Processing method of photovoltaic glass synthesizer

A photovoltaic glass and processing method technology, applied in sustainable manufacturing/processing, semiconductor devices, electrical components, etc., to achieve the effect of improving efficacy, saving energy, and ensuring processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

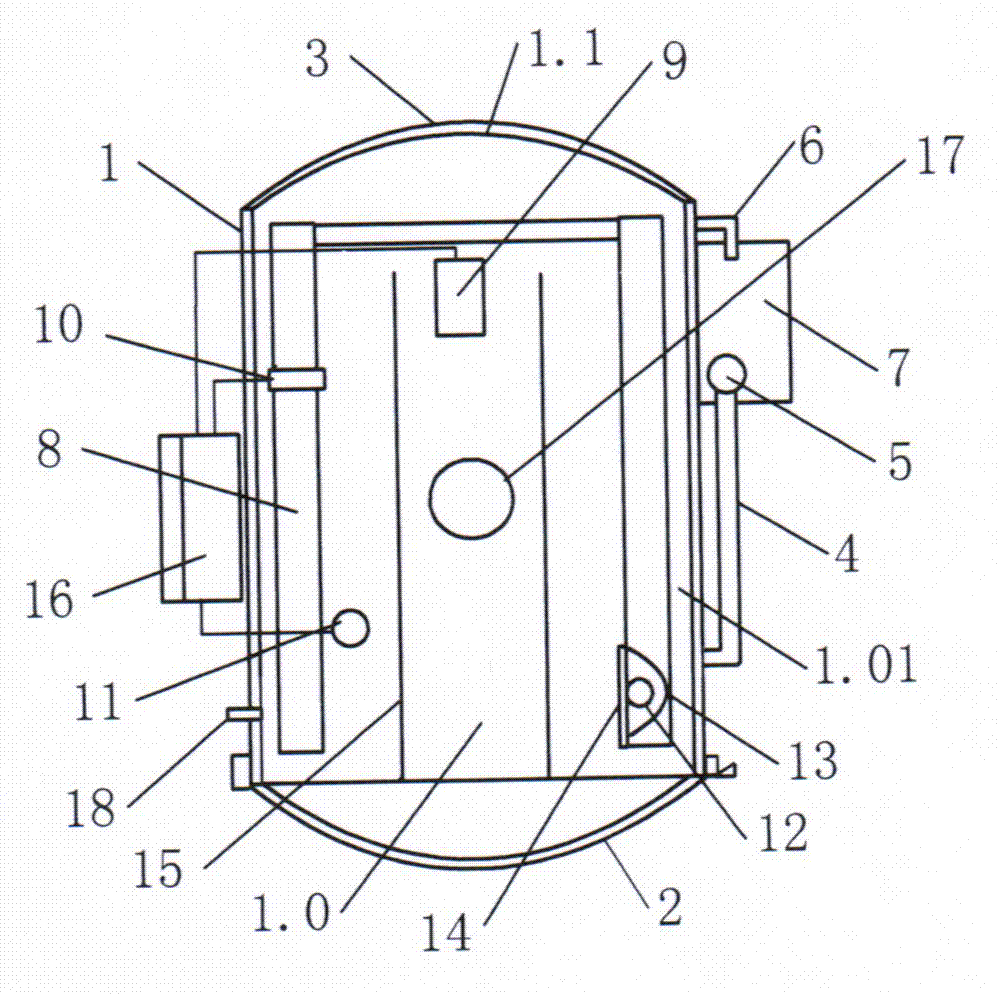

[0009] According to the picture:

[0010] The synthesizer 1 is a cylindrical structure, with a head 3 at one end, a door 2 at the other end, and an inner cavity 1.0;

[0011] One side of the synthesizer is provided with a console 16, on which a temperature controller, a pressure controller and an image display are installed;

[0012] The other side of the synthesizer is provided with a cooling water tank 7;

[0013] One or more electromagnetic fans 17 are installed on the synthesizer;

[0014] The synthesizer is provided with a water supply pipe 4 and a water outlet pipe 6, and the end of the water supply pipe is connected with a water supply pump 5, and the water supply pump is placed in the cooling water tank; the water supply pipe and the water outlet pipe are used in the water circulation cooling of the vertical pipe and the horizontal pipe Cavity;

[0015] An air injection pipe 18 is arranged between the outer wall of the synthesizer and the inner cavity, and is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com