Automobile transmission vibration analysis testing method and device

A technology for automobile transmission and vibration analysis, applied in the direction of machine gear/transmission mechanism testing, measuring devices, instruments, etc., can solve the problems of unretrieved patent applications, difficulties in time, cost and customer satisfaction, and high cost, and achieves satisfactory results. Reliability testing, easy service and maintenance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

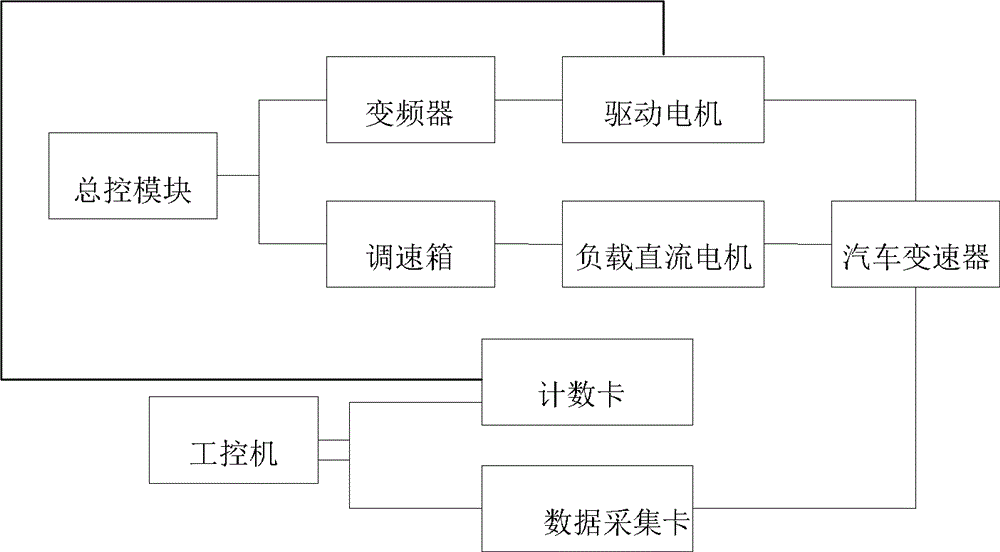

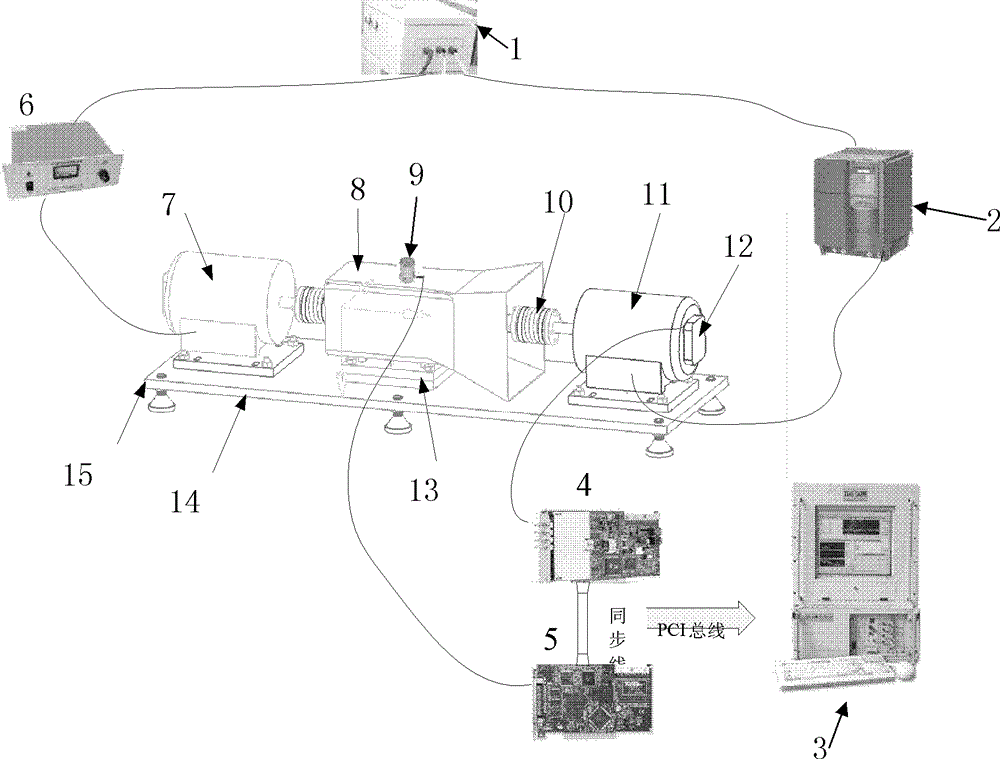

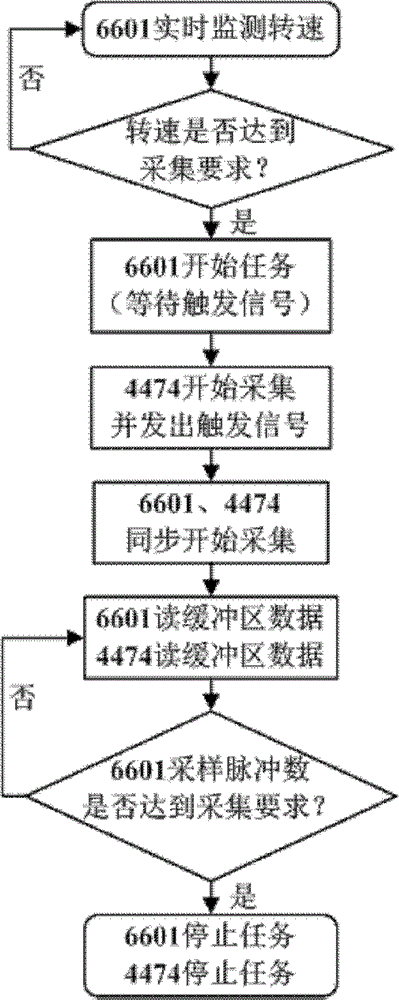

[0033] Such as figure 1 As shown, a vibration analysis test device for an automobile transmission includes: a base 14, a master control module 1, a frequency converter 2, a governor 6, a drive motor 11, a load DC motor 7, an automobile transmission 8, an industrial computer 3, and a data Acquisition card 5, counting card 4; The output terminal of the master control module 1 is connected with the frequency converter 2, and is also connected with the speed control box 6; The frequency converter 2 is connected with the automobile transmission 8 through the driving motor 11; The frequency converter 2 controls And adjust the driving motor 11 rotating speeds. The speed control box is connected with the automobile transmission 8 through the load DC motor 7; the speed governor 6 controls and adjusts the torque of the load DC motor 7; the automobile transmission 8 is used for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com