Etching liquid replenishing device, etching liquid replenishing method and wet etching equipment with etching liquid replenishing device

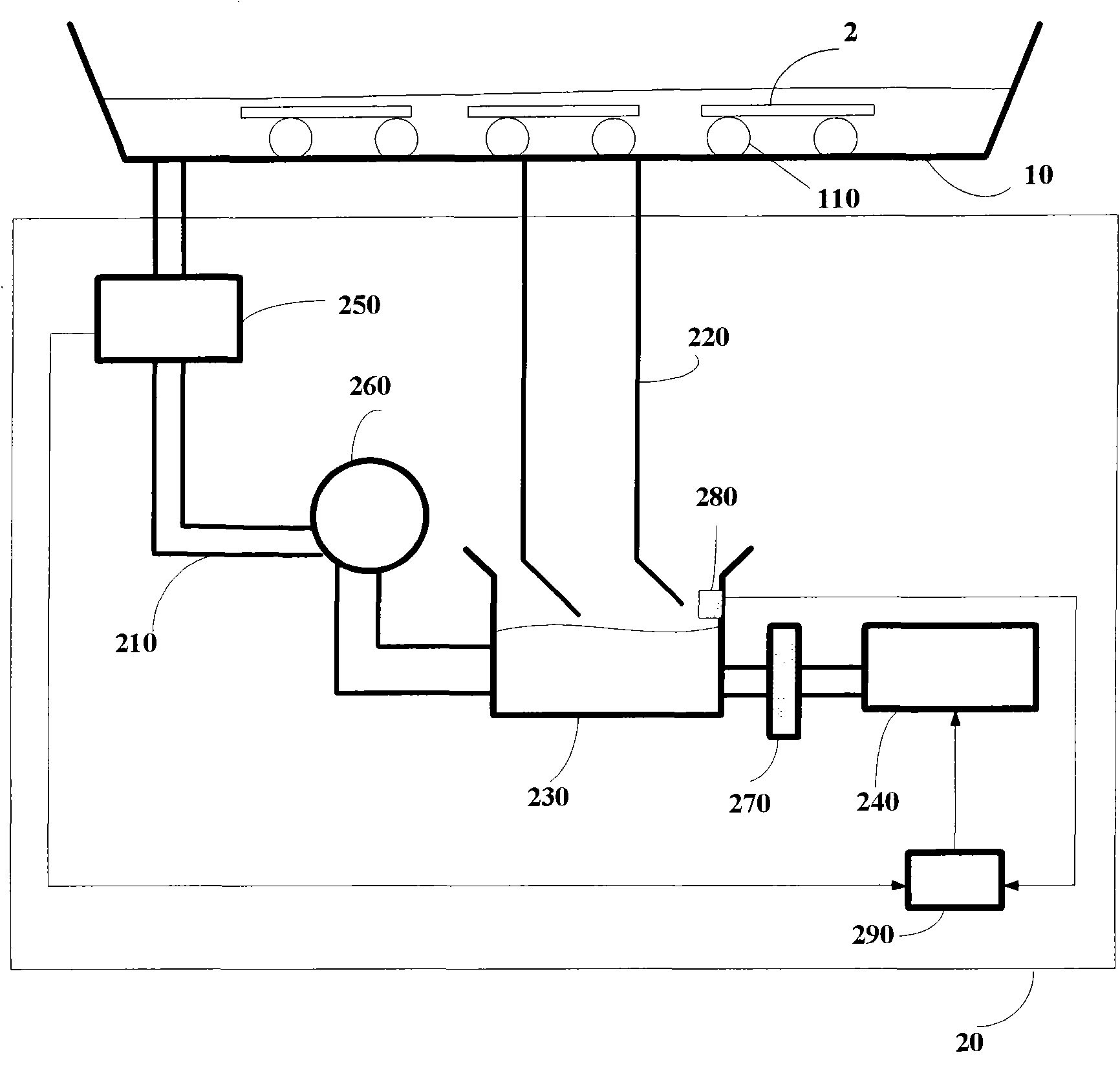

A wet etching and etching solution technology, which is used in semiconductor/solid-state device testing/measurement, electrical components, circuits, etc., can solve the problem of ineffective edge wet etching, etching solution failure, and concentration ratio difference. It can ensure the stability, reduce the harm and prolong the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

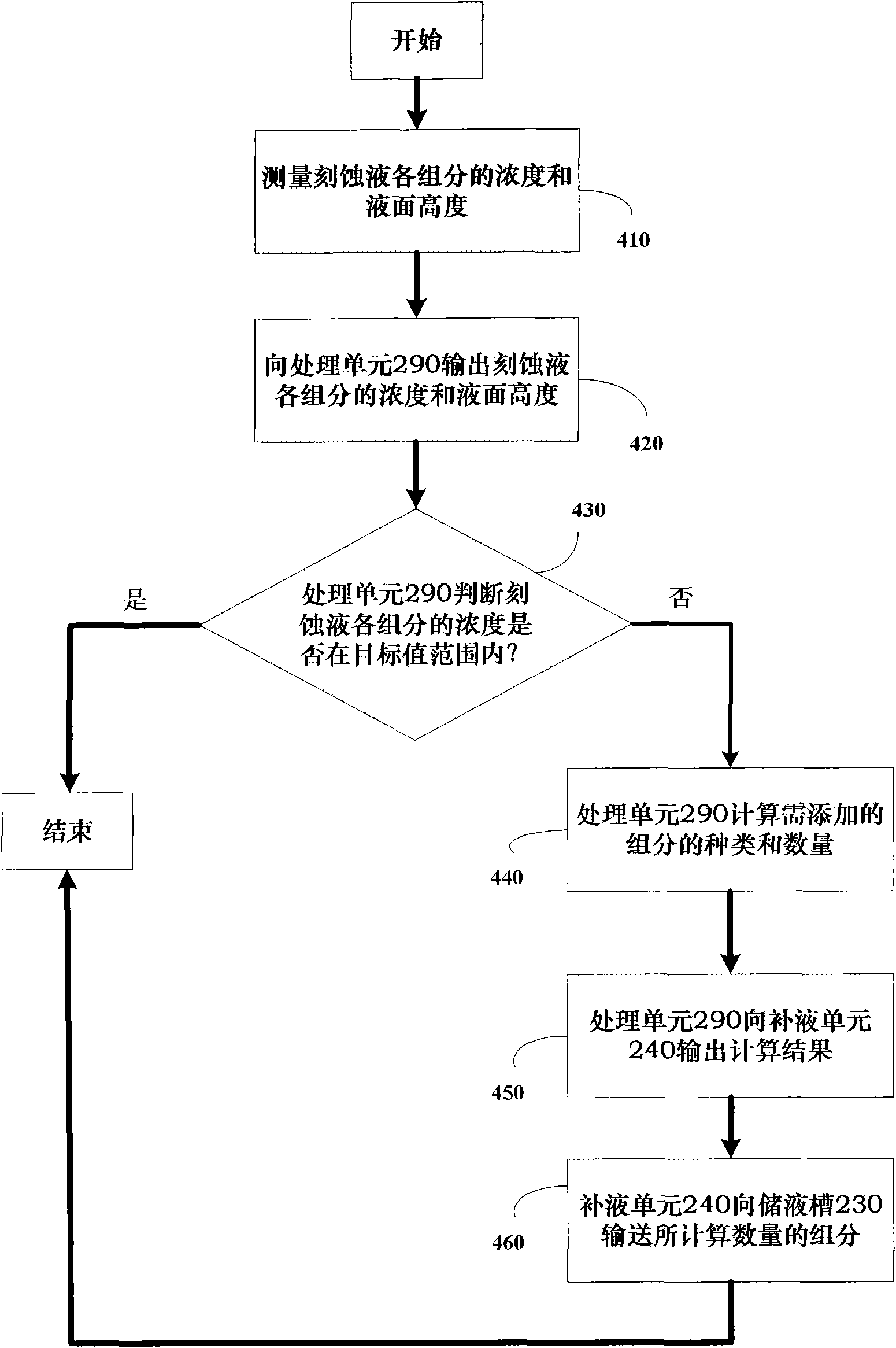

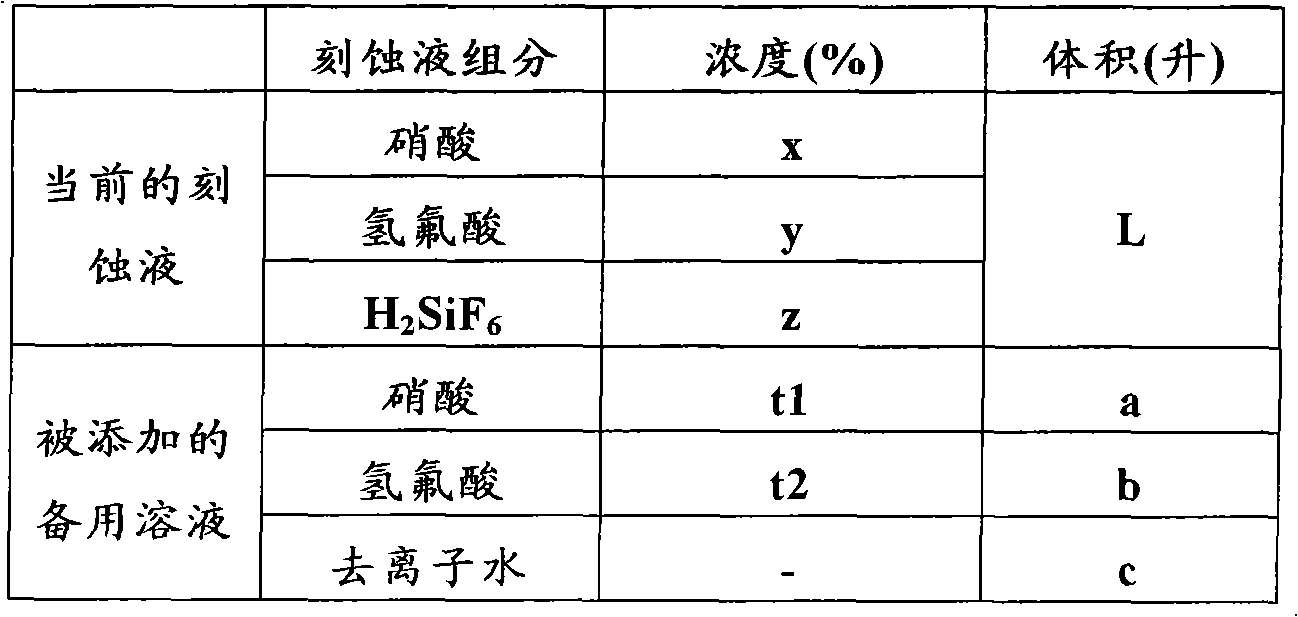

[0062] Nitric acid, hydrofluoric acid and H detected by the concentration detection unit 250 in step 410 2 SiF 6 The concentration of the etching solution is 37.9%, 5.5% and 0.5%, respectively, and the liquid level of the etching solution detected by the liquid level unit 280 in step 410 corresponds to the volume of the etching solution in the storage tank 230 being 20 liters. Processing unit 290 judges hydrofluoric acid and H 2 SiF 6 The concentration of the concentration is all within the target value range, so the above formula (1) will be used to calculate the amount of nitric acid with a concentration of 50% that needs to be added to be 4.2 liters according to the concentration of each component measured and the volume of the etching solution. After adding the above amount of nitric acid, the concentration of the hydrofluoric acid component became 4.55%, still within the target value range, while the H 2 SiF 6 The concentration is still lower than 1%, it can be seen t...

example 2

[0064] Nitric acid, hydrofluoric acid and H detected by the concentration detection unit 250 in step 410 2 SiF 6 The concentration of the etching solution is 41%, 3.9% and 0.8%, respectively, and the liquid level of the etching solution detected by the liquid level unit 280 in step 410 corresponds to the volume of the etching solution in the liquid storage tank 230 being 30 liters. The processing unit 290 judges H 2 SiF 6 The concentration is within the target value range, but the concentrations of nitric acid and hydrofluoric acid have deviated from their respective target value ranges, so the above formulas (1) and (2) will be used, according to the measured concentration of each component and the etching According to the volume of liquid, it is calculated that the nitric acid quantity of 50% concentration that needs to be added is 11.4 liters, and the hydrofluoric acid quantity of 30% concentration that needs to be added is 3.6 liters. After adding the above amounts of n...

example 3

[0066] Nitric acid, hydrofluoric acid and H detected by the concentration detection unit 250 in step 410 2 SiF 6 The concentration of the etching solution is 40%, 5% and 1.1%, respectively, and the liquid level of the etching solution detected by the liquid level unit 280 in step 410 corresponds to the volume of the etching solution in the liquid storage tank 230 being 20 liters. The processing unit 290 judges H 2 SiF 6 The concentration deviates from the target value range, and the concentrations of nitric acid and hydrofluoric acid are within their respective target value ranges, so the above formulas (1)-(3) will be used, according to the measured concentration of each component and the volume of the etching solution , Calculate the amount of nitric acid with a concentration of 50% that needs to be added to be 12 liters, the amount of hydrofluoric acid with a concentration of 30% that needs to be added is 2.5 liters, and the amount of deionized water that needs to be adde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com