Infrared-reflective paint and infrared-reflective resin composition

A technology of reflective resin and infrared rays, which is applied in the field of infrared reflective coatings and infrared reflective resin compositions, which can solve problems such as difficulty in maintaining tactility or appearance, and thermal deterioration of leather products, and achieve the effect of maintaining tactility or appearance and suppressing the rise in surface temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

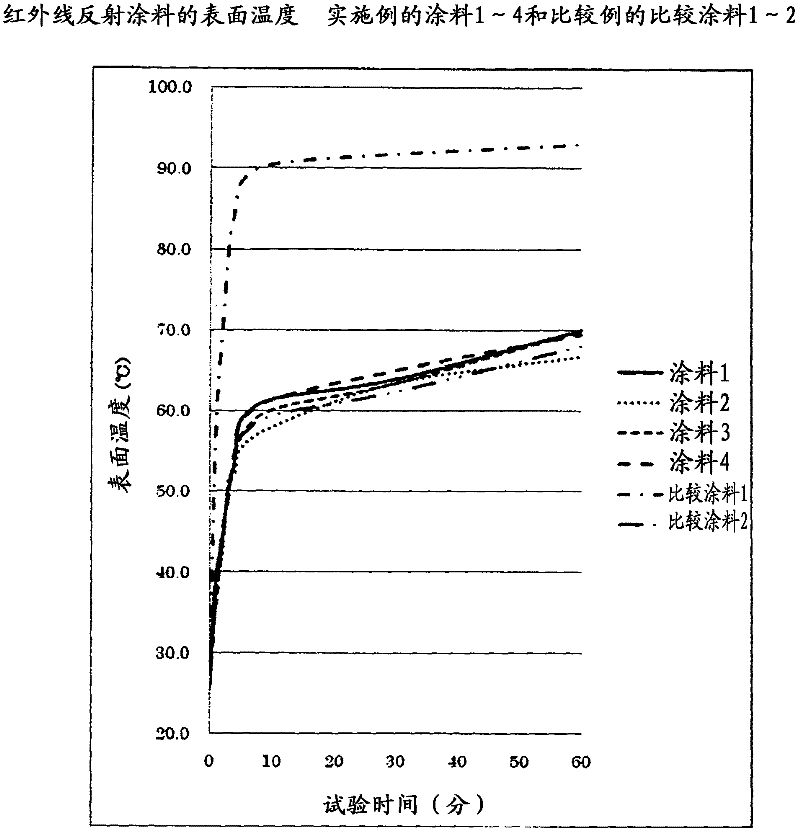

[0077] (Coatings for natural leather and artificial leather with infrared reflection function)

[0078] The coating material for natural leather and artificial leather having an infrared ray reflecting function of the present invention was produced using the following components.

[0079]

[0080] Polyurethane resin: Binda-RB

[0081] (Solid content of Emeraldine resin manufactured by Gosho Sangyo Co., Ltd. 30%)

[0082]Glass transition temperature: about 10°C

[0083] Acrylic resin A: Binder-SA

[0084] (Goshang Sangyo Co., Ltd. Emalujin resin solid content 30%)

[0085] Glass transition temperature: about -10°C

[0086] Nitrocellulose varnish: Dragria

[0087] (Solid content of nitrocellulose resin solution manufactured by Gosang Sangyo Co., Ltd. 13%)

[0088] Glass transition temperature: above 100°C

[0089]

[0090]

[0091]

[0092] The average particle size of the red reflective pigme...

Embodiment 2

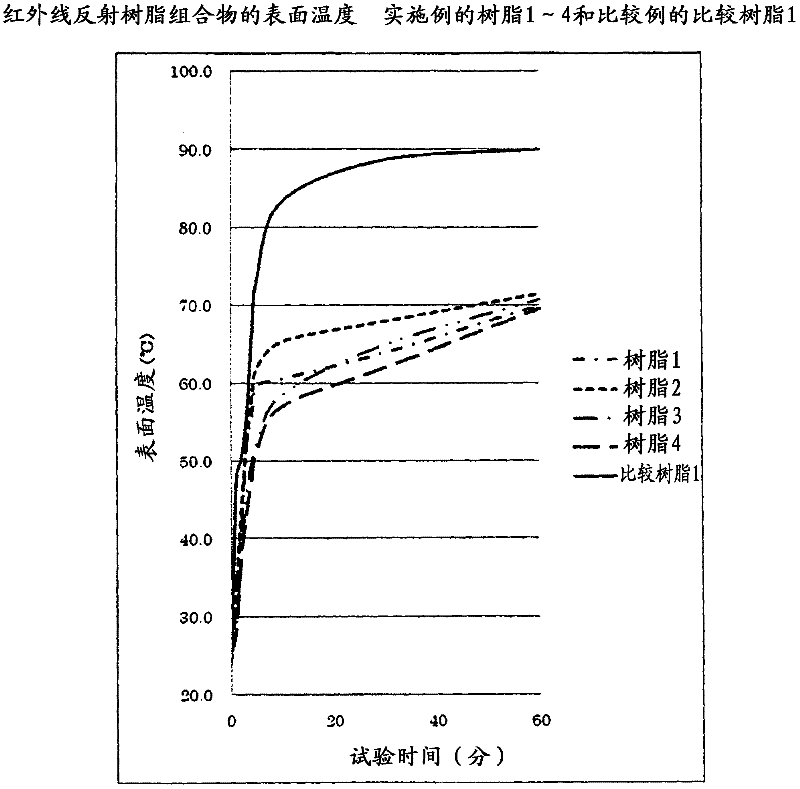

[0105] (Infrared reflective resin composition having infrared reflective function)

[0106] The infrared reflective resin composition having an infrared reflective function of the present invention was produced using the following components.

[0107]

[0108] ABS resin: TM30 (manufactured by ユエエムジー・エビビゴェス)

[0109] Polypropylene resin: Nobatec MA3 (manufactured by Japan Polypro)

[0110] Acrylic resin B: Delbett 60N (manufactured by Asahi Kasei Chemicals)

[0111] Vinyl chloride resin: MT1100 (manufactured by Vitec)

[0112]

[0113]

[0114] The average particle diameter of the red reflective pigment used and the value of the reflectance peak at a wavelength of 750 nm to 2600 nm are shown in Table 3 below.

[0115] [table 3]

[0116] The average particle size

Infrared reflective black pigment A

0.7μm

60% (1500nm)

Infrared reflective black pigment B

0.3μm

60% (1500nm)

Inorganic White Pigment

-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com