Polypropylene resin, polypropylene resin composition, and foam-injection-molded article

A technique of polypropylene-based, injection-molded foaming, applied in the field of polypropylene-based resins, polypropylene-based resin compositions, and injection-molded foamed moldings, capable of solving the physical properties of molded objects (reduced impact resistance, insufficient, unsuitable for injection molding) Foam molding and other problems, to achieve excellent fluidity and foamability, less silver streaks and flow marks, and good surface appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0116]

[0117] 100 parts by weight of a propylene homopolymer (manufactured by Prime Polymer Co., Ltd., J108M) having a melt flow rate of 45 g / 10 minutes as a linear polypropylene-based resin and peroxyisopropyl carbonic acid as a radical polymerization initiator The mixture of 1.0 parts by weight of tert-butyl ester was supplied to a twin-screw extruder (L / D=40) of 45 mmΦ from a hopper at a rate of 70 kg / hour, melted and kneaded at a barrel temperature of 200 ° C, and was set in the middle using a quantitative pump. 0.3 parts by weight (speed of 0.21 kg / hour) of isoprene monomer as a conjugated diene compound was supplied in the press-in part of the above-mentioned twin-screw extruder for melt-kneading to obtain modified polypropylene Resin-like particles.

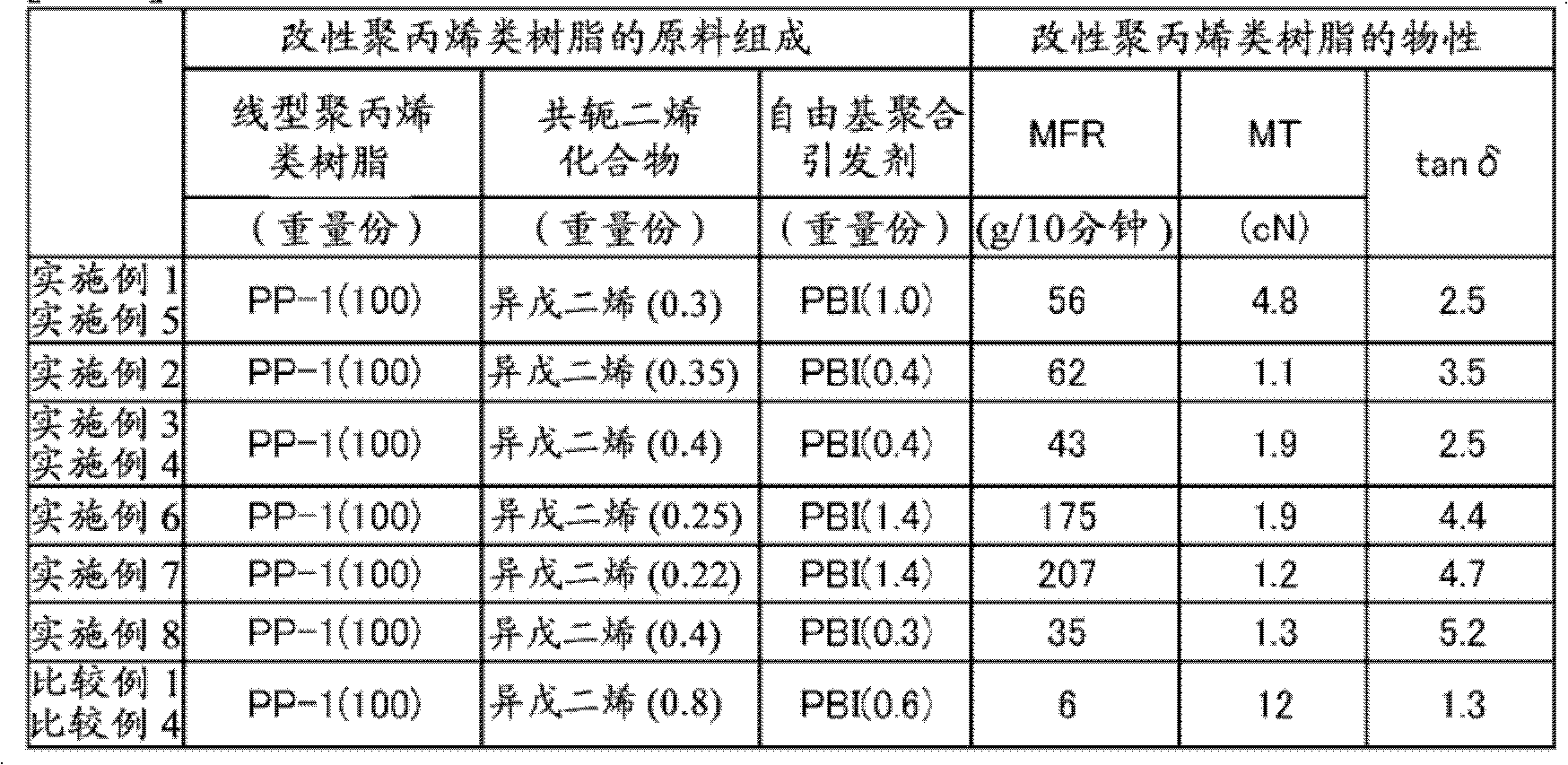

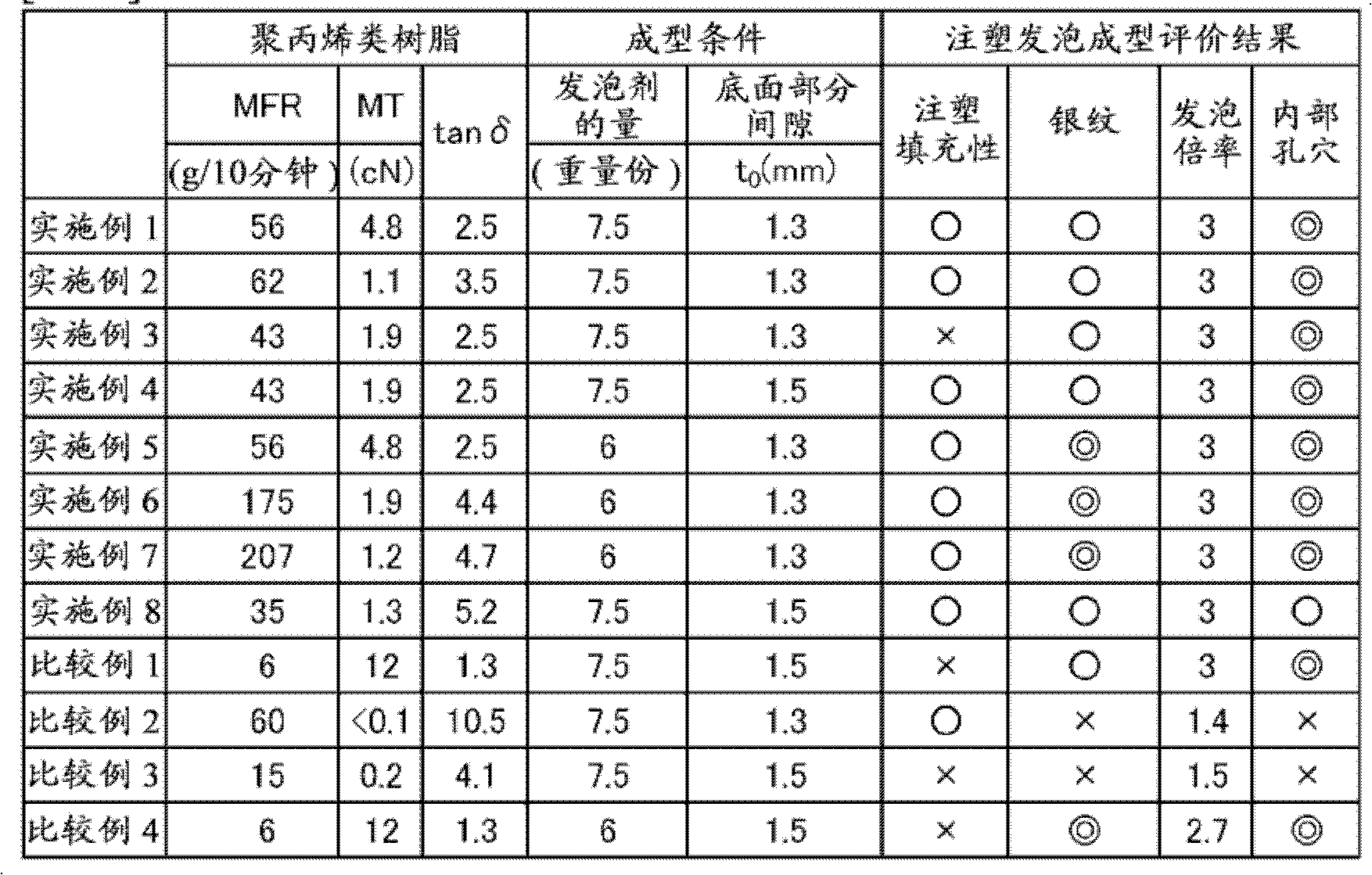

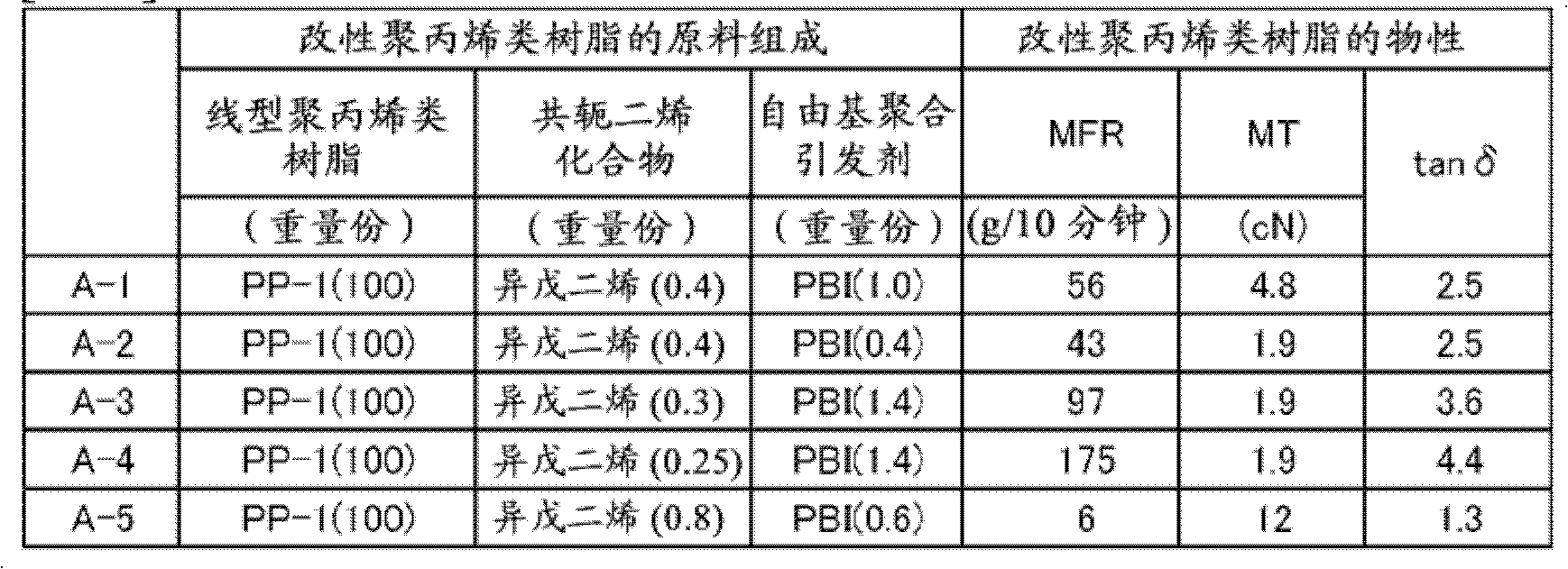

[0118] The evaluation of the obtained modified polypropylene-based resin is shown in Table 1.

[0119]

[0120] To 100 parts by weight of the obtained modified polypropylene-based resin, 7.5 parts by weight of a sod...

Embodiment 2

[0123]

[0124] The same operation as in Example 1 was carried out except that the mixing amount of tert-butyl peroxyisopropyl carbonate was changed to 0.4 parts by weight, and the supply amount of isoprene was changed to 0.35 parts by weight to obtain a modified polymer. acrylic resin.

[0125]

[0126] Injection foaming was performed in the same manner as in Example 1 to obtain an injection foamed molded body.

[0127] The evaluation of the obtained modified polypropylene-based resin is shown in Table 1, and the evaluation of the injection-foamed molded product is shown in Table 2.

Embodiment 3

[0129]

[0130] The same operation as in Example 1 was carried out, except that the mixing amount of tert-butyl peroxyisopropyl carbonate was changed to 0.4 parts by weight, and the supply amount of isoprene was changed to 0.4 parts by weight to obtain a modified polymer. acrylic resin.

[0131]

[0132] Injection foaming was performed in the same manner as in Example 1 to obtain an injection foamed molded body.

[0133] The evaluation of the obtained modified polypropylene-based resin is shown in Table 1, and the evaluation of the injection-foamed molded product is shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| tension | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com