Stainless steel wire strengthened structure of polytetrafluoroethylene flexible pipe assembly with 35MPa pressure rating

A technology of polytetrafluoroethylene and stainless steel wire, applied in the direction of hose, pipe/pipe joint/pipe fitting, pipe, etc., can solve the problem of not meeting the pressure level requirements, and achieve the effect of improving the overall pressure resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

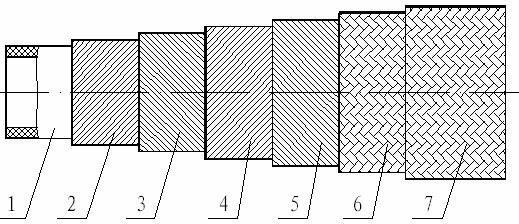

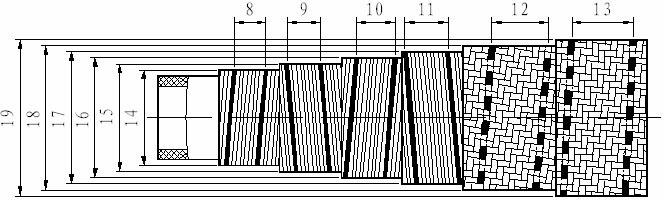

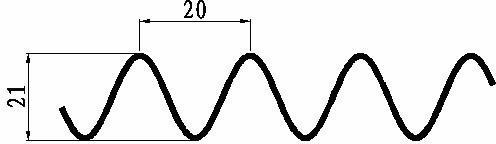

[0033] Example 1: The stainless steel wire reinforcement structure of the 35MPa pressure grade polytetrafluoroethylene hose assembly consists of a polytetrafluoroethylene inner tube 1, a first stainless steel wire winding structure 2, a second stainless steel wire winding structure 3, and a third stainless steel wire winding structure 4. The fourth stainless steel wire winding structure 5, the first stainless steel wire weaving structure 6, and the second stainless steel wire weaving structure 7, wherein: the first stainless steel wire winding structure 2, the second stainless steel wire winding structure 3, and the third stainless steel wire winding structure The structure 4 and the fourth stainless steel wire winding structure 5 are sequentially attached to the outer surface of the polytetrafluoroethylene inner tube 1, and the first stainless steel wire braiding structure 6 and the second stainless steel wire braiding structure 7 are sequentially attached to the fourth stainle...

Embodiment 2

[0043] Example 2: The stainless steel wire reinforcement structure of the 35MPa pressure grade polytetrafluoroethylene hose assembly consists of a polytetrafluoroethylene inner tube 1, a first stainless steel wire winding structure 2, a second stainless steel wire winding structure 3, and a third stainless steel wire winding structure 4. The fourth stainless steel wire winding structure 5, the first stainless steel wire weaving structure 6, and the second stainless steel wire weaving structure 7, wherein: the first stainless steel wire winding structure 2, the second stainless steel wire winding structure 3, and the third stainless steel wire winding structure The structure 4 and the fourth stainless steel wire winding structure 5 are sequentially attached to the outer surface of the polytetrafluoroethylene inner tube 1, and the first stainless steel wire braiding structure 6 and the second stainless steel wire braiding structure 7 are sequentially attached to the fourth stainle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com