Photothermal conversion coating and preparation method thereof

A technology of light-to-heat conversion and coating, which is applied in the direction of coating, metal material coating process, superimposed layer plating, etc., can solve the problems that cannot meet the application requirements, and achieve low production cost, excellent optical performance, and weather resistance strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

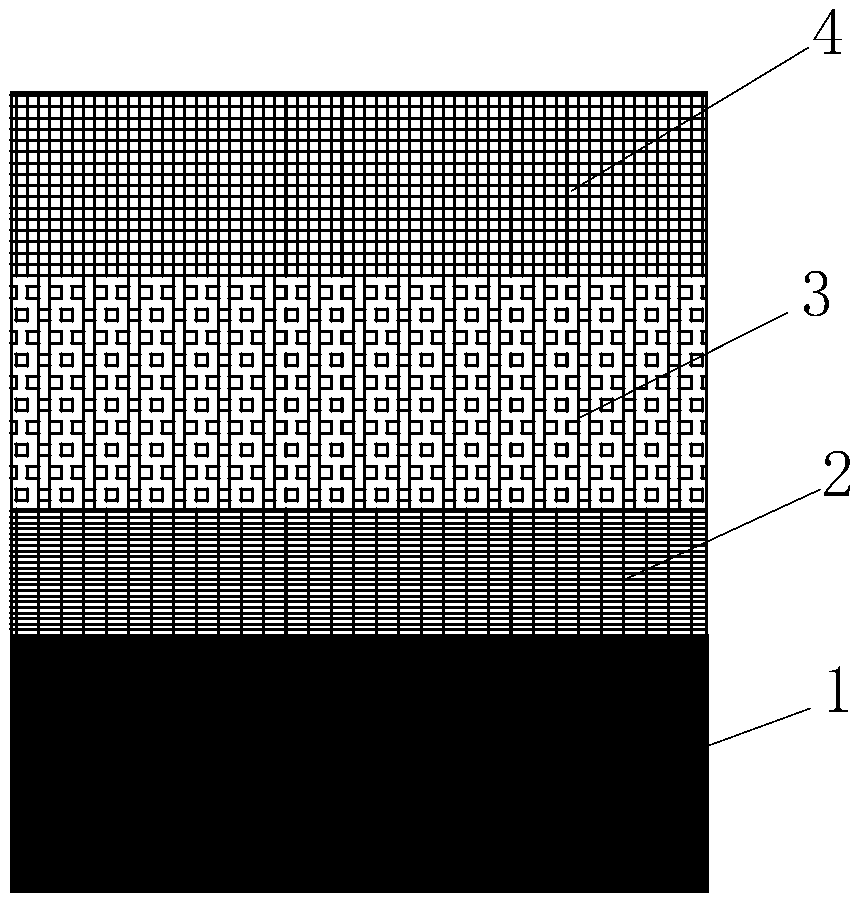

[0033] See figure 1 , the light-to-heat conversion coating in this embodiment includes a diffusion barrier layer 2 , a composite absorption layer 3 and an anti-reflection layer 4 arranged sequentially on a substrate 1 from bottom to top.

[0034]The substrate 1 is a substrate with infrared reflection function, and the material of the substrate 1 is aluminum, stainless steel, copper or glass; specifically, it can be one of aluminum strips or stainless steel (304, 316L) strips or copper strips or glass sheets , the substrate 1 in this embodiment is an aluminum strip.

[0035] The diffusion barrier layer 2 is a metal carbide layer with a thickness of 50-100 nm. The metal elements in metal carbides are transition metal elements of Group IVB~VIIB, and these metals have the characteristics of high melting point, high boiling point, high hardness and high density. The carbides of these transition metals have high melting points, stable chemical properties, low high-temperature diff...

Embodiment 2 to Embodiment 8)

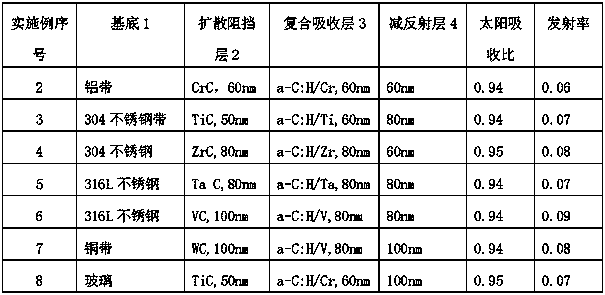

[0057] The composition of the coating of embodiment 2 to embodiment 8, each layer thickness and performance data see the following table:

[0058]

[0059] The preparation method of Examples 2 to 8 is the same as the coating of Example 1, and the corresponding metal target is replaced on the metal target during preparation. The detection method of solar absorptivity and emissivity is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com