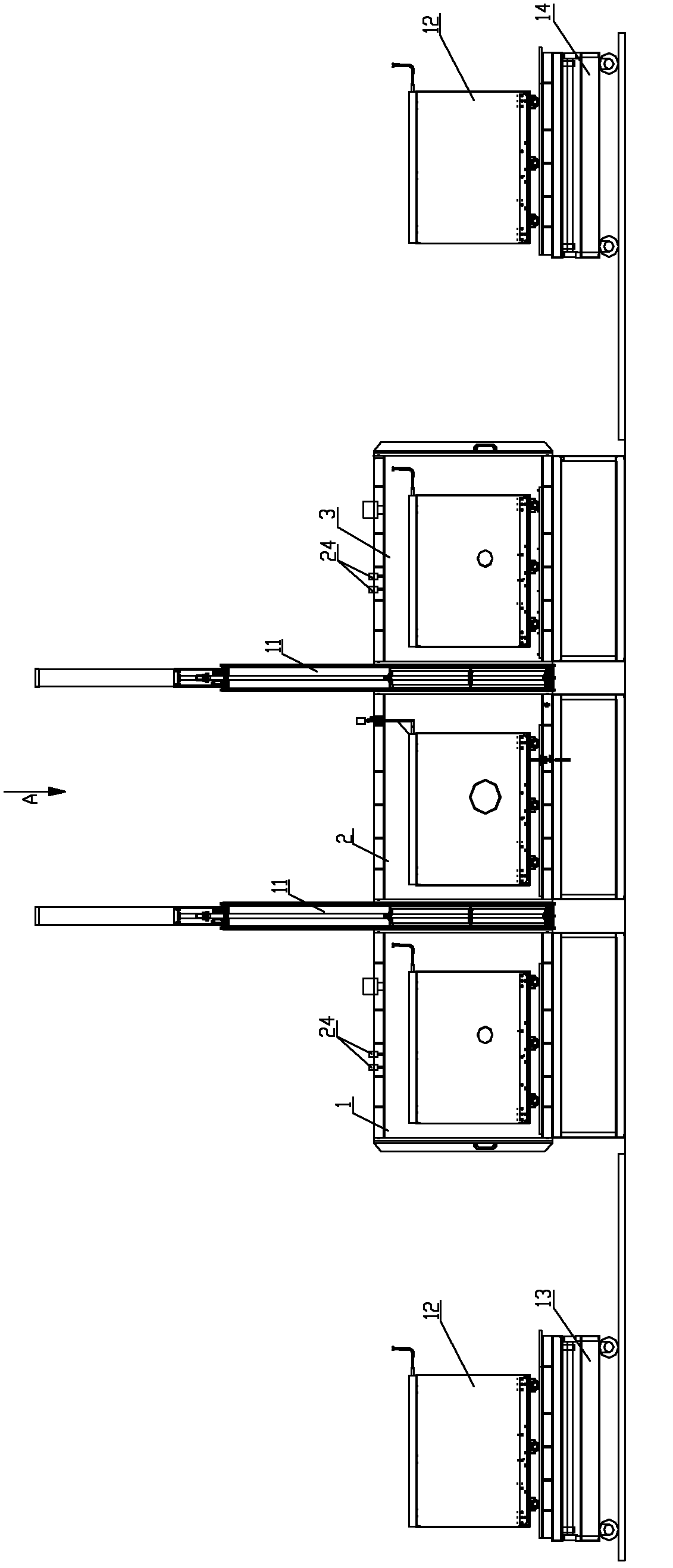

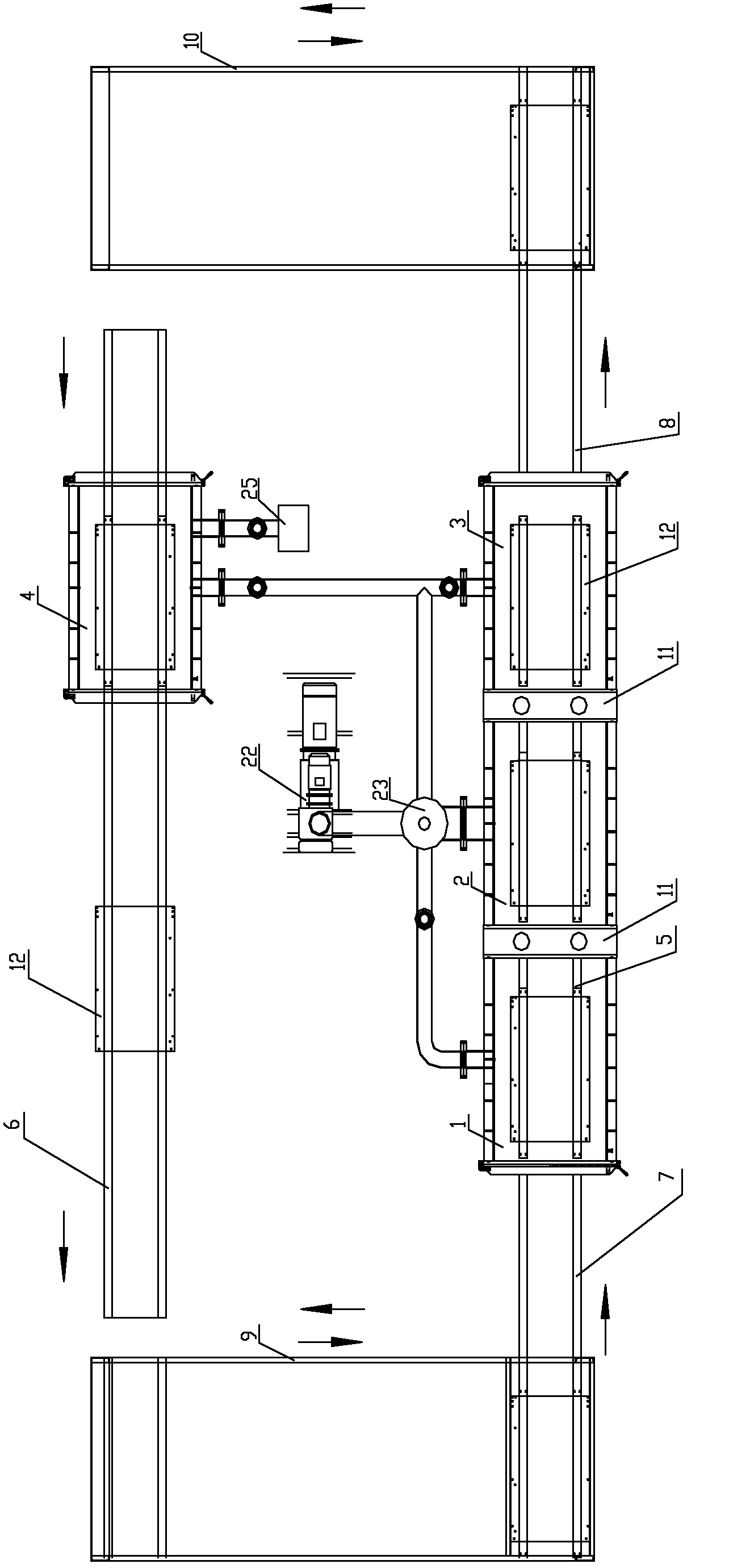

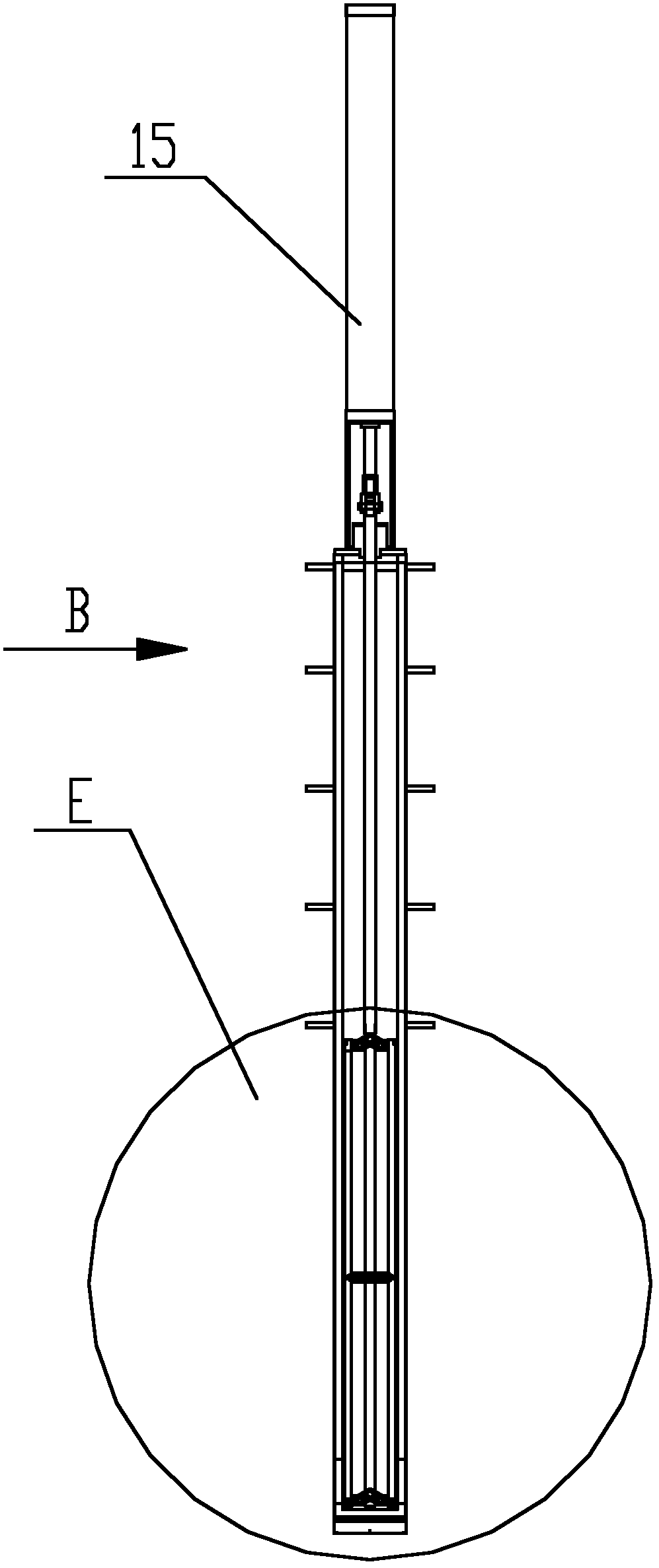

[0031] This embodiment is an automatic circulation plasma vapor deposition system, its structure is as follows figure 1 or figure 2 As shown, it includes a preheating chamber 1, a plasma vapor deposition chamber 2, a cooling chamber 3 and a cleaning chamber 4, the preheating chamber, the plasma vapor deposition chamber and the cooling chamber are sequentially connected by the first guide rail 5, and the cleaning chamber and the cooling chamber are arranged in parallel, The bottom of the cleaning room is provided with a second guide rail 6, and the two ends of the first guide rail are respectively provided with an entry guide rail 7 and an exit guide rail 8. 10 are connected and arranged perpendicular to each other, the first guide rail, the second guide rail, the first conveyor belt and the second conveyor belt form a rectangular structure; the preheating chamber, the plasma vapor deposition chamber, the cooling chamber and the cleaning chamber are respectively connected with...

Embodiment 2

[0041] This embodiment is an automatic circulation plasma vapor deposition system, its specific structure is as follows Figure 8 or Figure 9 As shown, compared with embodiment 1, its difference is that plasma vapor deposition chamber 2 has 6, and 6 plasma vapor deposition chambers are arranged in series between preheating chamber and cooling chamber, and each plasma vapor deposition chamber is connected with respectively The vacuum mechanism is connected, and a vacuum lock is arranged between two adjacent plasma vapor deposition chambers. For glass workpieces that require multi-layer deposition, multiple plasma vapor deposition chambers are provided, and each plasma vapor deposition chamber can be filled with different gases according to the process requirements, compared to alternately filling different gases in the same plasma vapor deposition chamber In this case, cross-contamination of different gases can be avoided.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com