Engine-driven generator

An engine-driven, generator technology, applied in the direction of engine control, engine frame, machine/engine, etc., can solve the problems of reducing the size, weight and cost of the whole machine, fuel tank occupancy, occupancy, etc., to increase aesthetics, reduce The effect of size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

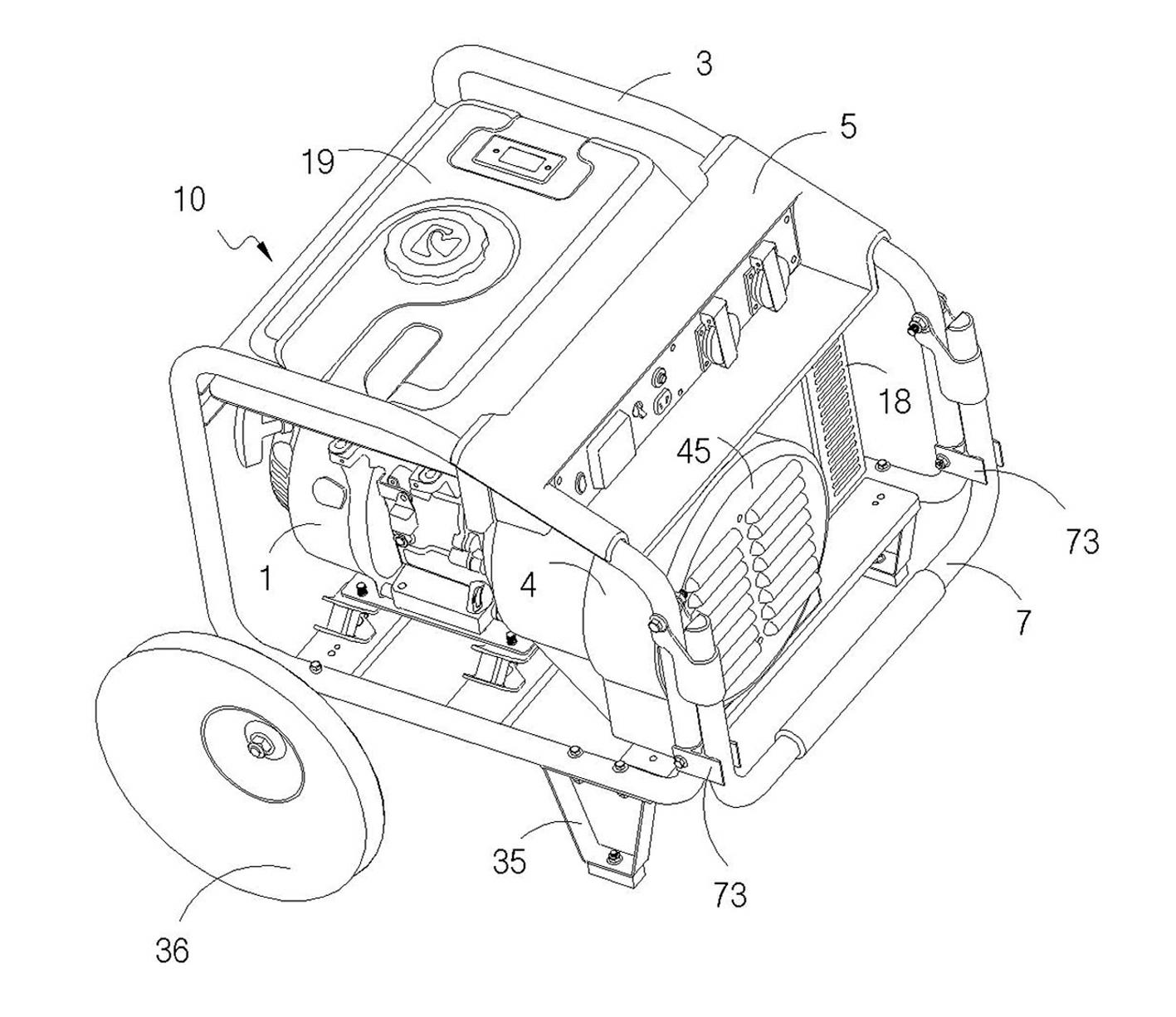

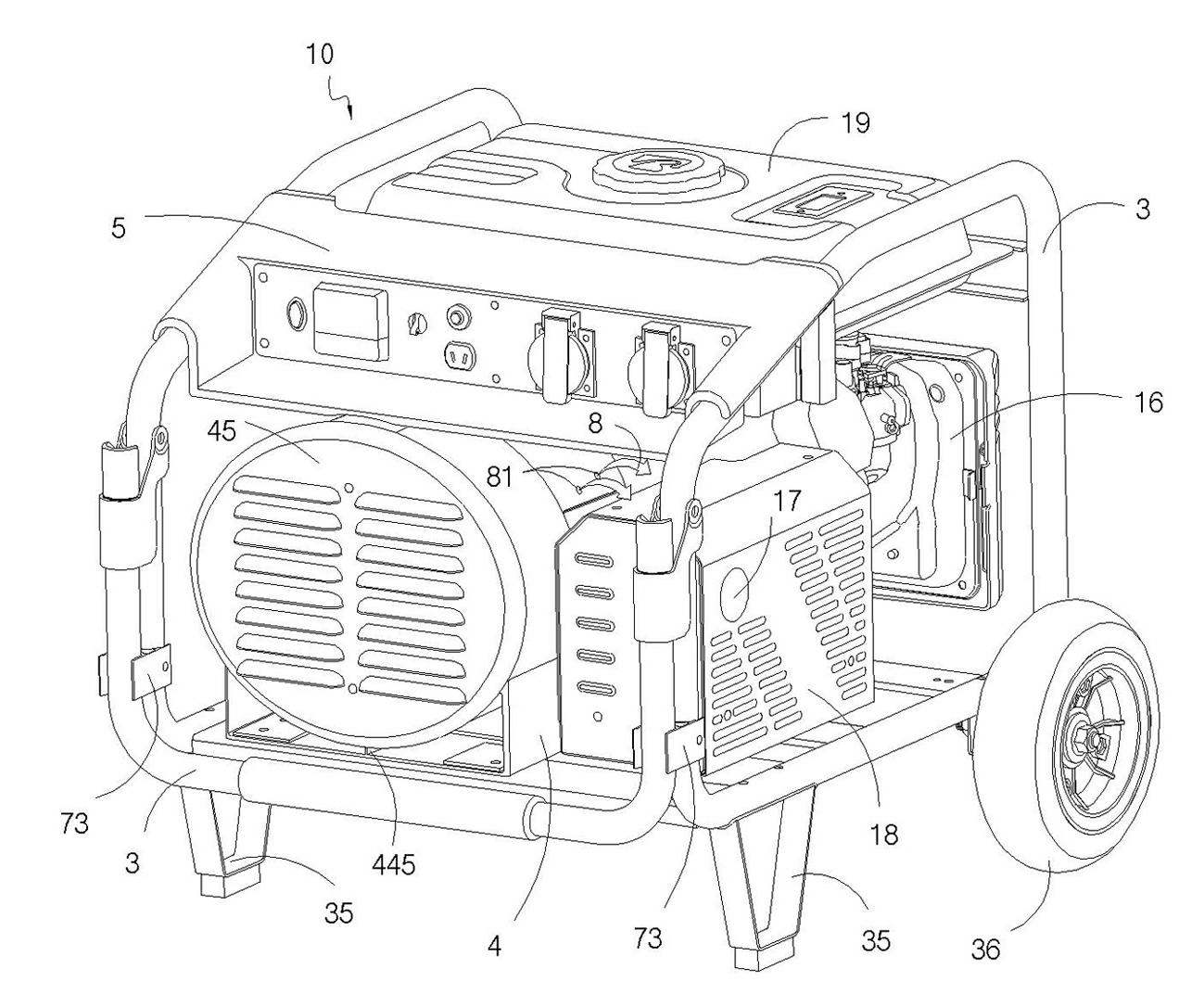

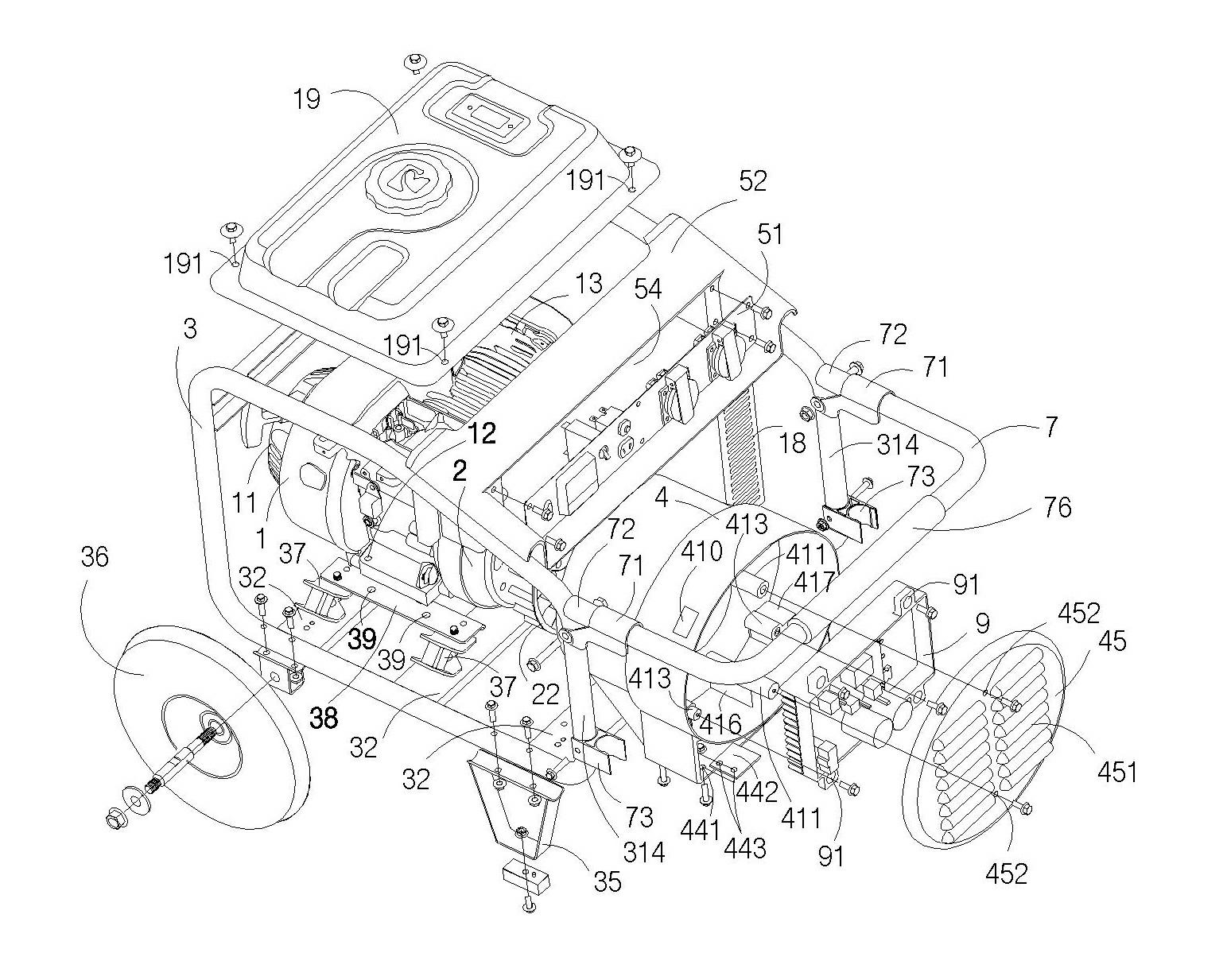

[0026] Next, when describing the embodiment of the present invention with reference to the accompanying drawings, the direction in which the handle 7 pulls the engine-driven generator 10 is taken as the front.

[0027] Such as figure 1 , image 3 As shown, the engine-driven generator 10 has: a frame 3 forming a supporting frame of the engine-driven generator 10; an engine 1 and a generator 2 coaxially driven by the engine 1, both elastically supported on the frame 3 The generator 2 is connected with a motor fan 22; the fuel tank 19 provides fuel for the engine 1; the electrical unit 9 controls the current output, and in an embodiment, the electrical unit 9 refers to the inverter (of course, except Inverter, also can comprise other electrical components); Control unit 5, it is installed in the space between two inclined sections 312b, 312b above frame 3 (referring to Figure 4 ), used to control the operation of the engine-driven generator 10; the cooling shell 4, used to gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com