Voltage automatic calibration device

An automatic calibration and voltage calibration technology, which is applied in the direction of measuring devices, measuring electrical variables, instruments, etc., can solve the problems of discrete differences in battery voltage, cumbersome steps, and dependence on manual operations, so as to overcome fluctuations and discrete differences and improve voltage sampling accuracy , to avoid the effect of human error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

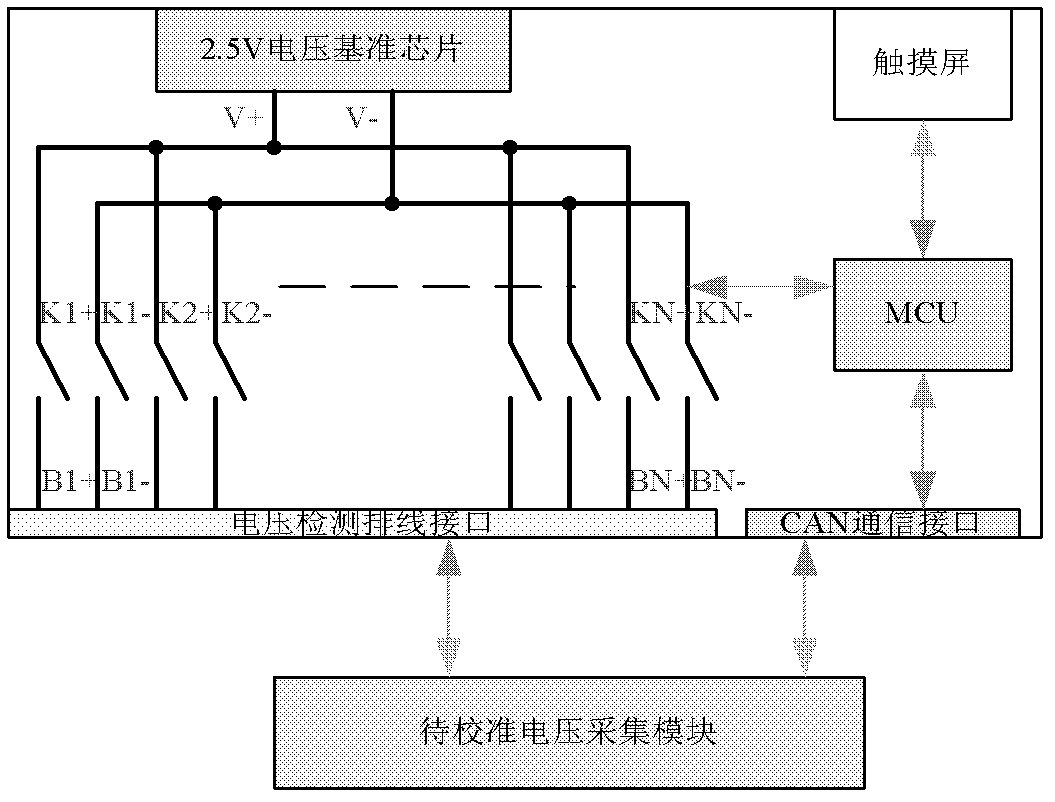

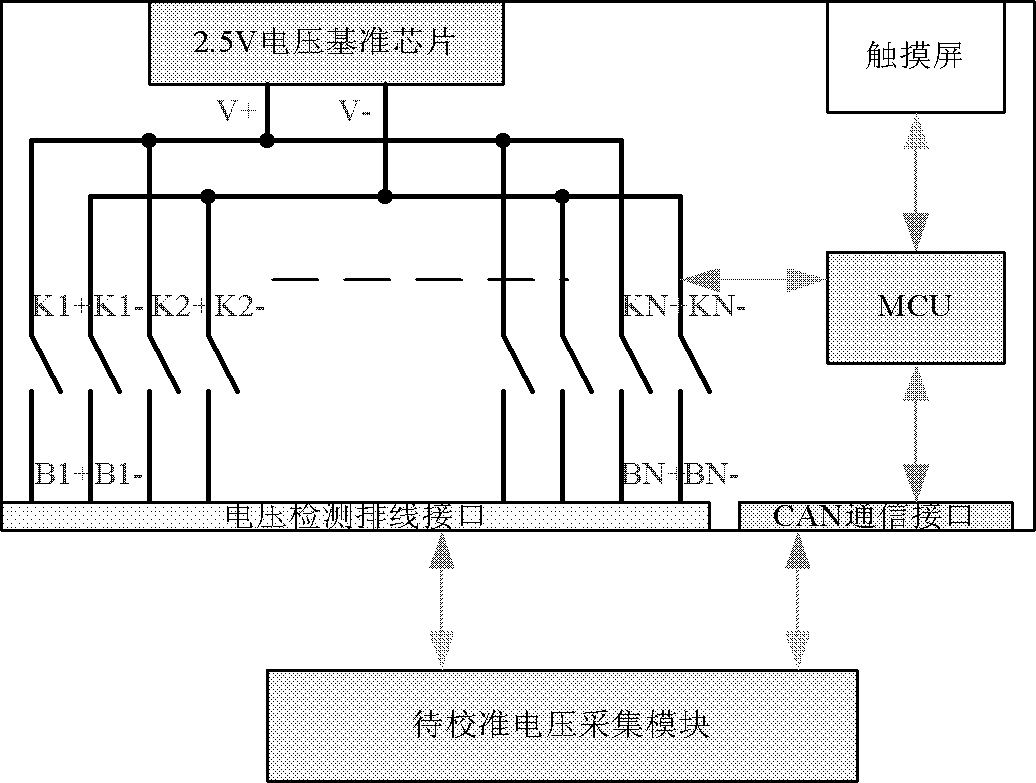

[0015] See figure 1 , A voltage automatic calibration device, including a high-precision voltage reference source, a multi-channel switching relay, a voltage acquisition module and a single-chip control unit. The high-precision voltage reference source is composed of a 2.5V voltage stabilizer chip and its peripheral circuits. The nominal accuracy of the output voltage of the reference source is 1mV, and it has a temperature compensation function. In addition, the voltage drift within 5°C is negligible. One end of each channel switching relay is connected to a high-precision voltage reference source, and each channel switching relay The other end is connected to each voltage acquisition channel of the voltage acquisition module. The single-chip control unit is connected to the control end of each channel switching relay. The single-chip control unit controls the switching of the multi-channel switching relay. The single-chip control unit collects the voltage through the CAN bus. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com