Top blowing lance for refining and method for refining molten iron using the same

A molten iron and top-blowing technology, which is applied in furnaces, electric charge control, manufacturing converters, etc., can solve problems such as nozzle blockage for secondary combustion, inability to use top-blowing lances, and inability to obtain top-blowing lances, etc., and achieve iron yields Improvement, efficient oxidation refining, and productivity improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

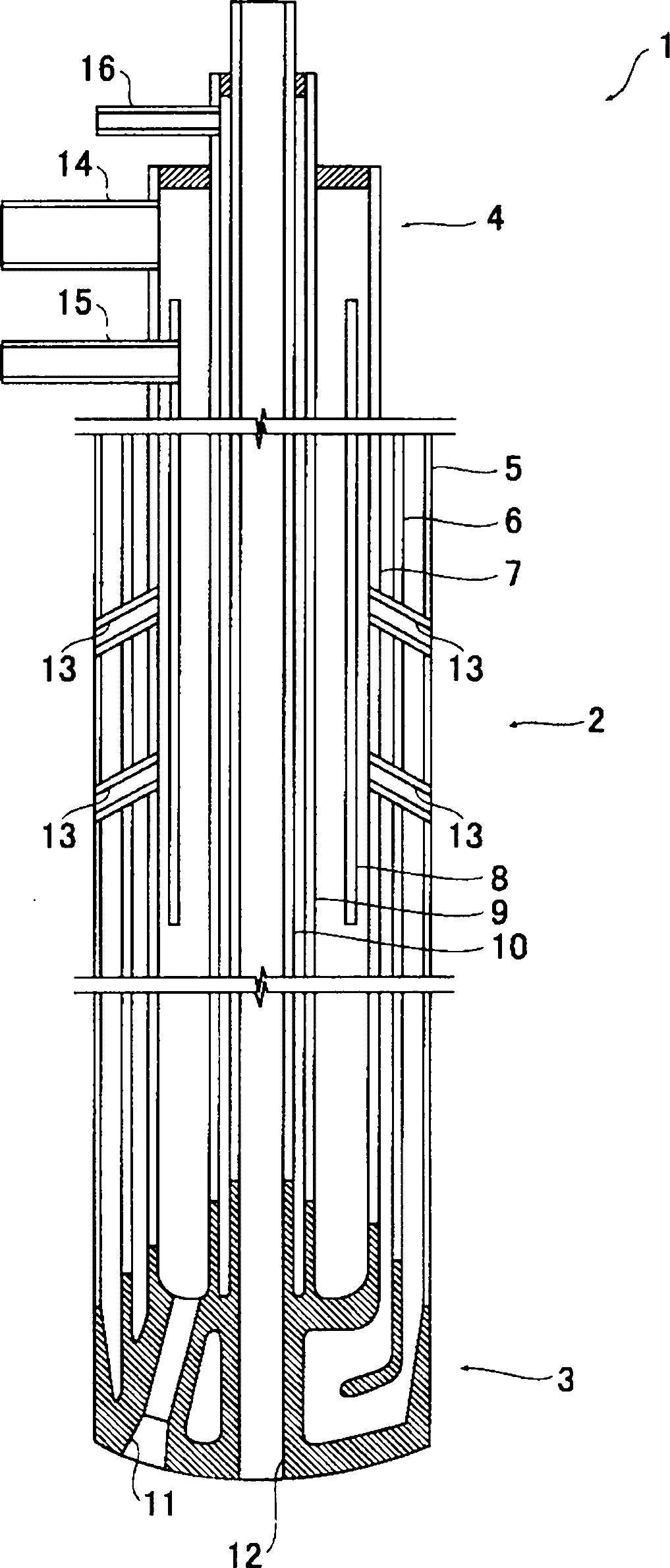

[0071] The molten iron discharged from the blast furnace is transported to a converter with a capacity of 300 tons after it is desiliconized using the cast bed of the blast furnace as required, and is utilized in the converter figure 1 The top-blown lance shown has been subjected to a total of four preliminary dephosphorization treatments (Examples 1 to 4 of the present invention). In addition, four main hole nozzles are arranged concentrically and uniformly. In addition, 8 nozzles for secondary combustion are arranged up and down in a concentric circle, and the angle θ (°) formed between the nozzles for secondary combustion and the top blowing lance makes the oxygen injection from the nozzles for secondary combustion The distance X (m) from the nozzle exit of the nozzle 13 for secondary combustion when the flow velocity of the stream reaches 30 m / sec satisfies the following formula (2).

[0072] [mathematical formula 2]

[0073] 0.10 ≤ ...

Embodiment 2

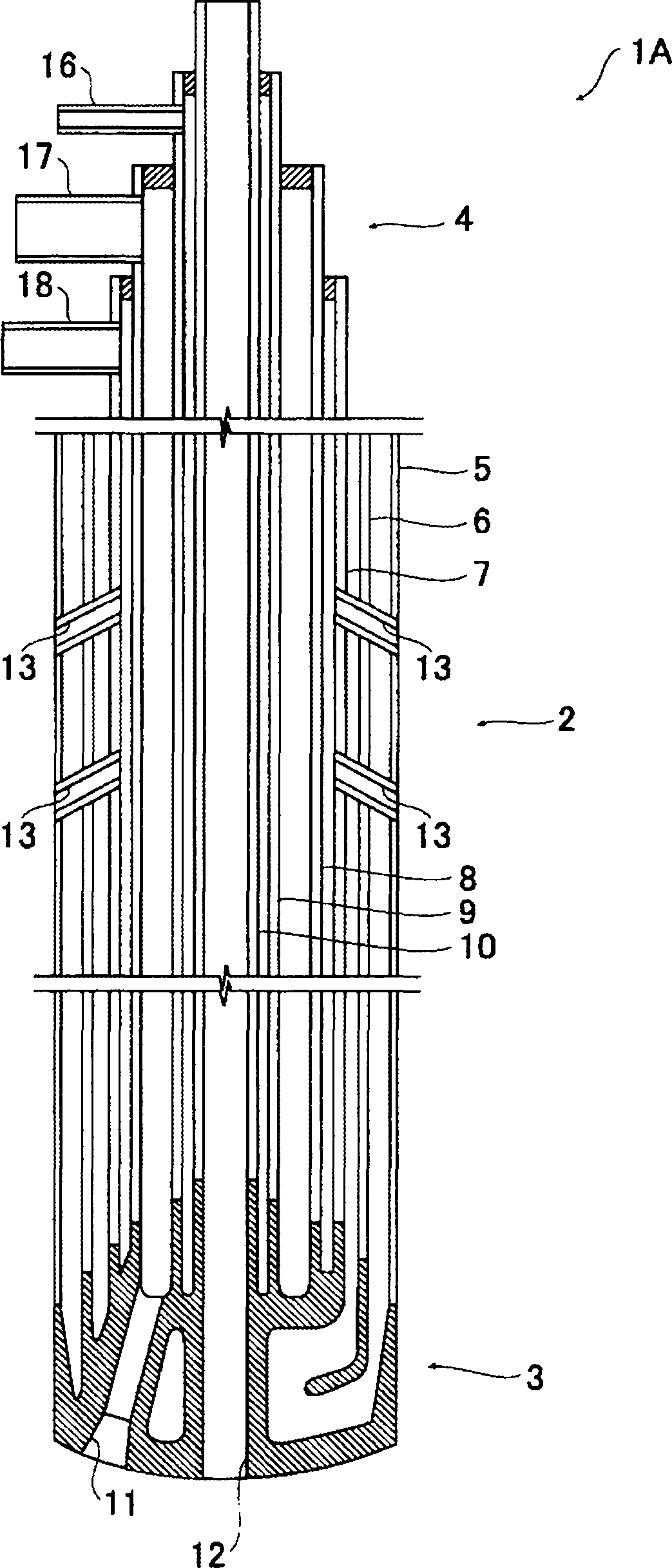

[0085] The molten iron discharged from the blast furnace is transported to a converter with a capacity of 300 tons after it is desiliconized using the cast bed of the blast furnace as required, and is utilized in the converter image 3 The shown top-blown lance was subjected to a total of two preliminary dephosphorization treatments (Examples 5-6 of the present invention).

[0086] In the dephosphorization process, the flow rate of oxygen from the nozzle for secondary combustion is controlled to be constant. O ) is the percentage of 100Q / Q O 12%. In this case, Xsin can also be confirmed

[0087] θ is in a range satisfying the above formula (2). Other dephosphorization treatment conditions were set to the same conditions as in Example 1. Table 2 shows the components and operating conditions of the molten iron before and after the dephosphorization treatment. The unit time consumption of CaO and the usage amount of solid oxygen source in Table 2 are the amounts per 1 ton of...

Embodiment 3

[0092] The molten iron discharged from the blast furnace is transported to a converter with a capacity of 300 tons after it is desiliconized using the cast bed of the blast furnace as required, and is utilized in the converter figure 1 and image 3 The top blowing lance shown has been subjected to preliminary dephosphorization treatment (Examples 7-8 of the present invention).

[0093] As a stirring gas, oxygen is fed from the tuyeres at the bottom of the converter at a rate of 0.3Nm per 1 ton of molten iron 3 / min flow blown in. The tuyeres at the bottom of the furnace are formed with a double-tube structure, and oxygen is blown in from the inner tube, and propane gas is blown in from the outer tube as cooling gas according to the flow rate of oxygen. Sintered ore (average particle size: 100 μm) of 6 kg of iron ore per 1 ton of molten iron was used as a solid oxygen source, and the solid oxygen source was sprayed from the sub-orifice nozzle of the pre-blow lance. The condi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com