Longitudinal flow shell-and-tube heat exchanger

A flow tube and heat exchanger technology, applied in the field of longitudinal flow shell-and-tube heat exchangers, can solve the problems of heat transfer enhancement fluid and tube bundle surface shear force, increase of friction fluid dissipation work, etc., to achieve enhanced axial Degree of mixing and turbulence, low power consumption, effect of increased turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

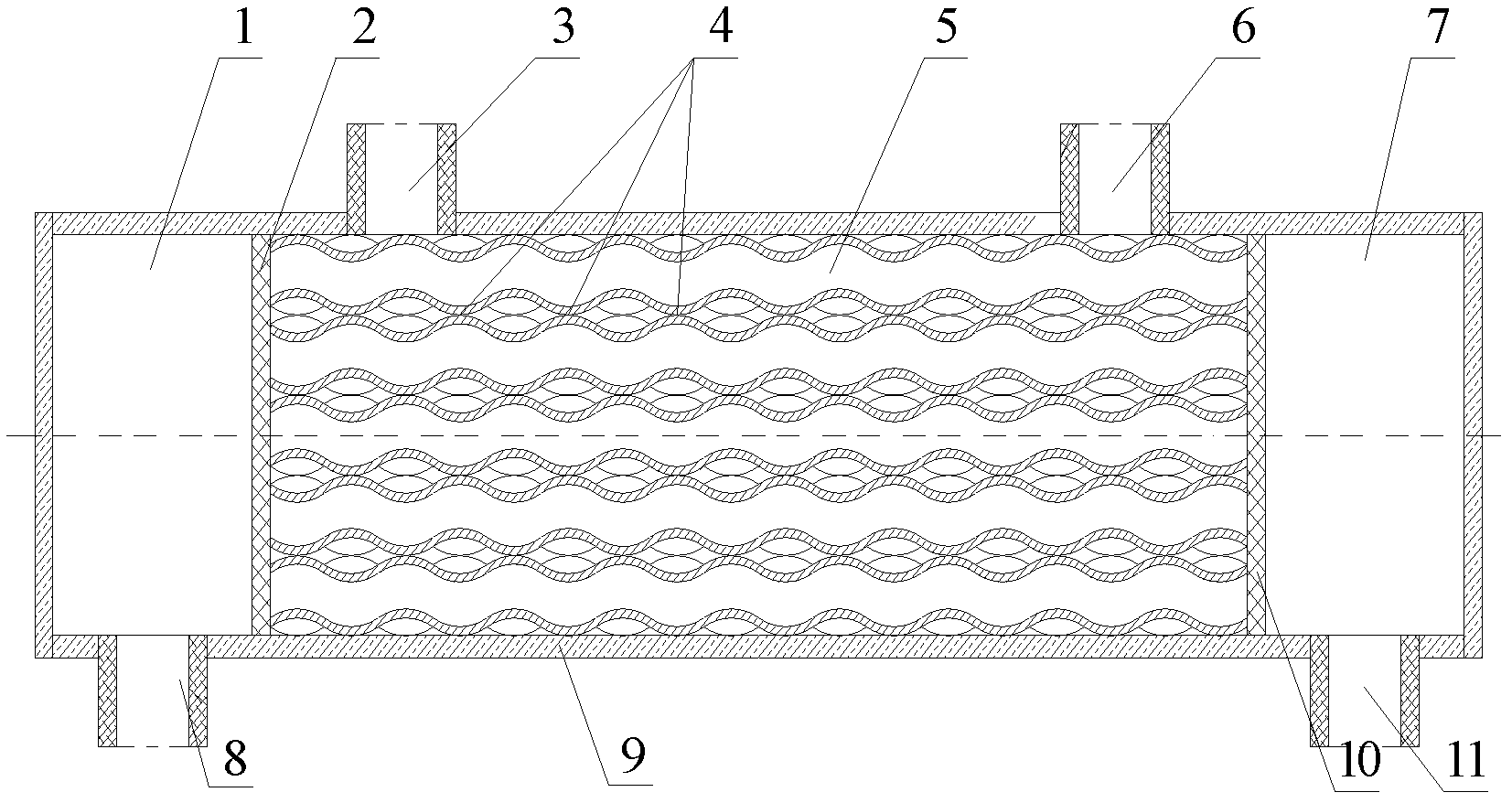

[0026] Such as figure 1 As shown, the first embodiment of the present invention includes a housing 9, a left tube plate 2, a right tube plate 10, a left head 1 and a right head 7, and the side wall of the housing has a shell side inlet 3 and a shell side outlet 6. The shell 9 is provided with a left tube plate 2 and a right tube plate 10 respectively. The 21 heat transfer tubes 5 pass through the left and right tube plates and are fixed by the left and right tube plates. The head 7 is closed, and the left and right heads are respectively provided with a tube side inlet 11 and a tube side outlet 8, and the tube side inlet and outlet and the shell side inlet and outlet are arranged in reverse.

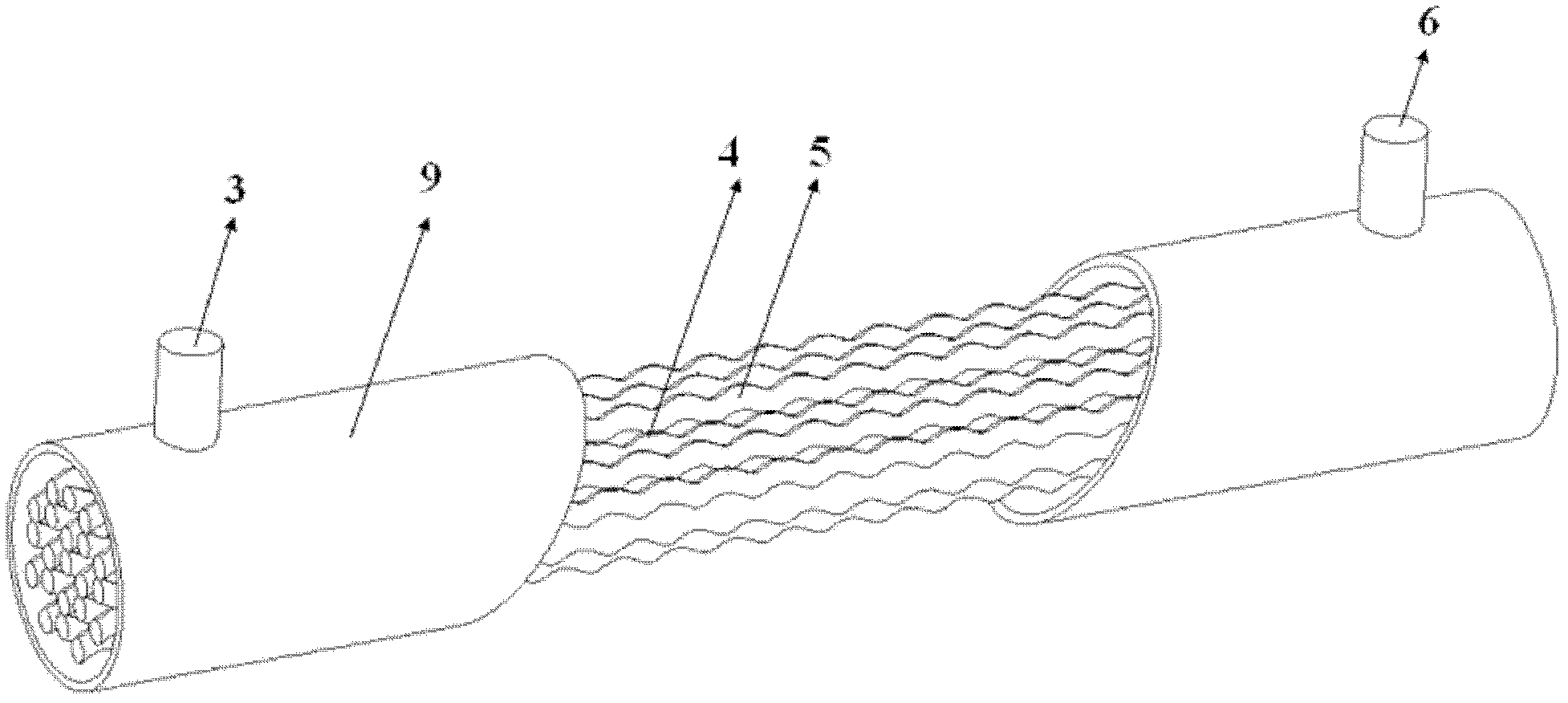

[0027] Such as figure 2 As shown in the first embodiment, the left and right tube plates and the shell parts of the left and right heads are removed. The figure only shows the shell side inlet 3, the shell side outlet 6, the heat transfer tube 5 and the shell 9; the inner diameter of the sh...

Embodiment 2

[0034] The second embodiment, the structure is the same as the first embodiment, the 12 heat transfer tubes pass through the left and right tube plates and are fixed by the left and right tube plates, the inner diameter of the shell is 9.5mm, and the wall thickness of the shell is 1mm;

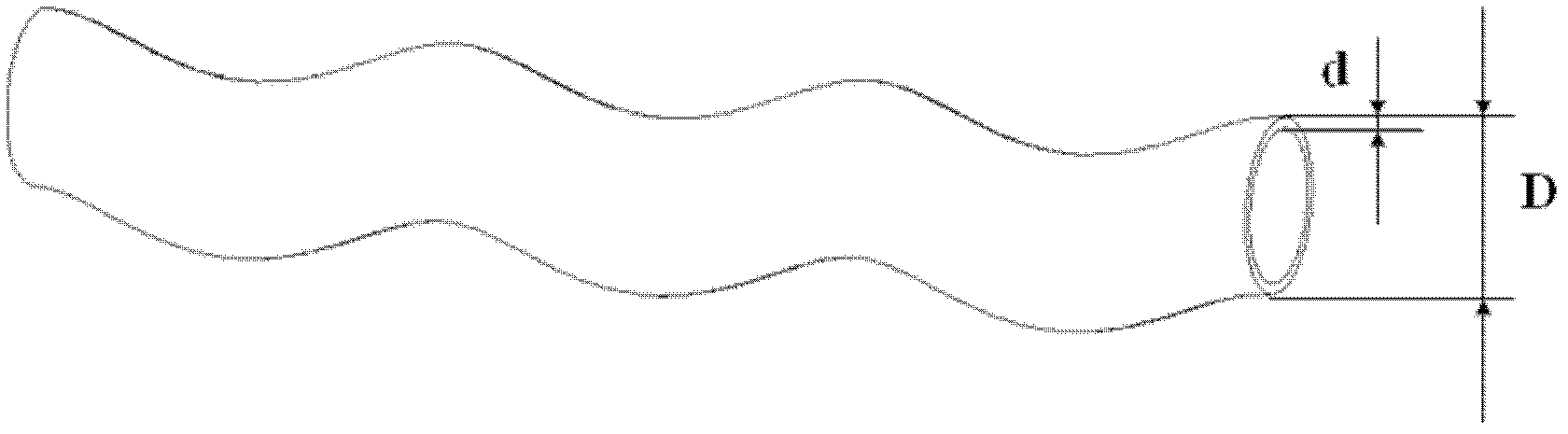

[0035] Any cross-sectional shape of the spiral heat transfer tube is a circle with equal radius, the inner diameter D of the spiral heat transfer tube is 1.4mm, and the wall thickness d is 0.2mm; the central axis of the spiral heat transfer tube is a cylindrical helix. The following conditions are met in the Cartesian coordinate system:

[0036] x=a×cosθ,

[0037] y=a×sinθ,

[0038] z=S×θ / 2π,

[0039] Among them, x, y, z are the coordinates of each point on the cylindrical spiral line in the Cartesian coordinate system of the x, y, and z axis central axis, z is 100mm, the variable θ is the angle, the spiral radius a is 0.25mm, The distance S is 4mm.

Embodiment 3

[0040] The third embodiment, the structure is the same as the first embodiment, 480 heat transfer tubes pass through the left and right tube plates and are fixed by the left and right tube plates, the inner diameter of the shell is 4180mm, and the wall thickness of the shell is 100mm;

[0041] Any cross-sectional shape of the spiral heat transfer tube is a circle with equal radius, the inner diameter D of the spiral heat transfer tube is 140mm, and the wall thickness d is 20mm; the central axis of the spiral heat transfer tube is a cylindrical helix. The following conditions are met in the coordinate system:

[0042] x=a×cosθ,

[0043] y=a×sinθ,

[0044] z=S×θ / 2π,

[0045] Among them, x, y, z are the coordinates of each point on the cylindrical spiral line in the Cartesian coordinate system of the x, y, and z axis central axis, z is 20000mm, the variable θ is the angle, the spiral radius a is 25mm, and the pitch S is 400mm.

[0046] Figure 5 ~ Figure 10 For the results of numerical si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com