Wall brushing method for underground continuous wall

An underground continuous wall and wall brushing technology, applied in the field of construction engineering, can solve the problems of increasing the dead weight of the box, reducing the wall brushing efficiency, affecting the wall brushing effect, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

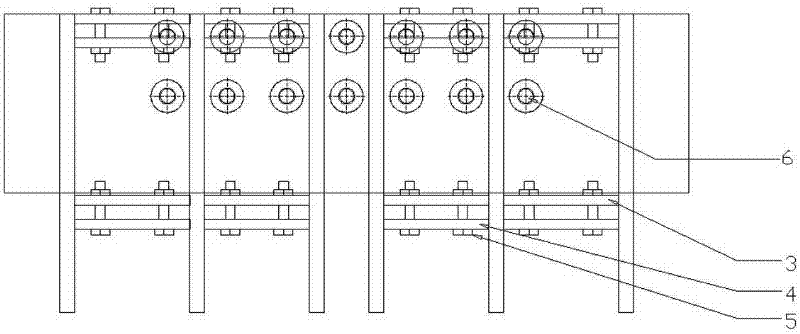

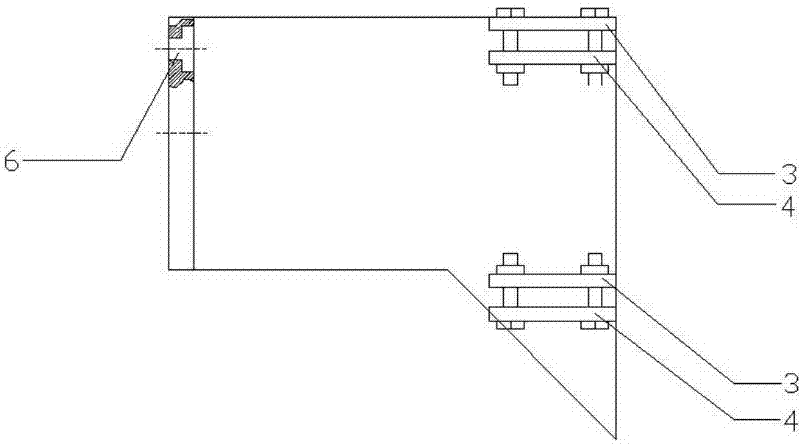

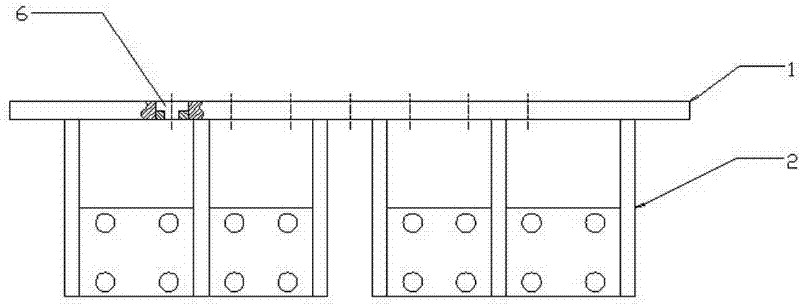

[0023] Embodiment one: if Figure 1~3 As shown, the connecting plate 1 is welded with six shovel plates 2 in the vertical direction, and the shovel plates 2 are in the shape of inverted bucket teeth. The shoveling plates 2 are distributed on the connecting plate 1 at certain intervals. At the gap between the shovel plates 2, that is, on the two adjacent sides of the shovel plate and the shovel plate, eight fixed plates 3 and eight movable plates 4 are welded, and the fixed plates 3 and the movable plates 4 are separated by a certain distance to form a Hollow cavity structure, eight sets of wire brushes are respectively fixed in the hollow cavity formed by the fixed plate 3 and the movable plate 4 through bolts 5 . There are also ten countersunk holes 6 on the connecting plate 1, and the countersunk holes 6 are matched with the holes on the scraper plate of the bucket frame body of the grooving machine. on board. according to figure 1 As shown, the present embodiment is di...

Embodiment 2

[0025] Embodiment two: if Figure 5-7 As shown, two semicircular fixed plates 3 are welded on the vertical direction of the connecting plate 1, and the other two plates are movable plates 4, a hollow cavity structure is formed between the two plates, and the wire brush is installed in the hollow through the bolt 5. inside the cavity. The connecting plate 1 is provided with a countersunk hole 6 for affixing with the slotting machine. According to Fig. 10, the installation of upper and lower two layers of wire brushes shown in Figure 11 all is finished by fixed plate 3, mobile plate 4 of same specification.

[0026] The second embodiment is actually implemented: this embodiment is used for joints with curved sections in the joints of underground diaphragm walls. The semicircular fixing plate used in this embodiment is used to brush the curved surface structure of the underground diaphragm wall joint. Since the wall surface of the curved surface structure is simple in processin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com