Radiating structure

A heat dissipation structure and heat dissipation end technology, applied in lighting and heating equipment, cooling/heating devices of lighting devices, lighting devices, etc., to reduce weight, facilitate design and shape, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

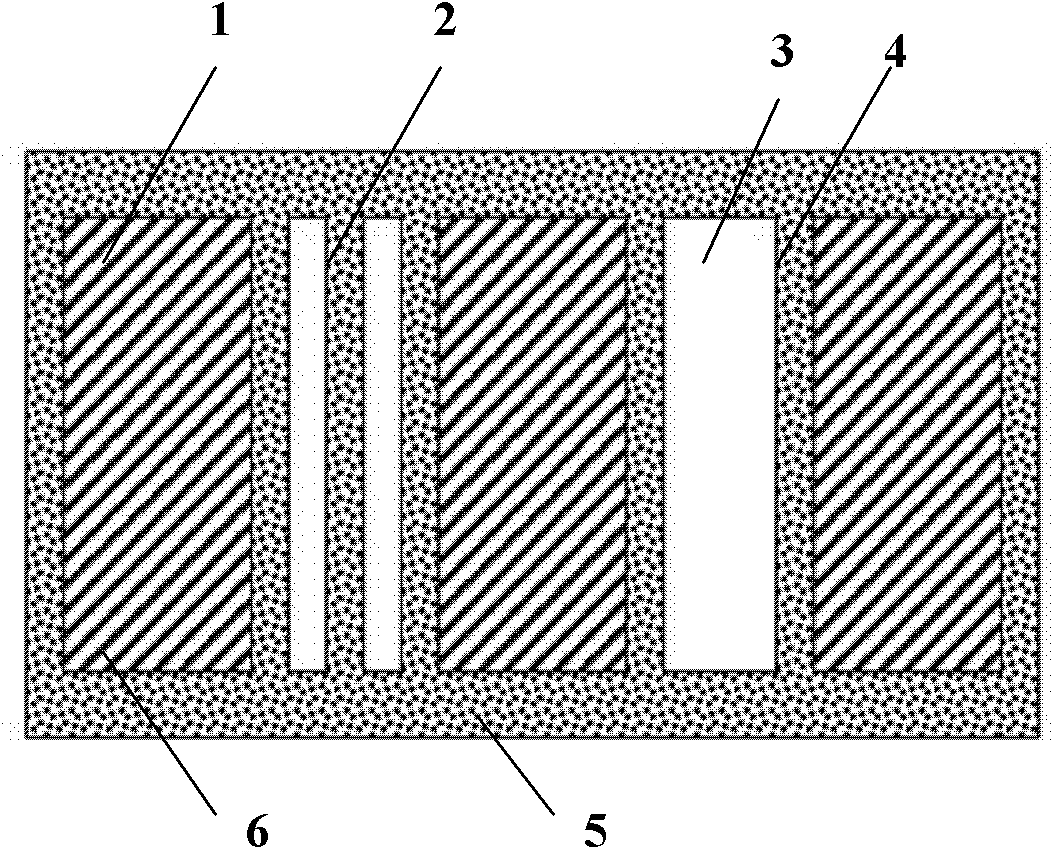

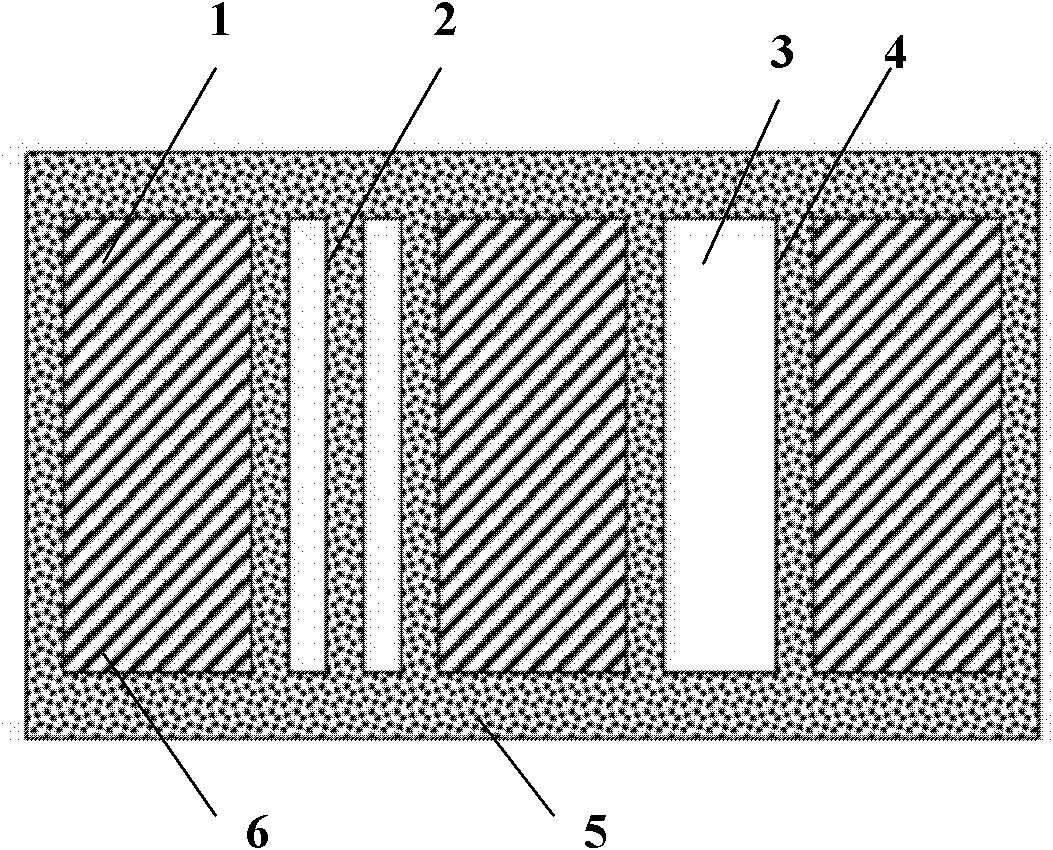

[0018] Embodiment one, see figure 1 , a heat dissipation structure, comprising a heat absorption end 6, a heat dissipation end 1, a heat conduction layer 5 is provided on the surface of the heat absorption end 6 and the heat dissipation end 1, a heat dissipation channel 3 is provided between the heat absorption end 6 and the heat dissipation end 1, and the heat dissipation channel The inner wall of 3 is provided with a heat conduction layer 4, and the heat dissipation channel 3 can be designed as a groove or a hole. The heat dissipation channel 3 is filled with a heat conducting material 2 . The heat conducting material 2 and the heat conducting layers 4 and 5 are soft ceramics or heat conducting silica gel. The heat-absorbing end 6 and the heat-dissipating end 1 are made of heat-resistant insulating material, such as plastic, or nylon, or rubber.

Embodiment 2

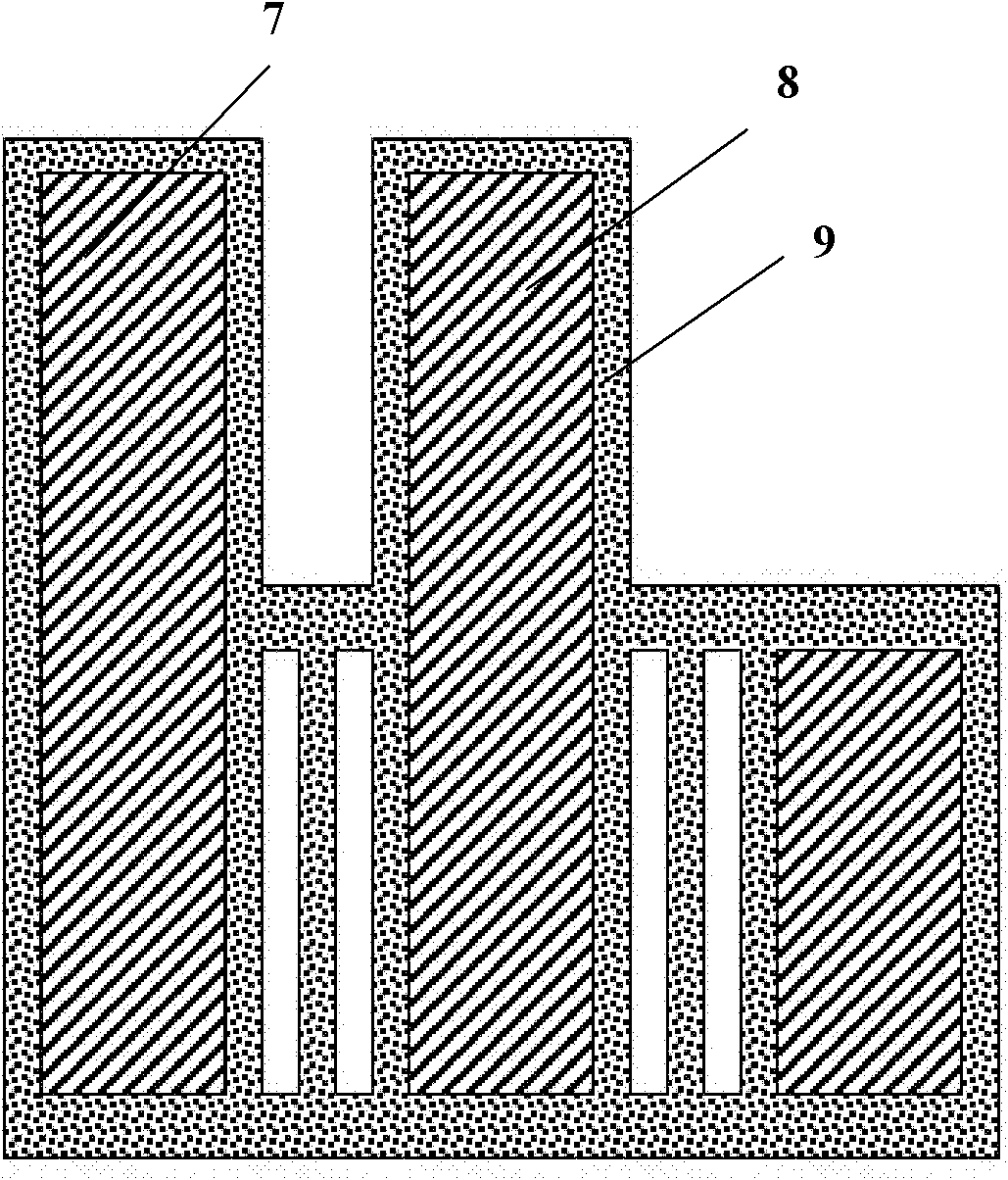

[0019] Embodiment two, see figure 2 , which is different from Embodiment 1 in that the heat dissipation end is provided with heat dissipation fins 7, 8, and the styles of the fins can be made into various styles according to requirements; the fins 7, 8 are made of heat-resistant insulating materials, such as plastics, or Nylon or rubber; the surface of the fins 7 and 8 is provided with a heat conduction layer 9, and the heat conduction layer 9 is soft ceramic or heat conduction silica gel.

[0020] The above-mentioned embodiments do not use metal materials such as aluminum and copper as heat dissipation materials, but use high thermal conductivity materials such as soft ceramics as heat dissipation materials, and such materials are suitable as coatings, so hard materials are required as radiator skeletons. Considering the skeleton It only plays a supporting role and does not need to participate in heat dissipation. Considering insulation, heat-resistant insulating materials s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com