Hose reinforcing composite rope made of contraposition aromatic polyamide fibers

An aramid and fiber-reinforced technology is applied in the field of hoses reinforced with composite ropes of para-aramid fibers, and can solve the problems of inability to provide the hose with burst pressure and volume expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

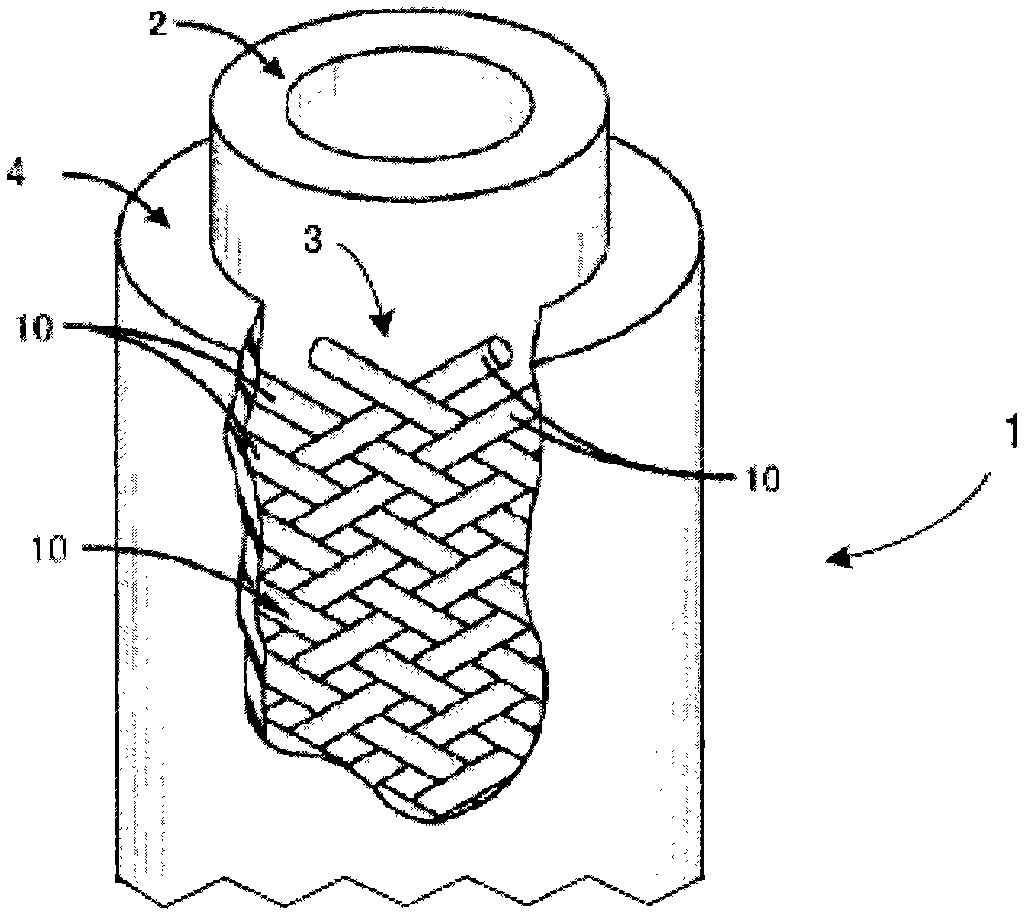

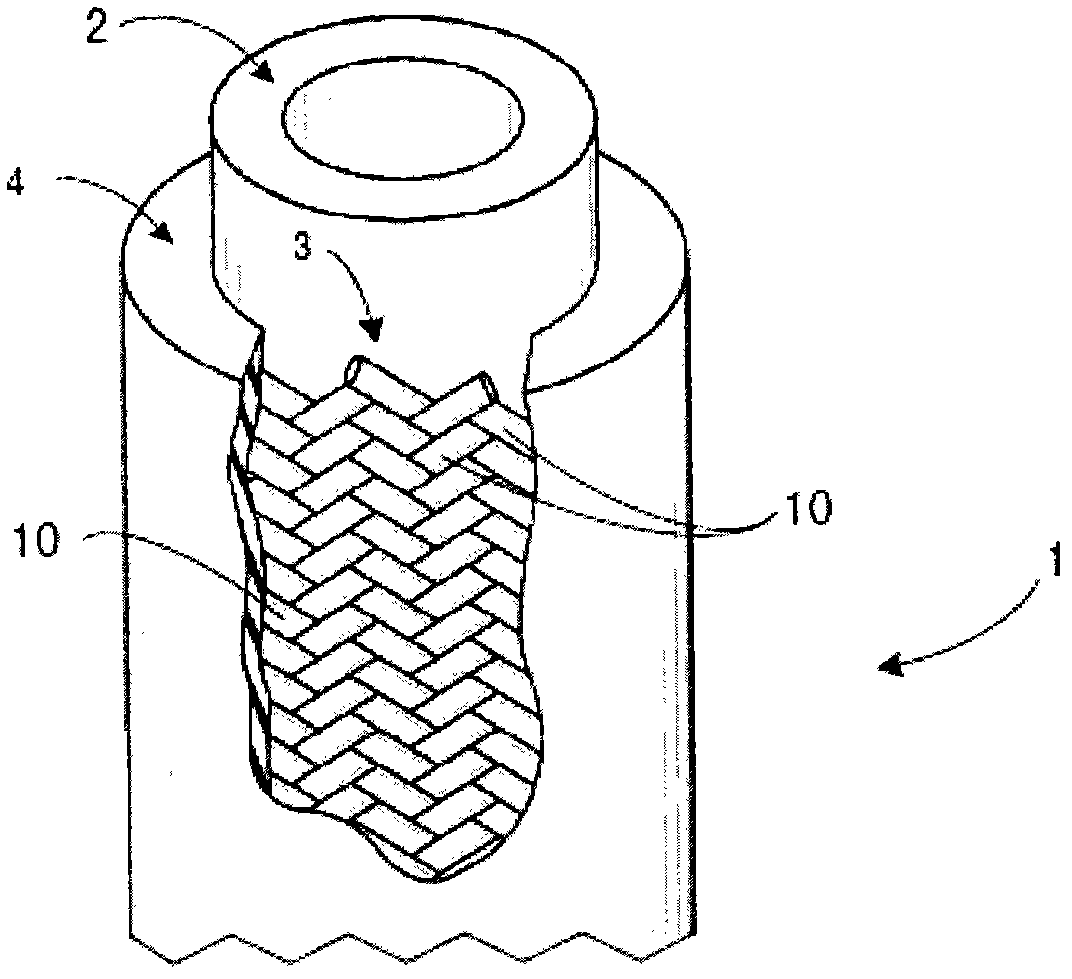

[0062] There are no special restrictions on the preparation method of the hose of the present invention, and the processes and steps for preparing the hose known to those of ordinary skill in the art can be used, as long as it is satisfied that only a single layer of fiber formed by the composite rope of the present invention is used in the hose. Enhancement layer. For example, the hose of the present invention can be formed as follows: at least one elastic substrate tube core layer is formed by an extrusion process, and then the composite rope of the present invention is used on the tube core layer to form a single-layer fiber reinforced layer, and then passed through The extrusion process forms at least one elastic base material outer coating on the fiber reinforced layer.

[0063] The hose of the present invention can be used for a hose assembly, and the hose assembly includes the hose of the present invention, hose connectors and clamps sleeved at both ends of the hose.

[006...

Embodiment 1

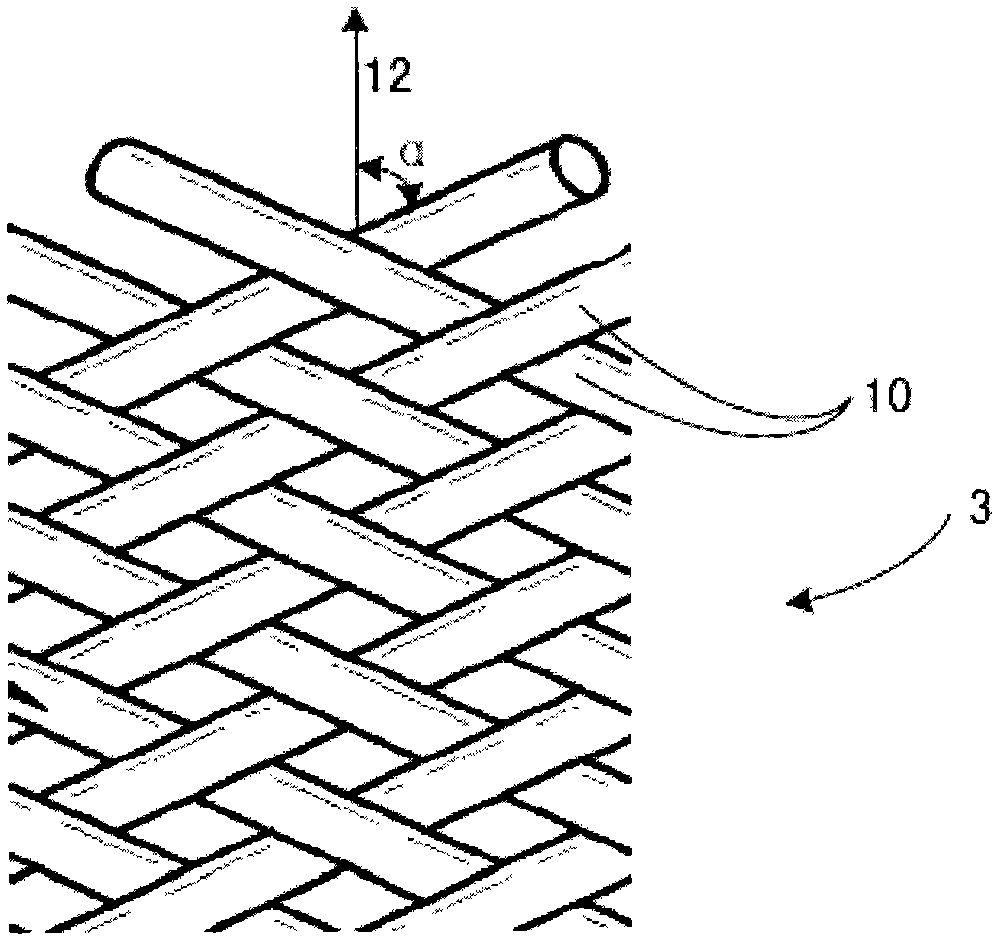

[0083] Put a 600 denier Kevlar 1K1668 fiber and a strand of 500 denier polyester fiber are twisted in the same direction to 693 twists / meter, then they are combined and twisted in the opposite direction to 693 twists / meter to form a composite rope (Such as Image 6 ), the twisting coefficient of the composite rope is about 8. Then, the two twisted composite ropes are paralleled and stranded, and then the four composite ropes after the parallel stranding are wound on each spindle in parallel and braided into the hose. The single-layer fiber reinforced layer has an interlaced pattern of eight parallel composite ropes.

Embodiment 2

[0085] Two 600-denier Kevlar 1K1668 fibers were twisted in the same direction to a twist of 697 twists / meter, and a 500-denier polyester fiber was also twisted in the same direction to a twist of 697 twists / meter, and then These three strands of fibers are merged together and twisted in opposite directions to a twist of 697 twists / meter to form a composite rope (such as Figure 7 ), the twisting coefficient of the composite rope is about 10. Two twisted composite ropes are twisted, and then three parallel twisted composite ropes are wound on each spindle in parallel, and are braided into a hose. The single-layer fiber reinforced layer has an interlaced pattern of six parallel composite ropes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume expansion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com