Tunable negative elastic modulus acoustic metamaterial

An acoustic metamaterial, elastic modulus technology, applied in the field of acoustic metamaterials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

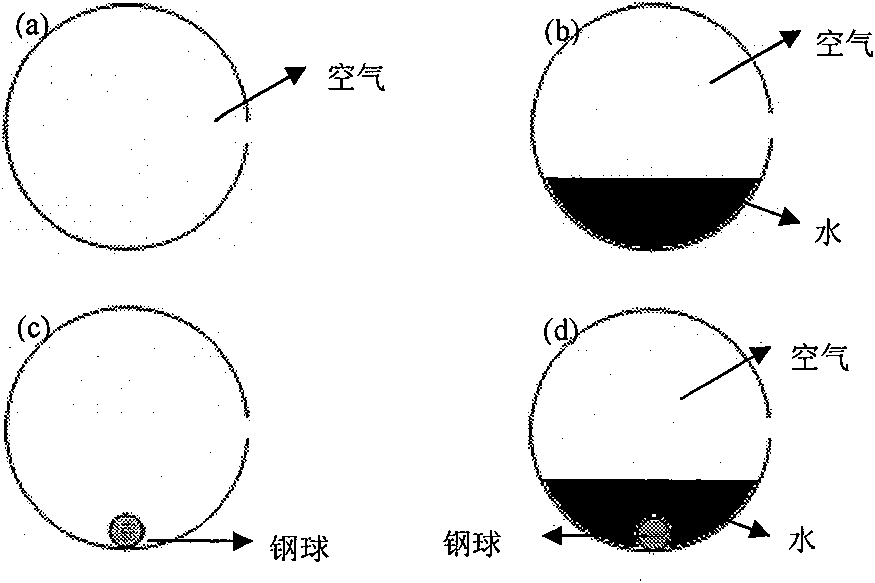

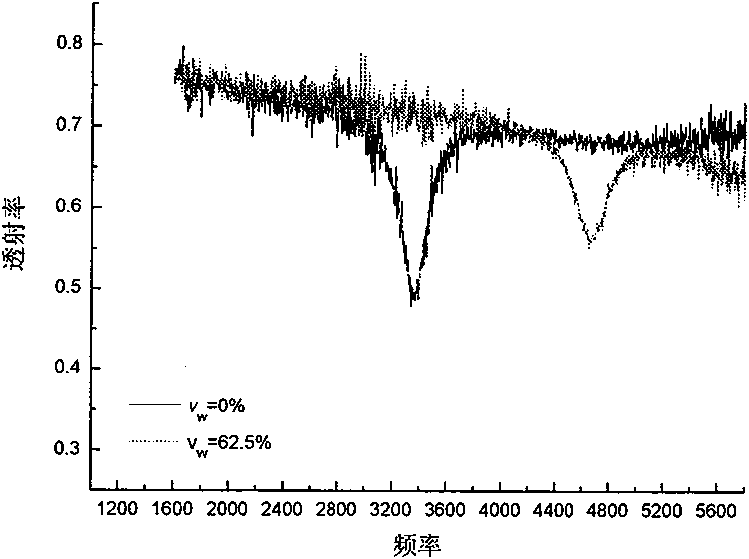

[0013] First: use mechanical drilling technology to drill a hole with a diameter of 2.5mm on one side of a polystyrene plastic hollow ball with a diameter of 10mm and a wall thickness of 0.5mm; secondly: prepare a sponge with a diameter of 30mm and a thickness of 25mm as a substrate; finally: put The prepared open hollow sphere is placed in the center of the sponge substrate, thus the SHS acoustic metamaterial is prepared, as figure 1 shown. In addition, the internal medium of the open hollow sphere see figure 2 (a), the water content is 0 vol%. The acoustic transmission curve of this metamaterial is as follows image 3 shown.

Embodiment 2

[0015] First: use mechanical drilling technology to drill a hole with a diameter of 2.5mm on one side of a polystyrene plastic hollow ball with a diameter of 10mm and a wall thickness of 0.5mm; secondly: prepare a sponge with a diameter of 30mm and a thickness of 25mm as a substrate; finally: put The prepared open hollow sphere is placed in the center of the sponge substrate, thus the SHS acoustic metamaterial is prepared, as figure 1 shown. In addition, the internal medium of the open hollow sphere see figure 2 (b), the content of water is 62.5vol%. The acoustic transmission curve of this metamaterial is as follows image 3 shown.

Embodiment 3

[0017] First: use mechanical drilling technology to drill a hole with a diameter of 4mm on one side of a polystyrene plastic hollow ball with a diameter of 10mm and a wall thickness of 0.5mm; secondly: prepare a sponge with a diameter of 30mm and a thickness of 25mm as a substrate; finally: prepare The open hollow sphere is placed in the center of the sponge substrate, thus the SHS acoustic metamaterial is prepared, just as figure 1 shown. In addition, the internal medium of the open hollow sphere see figure 2 (a), the water content is 0 vol%. The acoustic transmission curve of this metamaterial is as follows Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com