Method for constructing non-filled vibration-compacted sand piles on silty-fine sand foundation

A construction method, the technology of silt and fine sand, applied in the direction of infrastructure engineering, soil protection, construction, etc., can solve the problems of poor foundation reinforcement treatment effect, unsuitable for deep foundation reinforcement, complicated construction technology, etc., achieve less equipment configuration, The pile quality is easy to control and the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

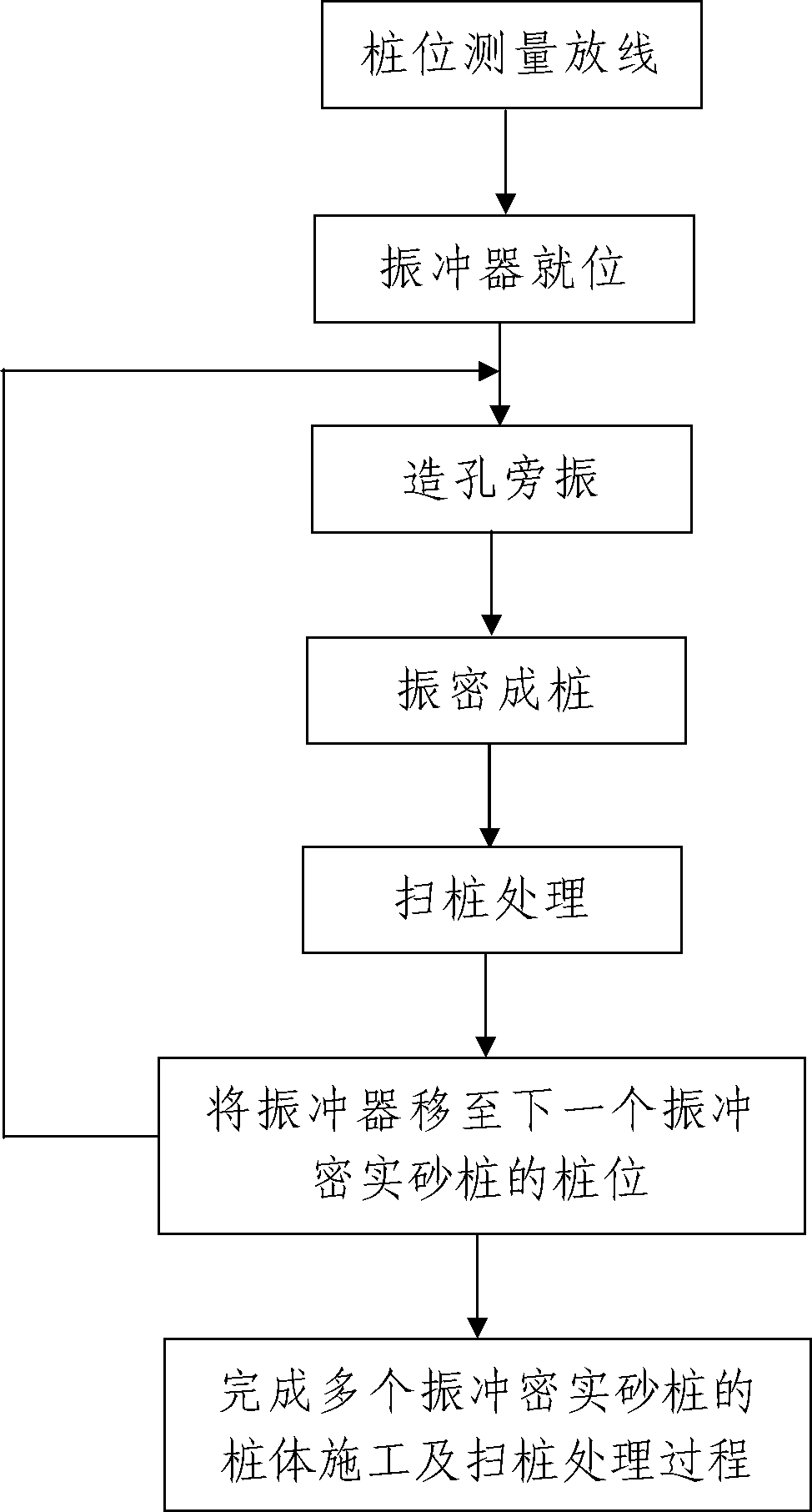

[0045] Such as figure 1 A construction method for vibro-compacting sand piles without filling in the silt fine sand foundation shown comprises the following steps:

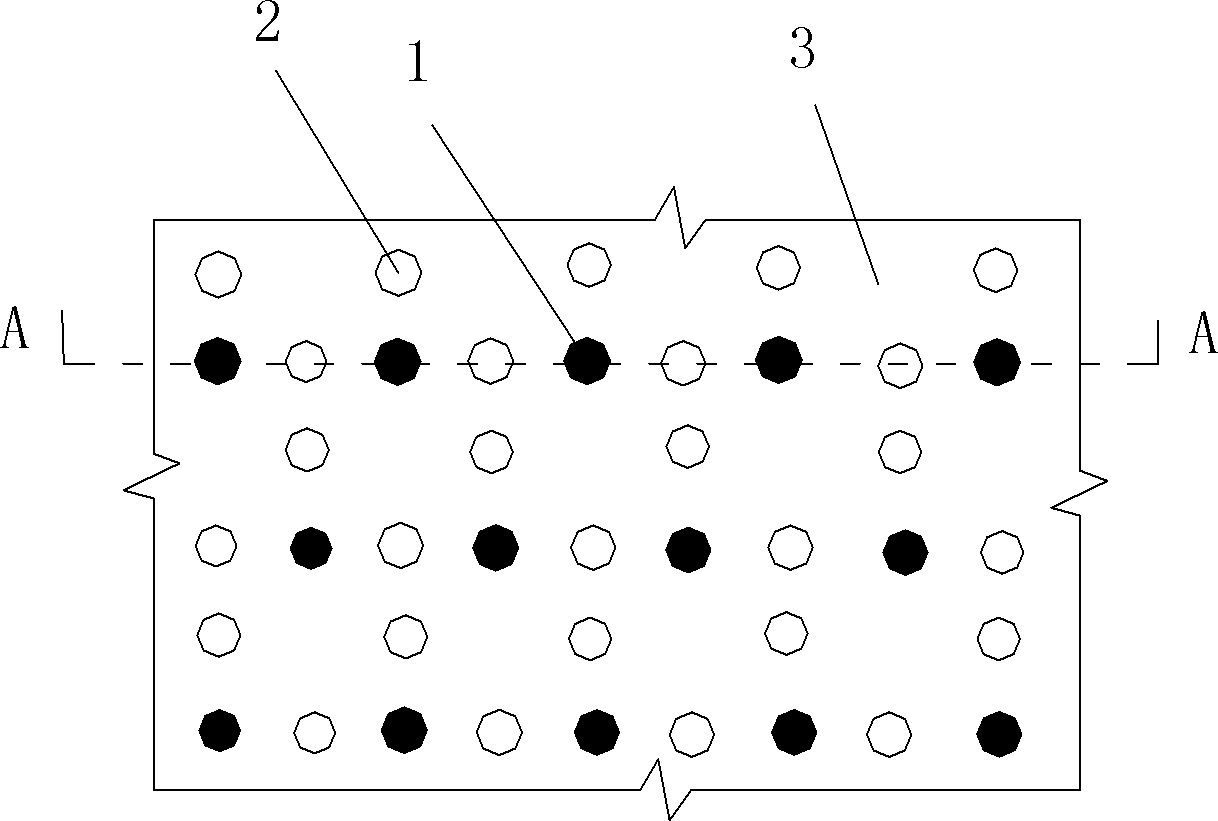

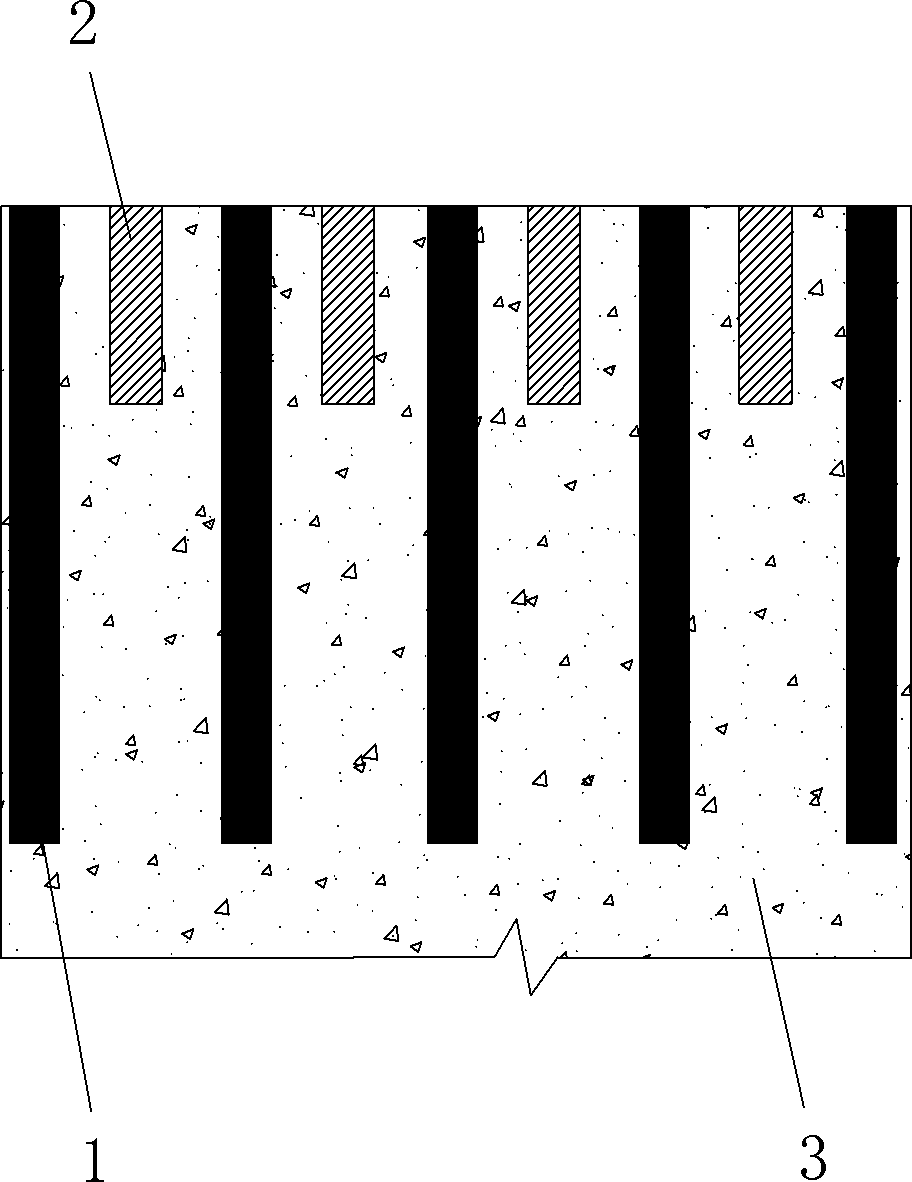

[0046] Step 1. Pile position measurement and setting out: according to the conventional pile position measuring and setting out method, the pile positions of multiple vibro-consolidated sand piles 1 to be constructed are measured and set out respectively on the silt fine sand foundation 3 to be constructed. See figure 2 and image 3 ;

[0047] A plurality of the vibro-compacted sand piles 1 are arranged in an equilateral triangle, and the distance between two adjacent vibro-compacted sand piles 1 is 1.4m to 1.6m, and the vibro-compacted sand piles 1 The pile length shall not exceed 12m. The pile diameter of the vibrating compacted sand pile 1 is 0.9m±0.2m.

[0048] Therefore, during the actual pile layout, the pile holes of the plurality of vibro-compacted sand piles 1 are arranged in an equilateral triangle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com