Alignment method for preparing membrane electrode sealing border of fuel cell

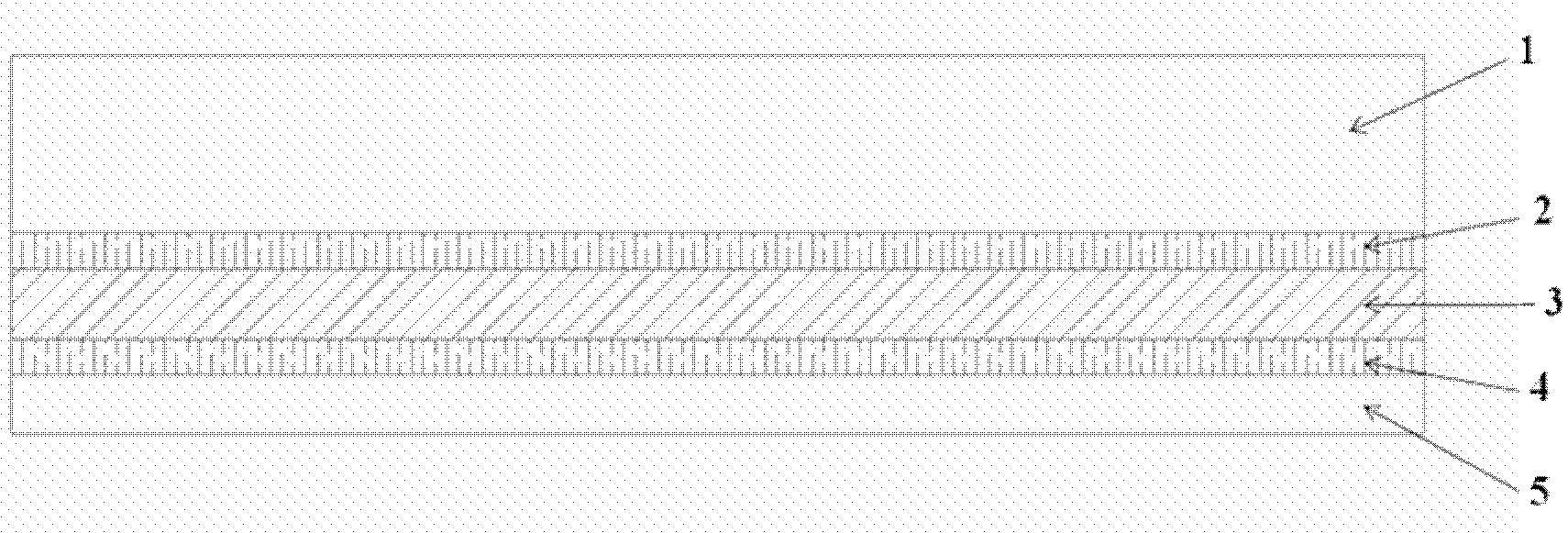

A fuel cell membrane and sealing edge technology, which is applied to fuel cell components, fuel cells, circuits, etc., can solve problems such as explosion, fuel cell failure, and influence on membrane electrode processing, and achieve the effect of being easy to distinguish from each other

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] In this embodiment, the alignment target accuracy is: the alignment deviation of the cathode and anode active areas is not greater than 0.20 mm.

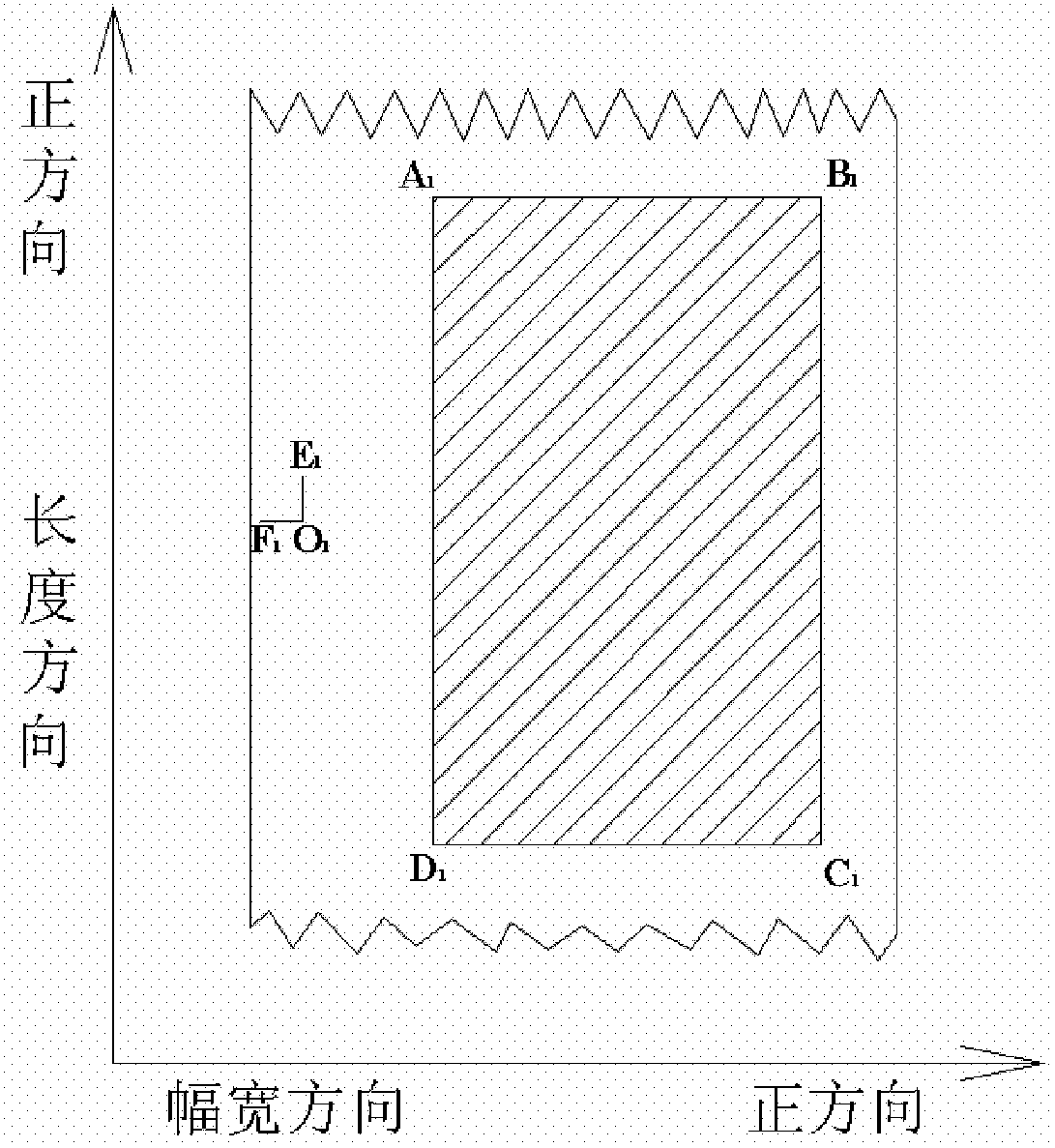

[0073] 1) Laminate the frames with a width of 170mm, and cut the active area A of the cathode sealing frame according to the position shown in Figure 2(a) 1 B 1 C 1 D. 1 , A 1 B 1 C 1 D. 1 is a rectangle, A 1 D. 1 Parallel to the length of the border overlay. A 1 B 1 =C 1 D. 1 =120mm, A 1 D. 1 =B 1 C 1 =200mm.

[0074] 2) While punching the active area of the cathode sealing frame, punch and apply the cathode alignment mark E on the support film of the cathode frame laminate in the direction of the frame film at the position shown in Figure 2(a) 1 o 1 f 1 , where E 1 o 1 ⊥F 1 o 1 ,E 1 o 1 / / A 1 D. 1 ,E 1 o 1 =F 1 o 1 = 4mm, O 1 to A 1 D. 1 The distance is 20.00mm, O 1 to A 1 B 1 The distance is 60.00mm. E. 1 o 1 , F 1 o 1 The punching depth does not exceed the thickness of the supp...

Embodiment 2

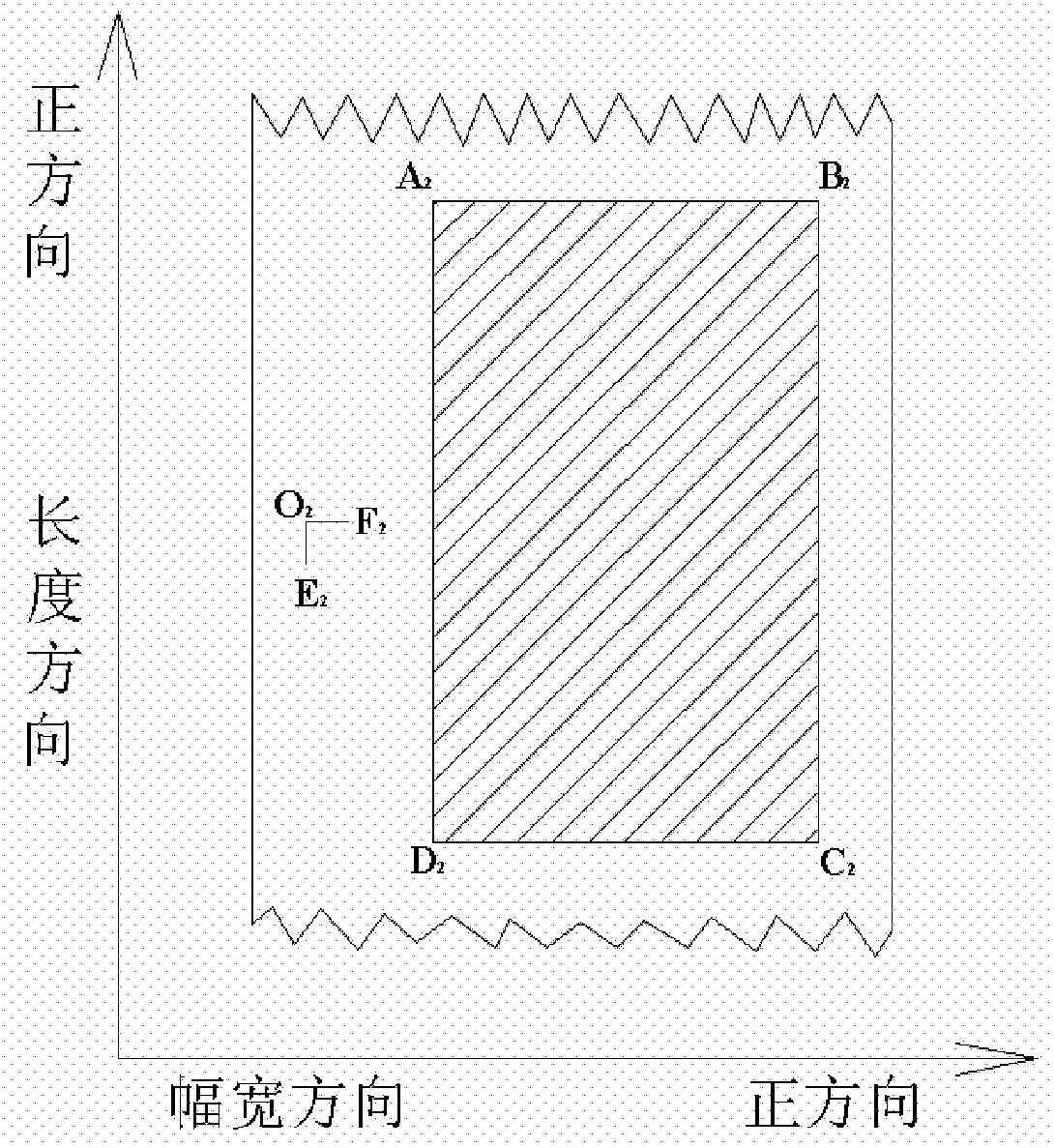

[0083] In this embodiment, the alignment target accuracy is: the alignment deviation of the cathode and anode active areas is not greater than 0.20 mm.

[0084] 1) if Figure 6 As shown, the frame with a width of 170mm is laminated M, and the active area of the cathode sealing frame is punched out a 1 , b 1 、c 1 … g 1 、h 1 i 1 , a 1 , b 1 、c 1 … g 1 、h 1 i 1 They are all rectangles of 200mm×120mm, where the length direction is 200mm and the width direction is 120mm. Each rectangular active area is 20mm away from the positive edge of the frame laminate material in the width direction, and 30mm from each rectangular active area to the negative edge of the frame laminate material in the width direction, and the distance between each rectangular active area is equal. While punching the active area, the cathode alignment marks are simultaneously punched on the edge of the frame laminated support film, and the positions of each cathode alignment mark are fixed and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com