No.0 high-pressure heater optimization control system based on multi-data judgment

An optimized control and multi-data technology, which is applied in heating systems, heating methods, lighting and heating equipment, etc., can solve the problem of primary frequency modulation ability not being tested and applied, environmental protection contribution not being thoroughly investigated and analyzed, No. 0 high plus Without economic analysis and other issues, the effect of improving environmental protection level, realizing economic value and meeting operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The specific implementation of the present invention will be described in further detail below in conjunction with the examples.

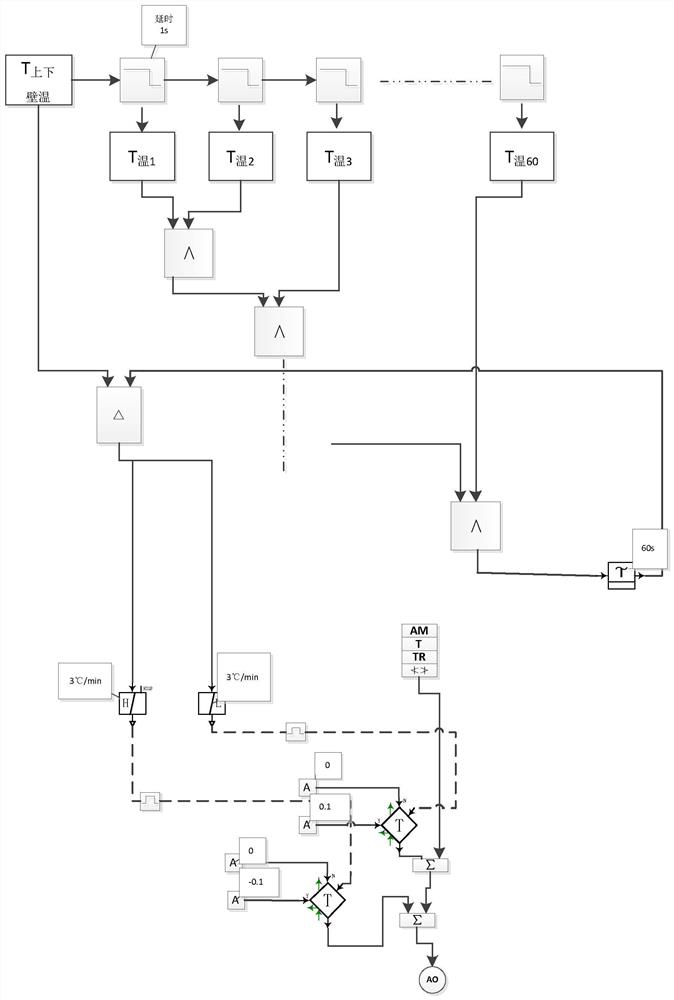

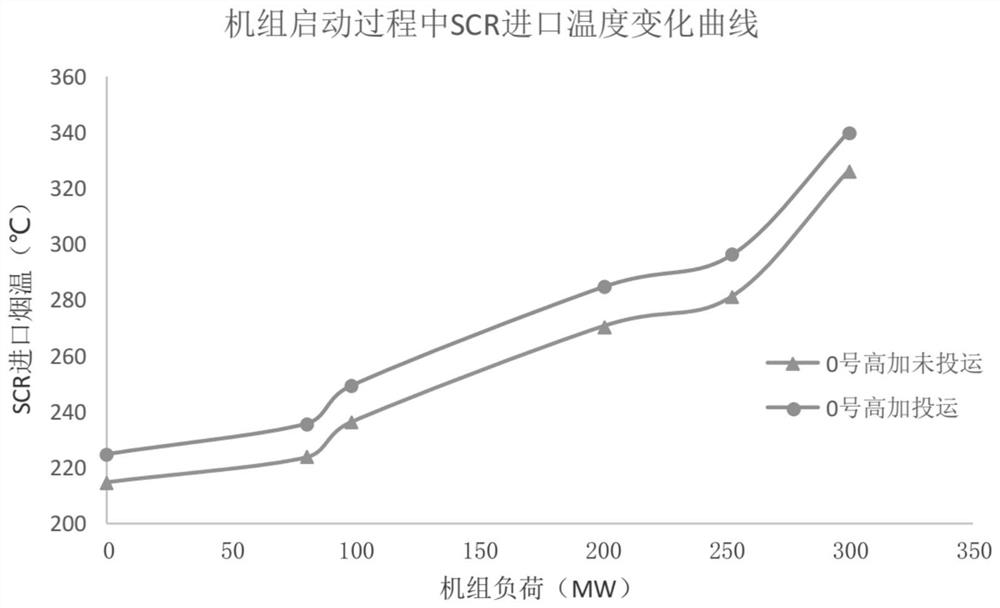

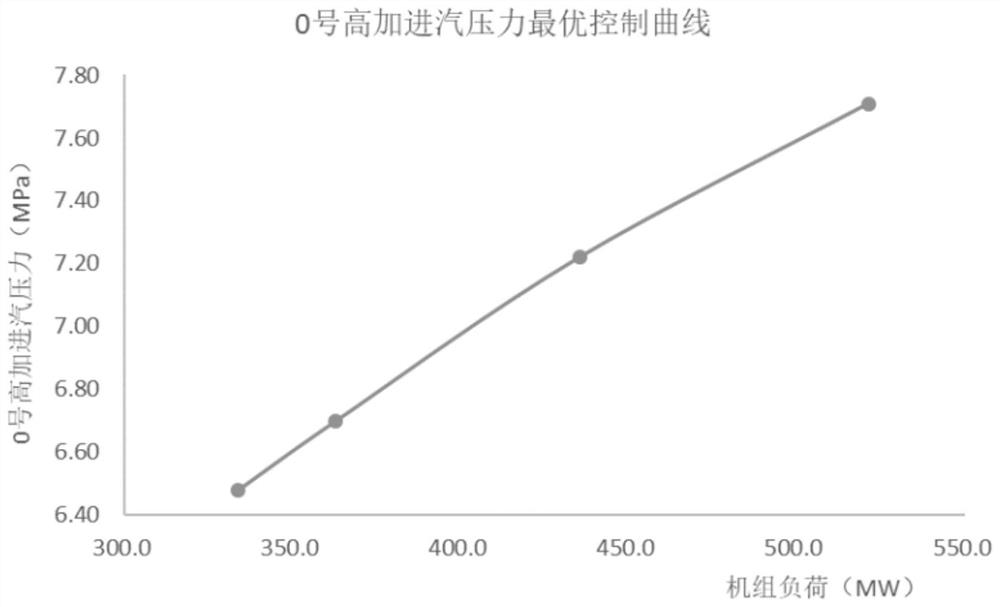

[0053] According to the present invention, a No. 0 height optimization control system based on multi-data judgment includes 4 control levels, which are heating pipe control level, environmental protection control level, economic control level and primary frequency modulation control level. After the unit is started and connected to the grid, No. 0 high-pressure heater (No. 0 high-pressure heater referred to as "No. Temperature (0 stage extraction temperature referred to as "0 pumping temperature"), No. 0 high gas outlet temperature, 0 pumping pipe (0 stage gas extraction pipe referred to as "0 pumping pipe") upper and lower wall temperature, No. 0 high gas inlet steam pressure, The thermal control measurement values of unit load and primary frequency modulation slip signal realize the heating pipe control, environmental protection control,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com