Coordinative control method for supercritical unit boilers quickly adaptive to change of heat value of fire coal

A supercritical unit, coal-fired calorific value technology, applied in control systems, lighting and heating equipment, steam generation, etc., can solve the problems of unstable operation of the fuel control system, fuel changes, etc., and achieve fast and real-time coal-fired calorific value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

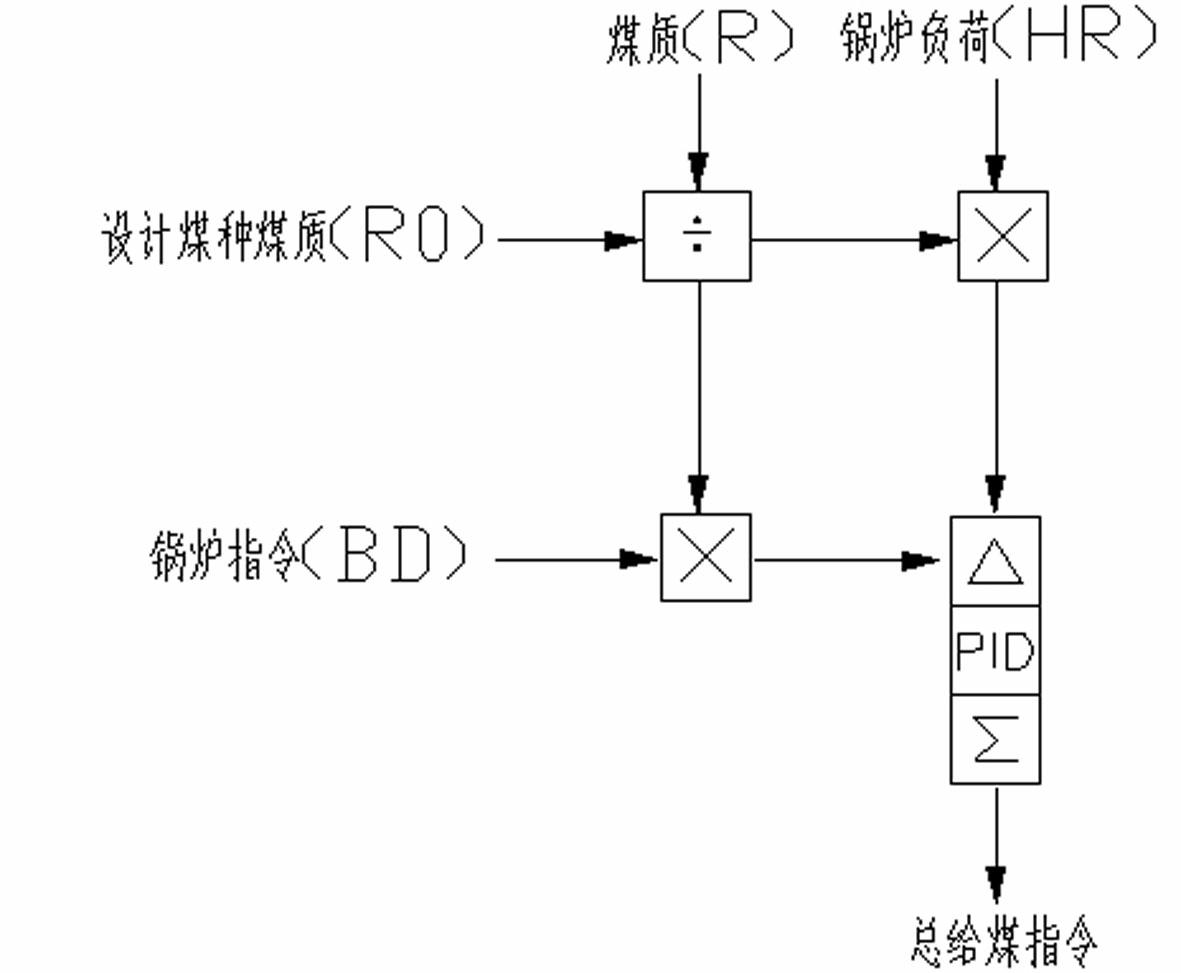

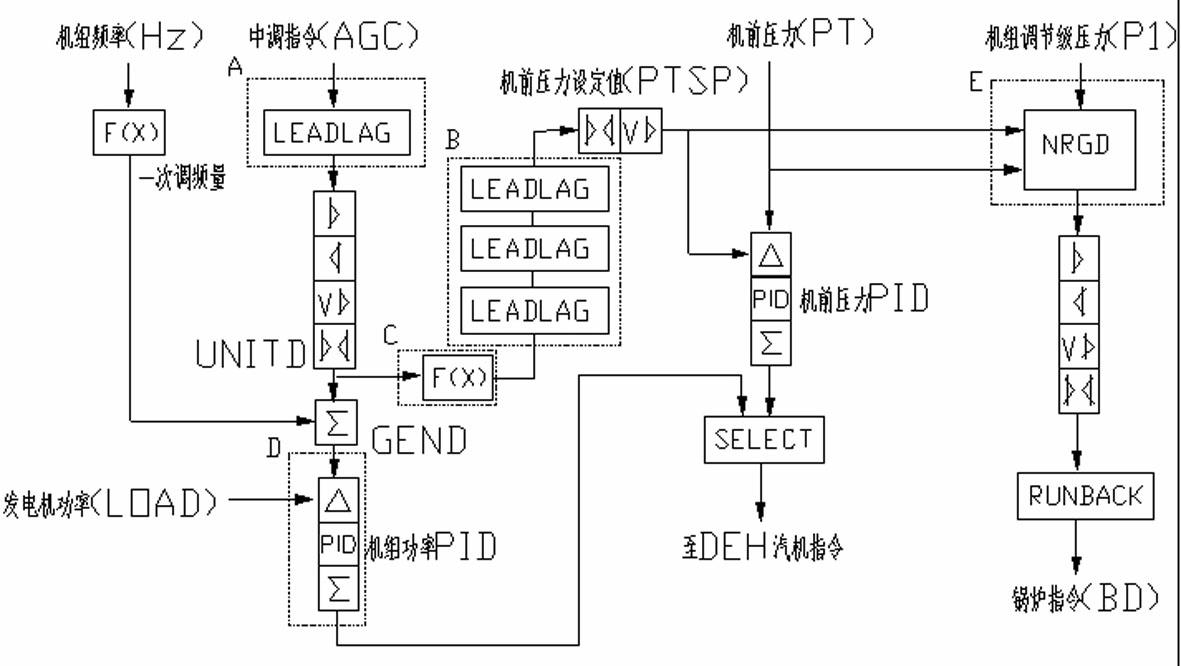

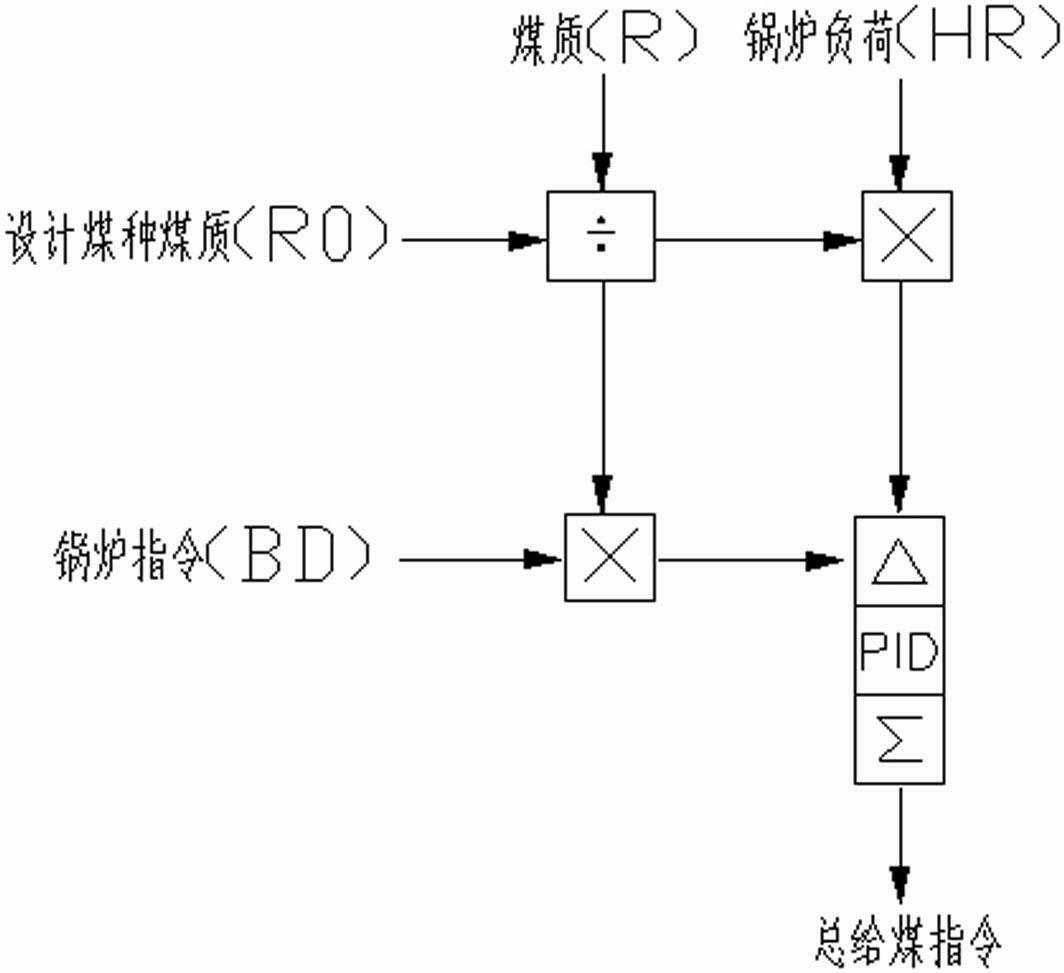

[0042] See figure 1 , figure 2 , a method for coordinating control of supercritical unit machine furnaces for fast adaptive coal calorific value changes, the method includes the following steps:

[0043] The parameters representing the change of the calorific value of coal combustion are comprehensively and quickly calculated from the steam turbine regulating stage pressure, steam-water separator pressure, coal feed rate, and unit load parameters;

[0044] By calculating the ratio of the boiler heat signal to the inertia link of the coal quantity and the time delay, after filtering, it can quickly represent the coal combustion calorific value parameter:

[0045] ) (1)

[0046] HR—heat signal (MW);

[0047] M—coal supply, t / h;

[0048] - filter module;

[0049] LEADLAG—inertial link module;

[0050] τ—lag time, s;

[0051] R—coal calorific value parameter;

[0052] The heat signal uses a conventional algorithm:

[0053] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com