Method for detecting content of metal elements in polyether amine solid catalyst

A technology of metal element content and solid catalyst, which is applied in the detection field of metal element content in polyetheramine solid catalyst, can solve the problems of poor accuracy and stability, low sensitivity of detection method, long processing time, etc., and achieves precision and accuracy. The effect of high degree of precision, elimination of matrix interference and less reagent consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

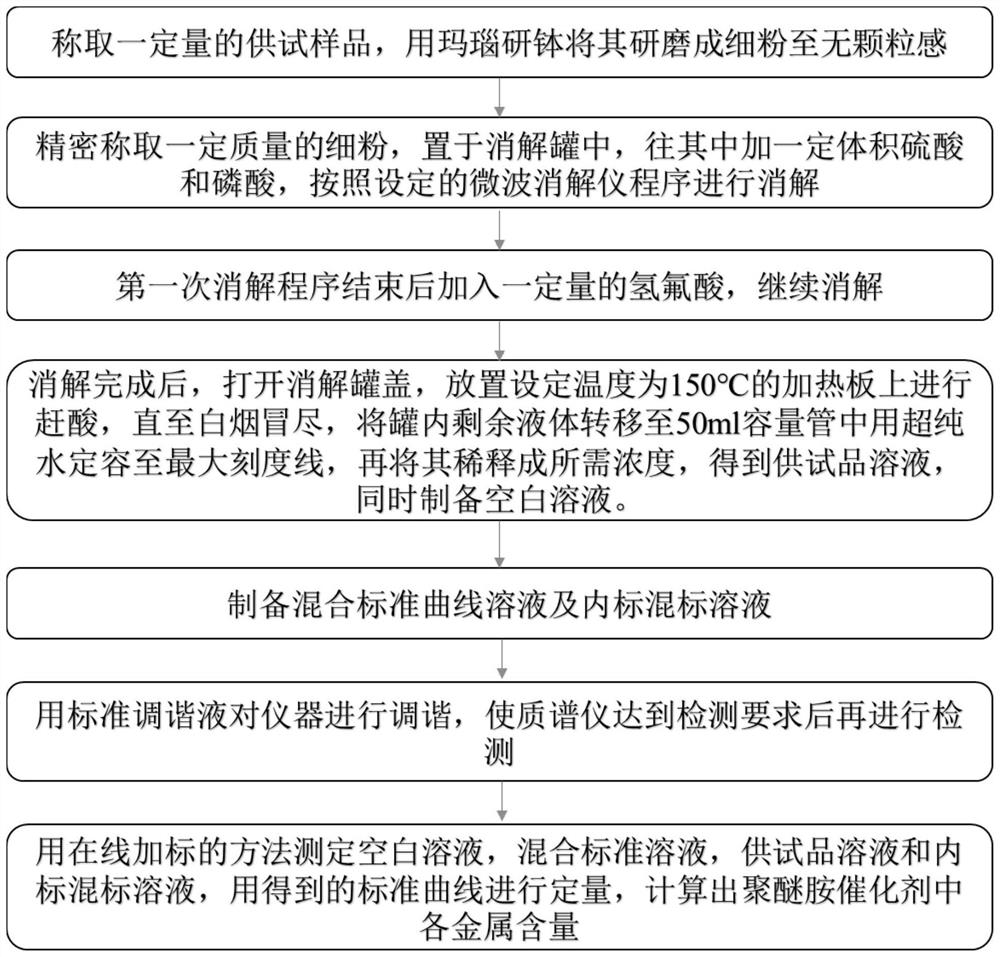

[0048] as Figure 1 As shown in the present embodiment, a polyetheramine solid catalyst in the detection method of metal element content, comprising the following steps:

[0049] (1) Preparation of test product solution: weigh a certain amount of polyetheramine solid catalyst for test sample, polyether amine solid catalyst for supported nickel catalyst, model is SNCAT-1800TE, with an agate mortar to grind the test sample into a fine powder, until ground to no particles. Precision weigh fine powder 0.2g, placed in the digestion tank, add sulfuric acid 9ml, phosphoric acid 6ml, cover the inner lid, placed in the microwave digester, in accordance with the set microwave digestion program for the first microwave digestion, after the digestion is completed, the digestion tank is cooled, and then add 2ml of hydrofluoric acid, placed in the microwave digester, in accordance with the microwave digestion program for the second microwave digestion, after the completion of the digestion placed...

Embodiment 2

[0084]The present embodiment of a polyetheramine solid catalyst in the detection method of metal element content, the difference with Example 1 is that step (1) to prepare the sample solution and blank solution when the amount of raw materials used is different, in the present embodiment of the sample solution preparation method is as follows:

[0085] Preparation of test solution: weigh a certain amount of polyetheramine solid catalyst for test sample, polyether amine solid catalyst for supported nickel catalyst, model is SNCAT-1800TE, with an agate mortar to grind the test sample into a fine powder, Precision weigh fine powder 0.3g, placed in the digestion tank, add sulfuric acid 10ml, phosphoric acid 7ml, cover the inner lid, placed in the microwave digester, in accordance with the set microwave digestion program for digestion, after the digestion is completed, the digestion tank is cooled, and then add 4ml of hydrofluoric acid, placed in the microwave digester, in accordance w...

Embodiment 3

[0090] The present embodiment of a polyetheramine solid catalyst in the detection method of metal element content, and the difference between Example 1 is only that step (1) to prepare the sample solution and the blank solution used in the amount of raw materials used is different, in the present embodiment of the sample solution preparation method is as follows:

[0091]Preparation of test solution: weigh a certain amount of polyetheramine solid catalyst for test sample, polyether amine solid catalyst for supported nickel catalyst, model is SNCAT-1800TE, with an agate mortar to grind the test sample into a fine powder, Precision weigh fine powder 0.4g, placed in the digestion tank, add sulfuric acid 20ml, phosphoric acid 10ml, cover the inner lid, placed in the microwave digester, in accordance with the set microwave digestion program for digestion, after the digestion is completed, the digestion tank is cooled, and then add 4ml of hydrofluoric acid, placed in the microwave diges...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com