Method for removing water from ionic liquid alcoholic solution

A technology of ionic liquids and acidic ionic liquids, applied in chemical instruments and methods, preparation of organic compounds, catalysts of organic compounds/hydrides/coordination complexes, etc. Poor performance and other problems, to achieve the effect of reducing energy consumption and meeting operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

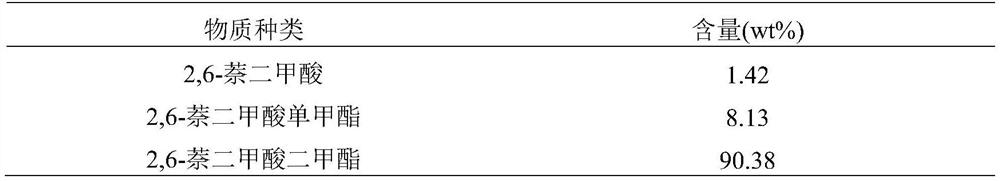

Embodiment 1

[0038] Take by weighing 300g ethanol, 21g water and 9g 1-methyl-3-propanesulfonic acid imidazolium bisulfate ([MPSIm][HSO 4 ]) is configured as an initial ionic liquid alcohol solution, and the pH value of the ionic liquid alcohol solution is 0.71 at this moment. Add 1.31 g of diethylamine to the prepared ionic liquid alcohol solution at 10° C. to adjust the pH of the system to 5.21. The adjusted ionic liquid alcohol solution enters the pervaporation unit, wherein the pervaporation membrane is a molecular sieve membrane. Under the operating conditions of 40° C. and permeation side pressure of 200 Pa, the dehydration was circulated in the pervaporation unit for 4 hours to obtain the ionic liquid alcohol solution after water removal. The ionic liquid alcohol solution after water removal was heated to reflux at 60° C., the temperature of the condensation column was 40° C., and the final product was obtained after 1 hour. The water content in the system measured by a Karl Fische...

Embodiment 2

[0042] Take by weighing 300g ethanol, 21g water and 9g 1-methyl-3-propanesulfonic acid imidazolium bisulfate ([MPSIm][HSO 4 ]) is configured as an initial ionic liquid alcohol solution, and the pH value of the ionic liquid alcohol solution is 0.71 at this moment. Add 3.00 g of triethylamine to the prepared ionic liquid alcohol solution at 10° C. to adjust the pH of the system to 6.72. The adjusted ionic liquid alcohol solution enters the pervaporation unit, wherein the pervaporation membrane is a molecular sieve membrane. Under the operating conditions of 40° C. and permeation side pressure of 200 Pa, the dehydration was circulated in the pervaporation unit for 4 hours to obtain the ionic liquid alcohol solution after water removal. The ionic liquid alcohol solution after water removal was heated to reflux at 65° C., the temperature of the condensation column was 40° C., and the final product was obtained after 1 hour. The water content in the system measured by a Karl Fisch...

Embodiment 3

[0044] Take by weighing 300g ethanol, 21g water and 9g 1-methyl-3-propanesulfonic acid imidazolium bisulfate ([MPSIm][HSO 4 ]) is configured as an initial ionic liquid alcohol solution, and the pH value of the ionic liquid alcohol solution is 0.71 at this moment. Add 2.87 g of dimethyl sulfoxide to the prepared ionic liquid alcohol solution at 10° C. to adjust the pH of the system to 7.89. The adjusted ionic liquid alcohol solution enters the pervaporation unit, wherein the pervaporation membrane is a molecular sieve membrane. Under the operating conditions of 40° C. and permeation side pressure of 200 Pa, the dehydration was circulated in the pervaporation unit for 4 hours to obtain the ionic liquid alcohol solution after water removal. The ionic liquid alcohol solution after water removal was heated to reflux at 60° C., the temperature of the condensation column was 40° C., and the final product was obtained after 1 hour. The water content in the system measured by a Karl ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com