Negative-pressure dustless moxa extracting equipment and production process thereof

An extraction equipment and moxa velvet technology, which is applied in the field of negative pressure dust-free moxa velvet extraction equipment and its production process, can solve the problems of inability to meet large-scale production, harsh working environment, complex process, etc., and achieve easy automatic control, Improve the working environment and the effect of uniform texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

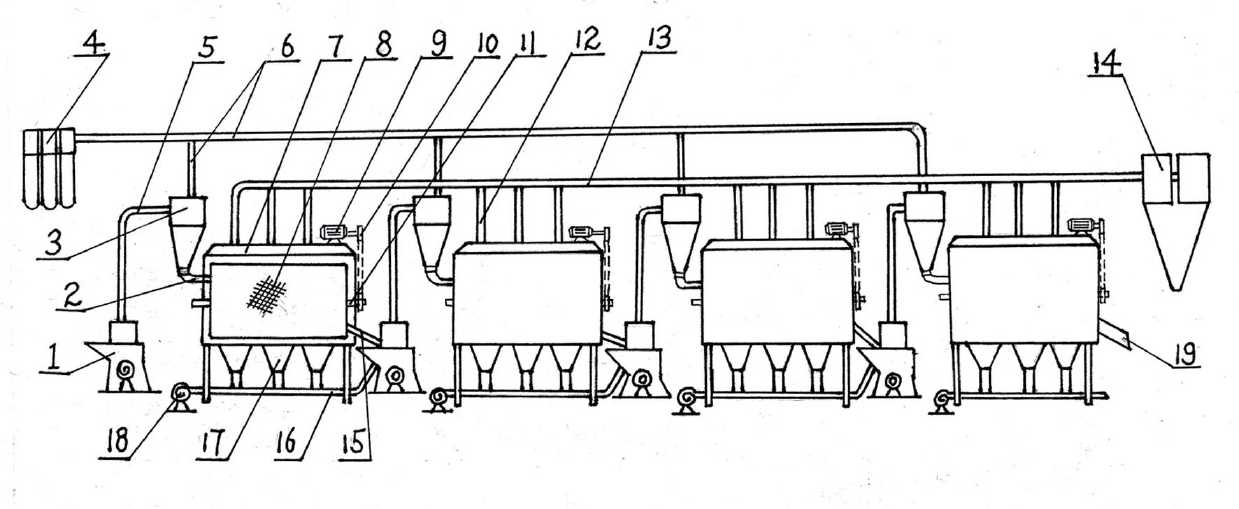

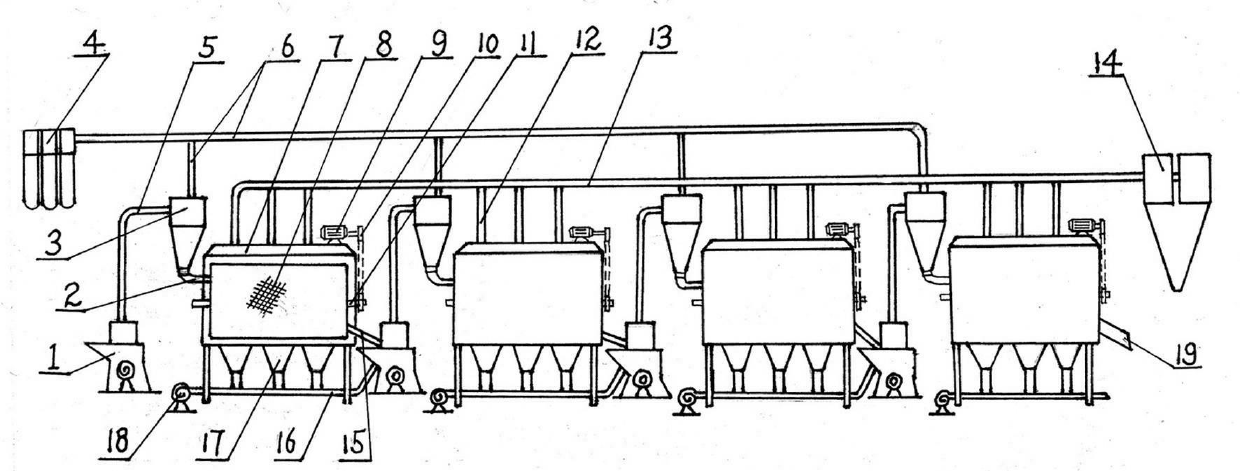

[0021] see figure 1 , the negative pressure dust-free type moxa extracting equipment of the present invention comprises fine velvet collector 14, deduster 4 and four cover sequentially connected moxa extracting devices, and described moxa extracting device is composed of grinding pulverizer 1, separator 3 It is composed of a delinting machine, wherein the feed port of the grinder 1 is provided with a dustproof shield, and a fan is arranged inside it, and a feeding pipeline 5 is connected to one side of the grinding grinder, and the other side of the feeding pipeline 5 One end is connected and communicated with the separator 3 and the cashmere remover, and the pulverized raw materials can be sent to the separator 3 by means of the wind pressure generated in the grinder 1 . The fleece remover is connected with the fine fleece collector 14 through the negative pressure fleece suction pipe 12 and the fine fleece conveying pipeline 13, and the fine moxa is sucked out from the fleec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com