Artificial leather with cold air permeability, and preparation method and application thereof

A technology of artificial leather and air permeability, applied in the field of automobile interior materials, can solve the problems of obvious surface heating, undisclosed artificial leather materials, waste of energy and time, etc., and achieve the effect of simple process, good ventilation and ventilation effect, and ensuring comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

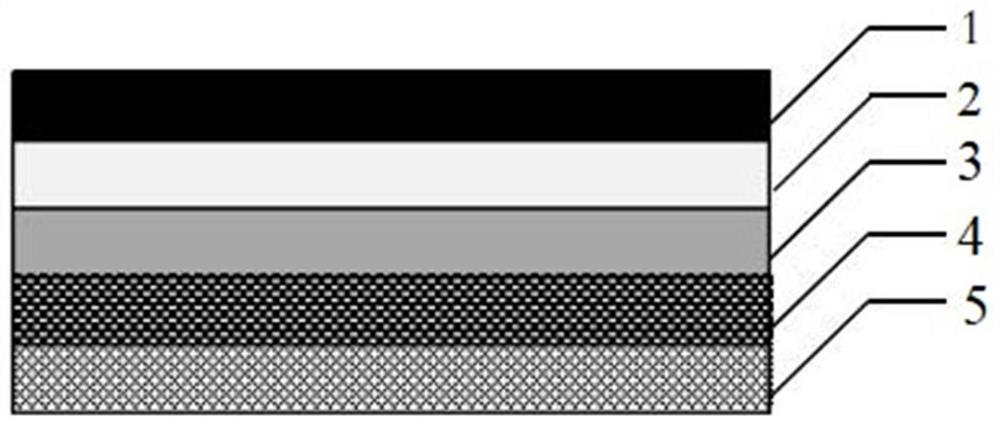

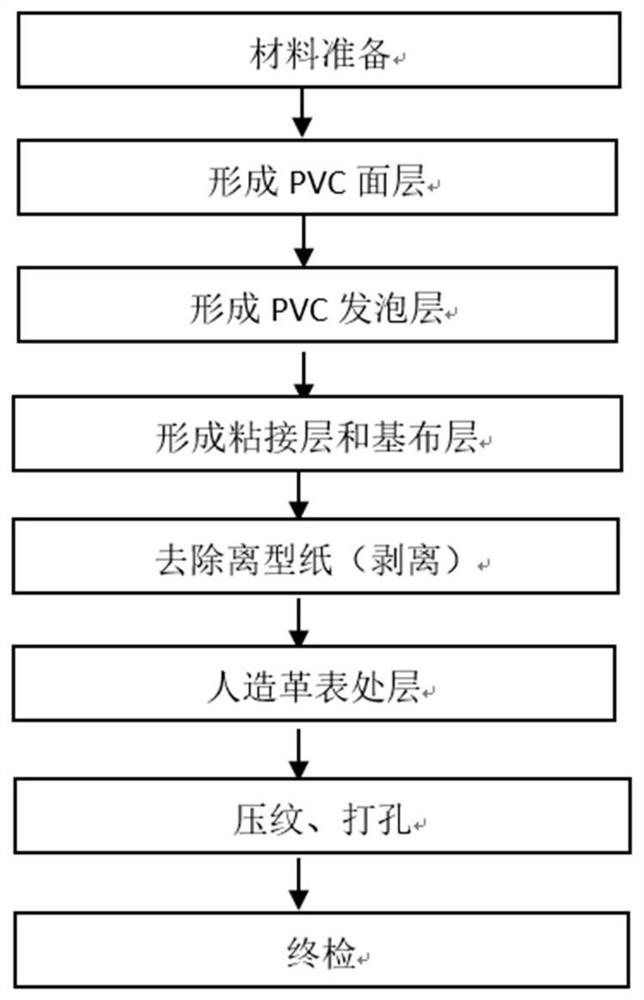

[0079] This embodiment discloses a method for preparing an artificial leather with cold air permeability. The artificial leather is composed of a base fabric layer, a PVC adhesive layer, a PVC foam layer, a PVC dense layer and a surface layer from bottom to top.

[0080] The PVC dense layer is made up of the following raw materials in parts by mass:

[0081] Polyvinyl chloride: 100 parts, its K value is 65, plasticizer: 50 parts, described plasticizer is the mixture of DPHP and DOA, infrared reflection aid: 4 parts, stabilizer: 1 part, it is specifically calcium Zinc stabilizer, color paste: 2 parts;

[0082] Mix the components of the above formula and stir for 10 to 15 minutes → three-roller grinding → vacuumize and stir for 40 minutes, control the viscosity: 3000 ~ 12000cps → filter to obtain a polyvinyl chloride dense layer slurry;

[0083] Described PVC foam layer is made up of each raw material of following mass parts:

[0084] Polyvinyl chloride: 100 parts, its K value...

Embodiment 2

[0103] This embodiment discloses a method for preparing an artificial leather with cold air permeability. The artificial leather is composed of a base fabric layer, a PVC adhesive layer, a PVC foam layer, a PVC dense layer and a surface layer from bottom to top.

[0104] The PVC dense layer is made up of the following raw materials in parts by mass:

[0105] Polyvinyl chloride: 100 parts, its K value is 80, plasticizer: 70 parts, described plasticizer is the mixture of DPHP and DOA, infrared reflection auxiliary agent: 14 parts, stabilizer: 7 parts, it is specifically calcium Zinc stabilizer, color paste: 8 parts;

[0106] Mix the components of the above formula and stir for 10 to 15 minutes → three-roller grinding → vacuumize and stir for 40 minutes, control the viscosity: 3000 ~ 12000cps → filter to obtain a polyvinyl chloride dense layer slurry;

[0107] Described PVC foam layer is made up of each raw material of following mass parts:

[0108] Polyvinyl chloride: 100 part...

Embodiment 3

[0127] This embodiment discloses a method for preparing an artificial leather with cold air permeability. The artificial leather is composed of a base fabric layer, a PVC adhesive layer, a PVC foam layer, a PVC dense layer and a surface layer from bottom to top.

[0128] The PVC dense layer is made up of the following raw materials in parts by mass:

[0129] Polyvinyl chloride: 100 parts, its K value is 80, plasticizer: 70 parts, described plasticizer is the mixture of DPHP and DOA, infrared reflection aid: 10.5 parts, stabilizer: 7 parts, it is specifically calcium Zinc stabilizer, color paste: 8 parts;

[0130] Mix the components of the above formula and stir for 10 to 15 minutes → three-roller grinding → vacuumize and stir for 40 minutes, control the viscosity: 3000 ~ 12000cps → filter to obtain a polyvinyl chloride dense layer slurry;

[0131] Described PVC foam layer is made up of each raw material of following mass parts:

[0132] Polyvinyl chloride: 100 parts, its K v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com