Technology for liquefying chlorine through medium-temperature and medium-pressure method

A chlorine gas and medium temperature technology, applied in the field of liquefaction, can solve the problems of difficult discovery of liquefiers and high power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

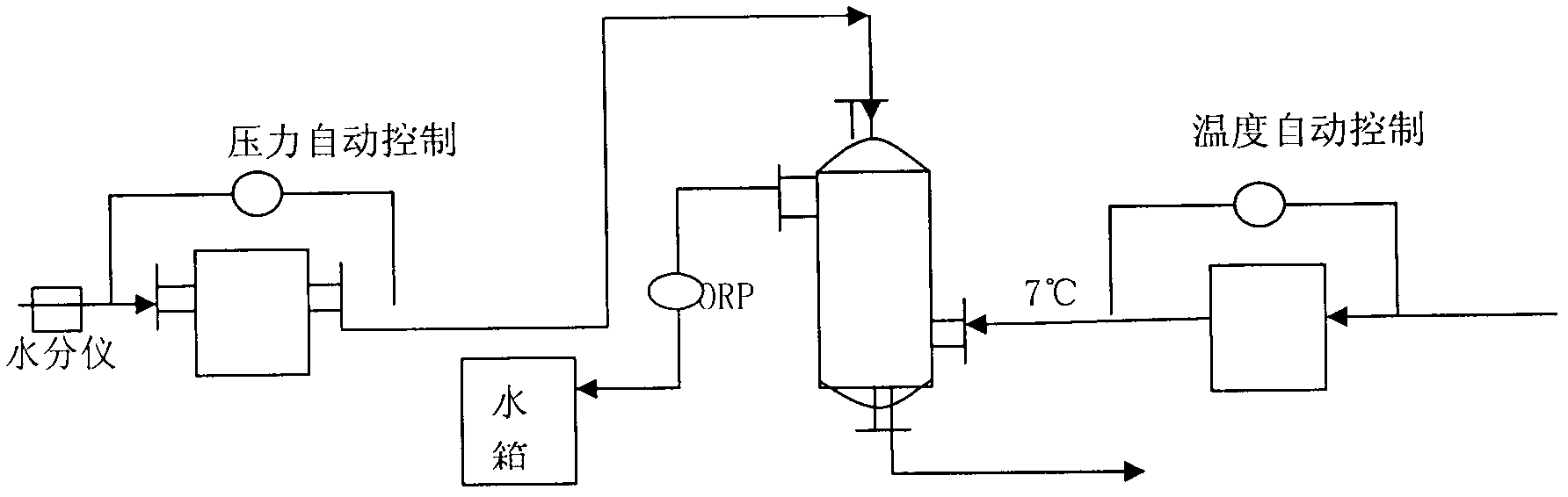

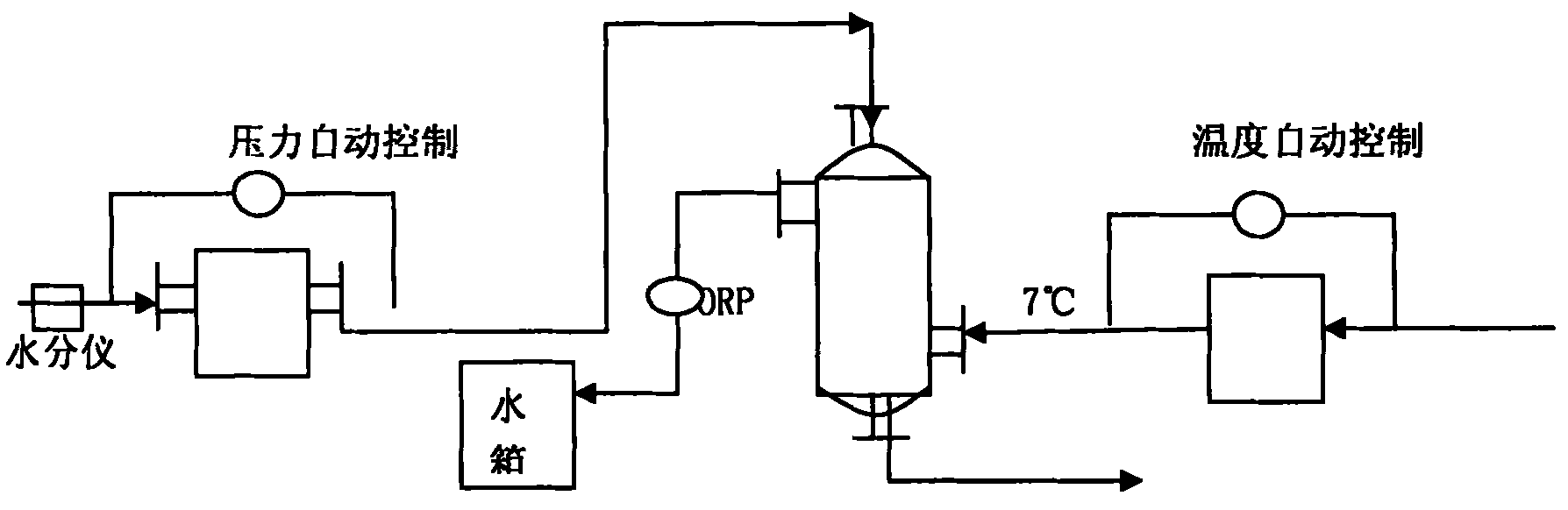

[0005] Referring to the figure, the medium-temperature and medium-pressure liquefied chlorine technology is that the electrolytic chlorine gas is dried and then pressurized to 7kgf / cm by a compressor. 2 After entering the liquefier, 92% of the chlorine gas is liquefied after being cooled by 7°C cooling water. The liquefier is cooled by pure water at 7°C, and the cooling capacity is provided by a steam refrigeration unit, using waste steam from a thermoelectric steam engine as a cooling source. An ORP online monitor is installed in the cooling return water of the liquefier. The unit is equipped with a temperature control system to ensure that the temperature of the cold water is kept at 7-8°C, thereby ensuring the stability of the system's pressure and purity. It also completely eliminated the root cause of the explosion accident in Chongqing Tianyuan Chemical Plant. The ORP online monitor is installed in the cooling return water of the liquefier to monitor the working status...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com