Digestion method of metallurgical materials and detection method

A material and alkali metal technology, applied in the field of digestion and detection of metallurgical materials, can solve problems such as vessel corrosion, achieve the effects of reduced dosage, wide application fields, and simple requirements for experimental equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

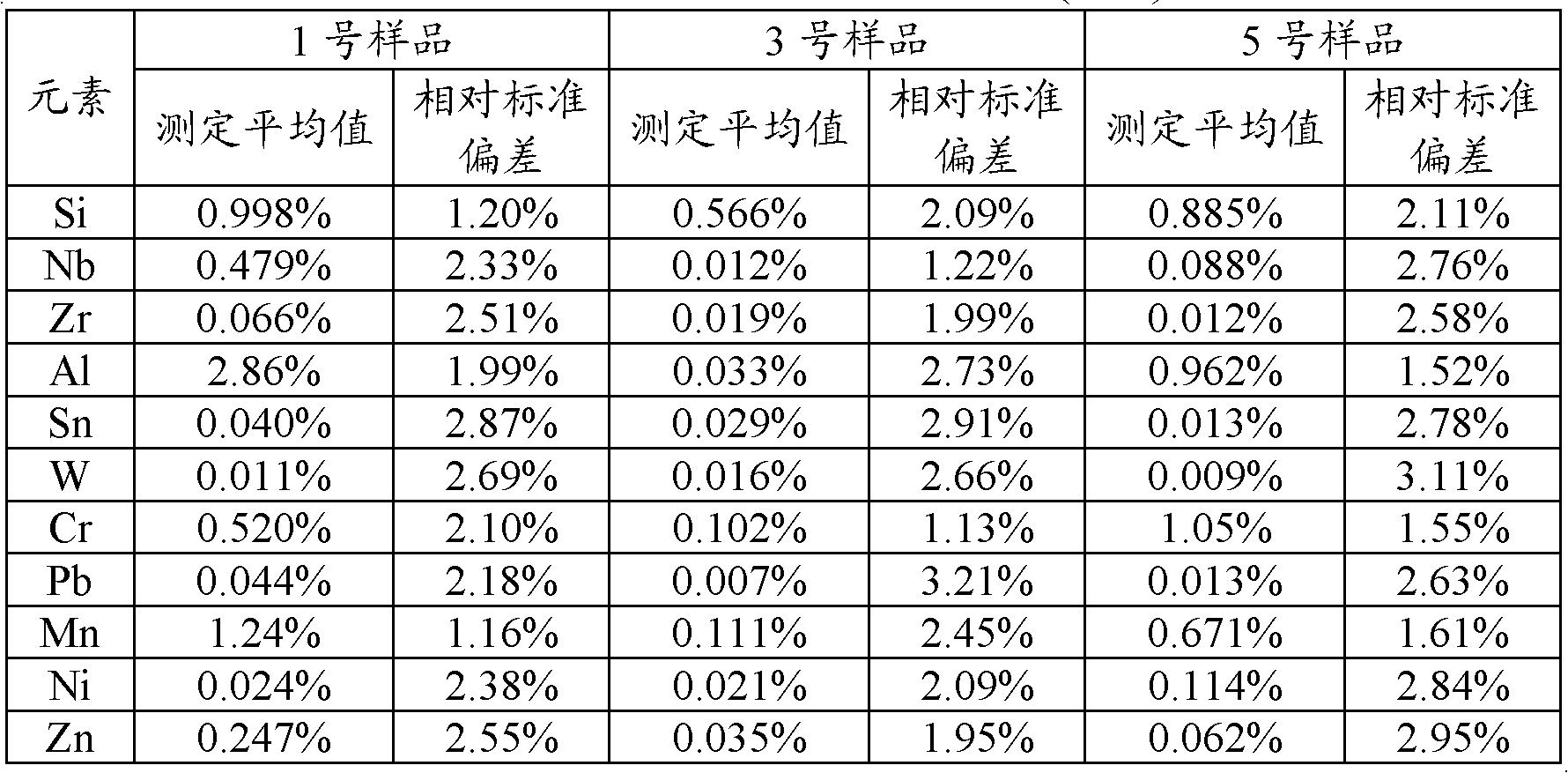

Embodiment 1

[0040] Digestion of titanium ore samples

[0041] Weigh 0.1 titanite sample (hereinafter referred to as No. 1 sample) and place it in a container, add 20 mL of hydrochloric acid solution for heating and digestion until the reaction is basically completed, and after the solution emits uniform large bubbles, filter it with slow filter paper while it is hot, and use 20 mL of 80 ℃ hot water, rinse the container and wash the residue several times a small amount, and collect the filtrate in a 200mL volumetric flask. Place the washed residue in a platinum crucible, heat it to 450°C in a muffle furnace to fully ash the residue, then take it out and cool it to room temperature; then add 0.1g of lithium tetraborate, and stir and mix well with the residue, re- Put it into a muffle furnace and melt it at 950°C for 20 minutes; after cooling, add 7mL of concentrated hydrochloric acid to boil for leaching, then combine with the above-mentioned collected filtrate and dilute to the original ...

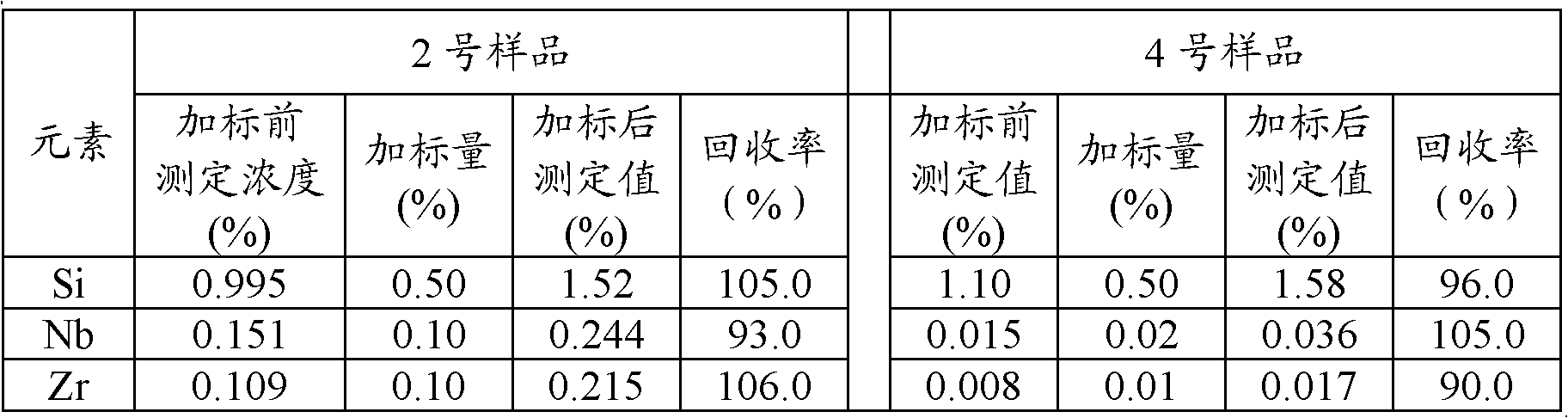

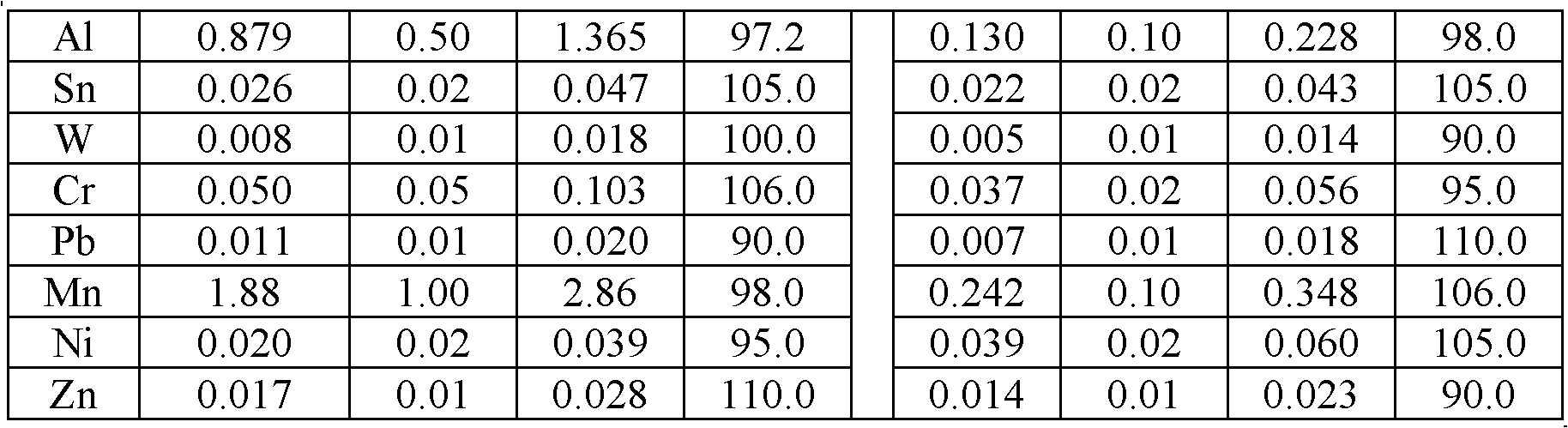

Embodiment 2

[0045] The metallurgical material sample containing refractory oxides to be digested according to Example 2 is a titanium slag sample. Take 0.3g sample (hereinafter referred to as sample No. 2) and digest it with 15mL of nitric acid, wash the residue with 15mL of 100°C hot water, collect the filtrate in a 100mL volumetric flask; incinerate the residue at 600°C, add 0.3g of sodium peroxide, and Melt at 800°C for 15 minutes, boil and extract with 8 mL of concentrated nitric acid, combine with the filtrate collected above, and dilute to volume with water. In addition, the titanium slag samples were digested and detected in the same manner as in Example 1.

Embodiment 3

[0047] The metallurgical material sample containing refractory oxides to be digested according to Example 3 is a ferro-titanium sample. Take 1.0g sample (hereinafter referred to as sample No. 3) and digest it with 15mL hydrochloric acid, wash the residue with 15mL hot water at 60°C, collect the filtrate in a 100mL volumetric flask; incinerate the residue at 250°C, add 0.5g lithium tetraborate, and Melt at 700°C for 25 minutes, boil and extract with 10mL of concentrated hydrochloric acid, combine with the filtrate collected above, and dilute to volume with water. In addition, the ferro-titanium sample was digested and detected according to the same method as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com