Hydraulic excavator attachment control device

A technology for hydraulic excavators and auxiliary equipment, which is used in mechanical equipment, fluid pressure actuating devices, earth movers/shovels, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

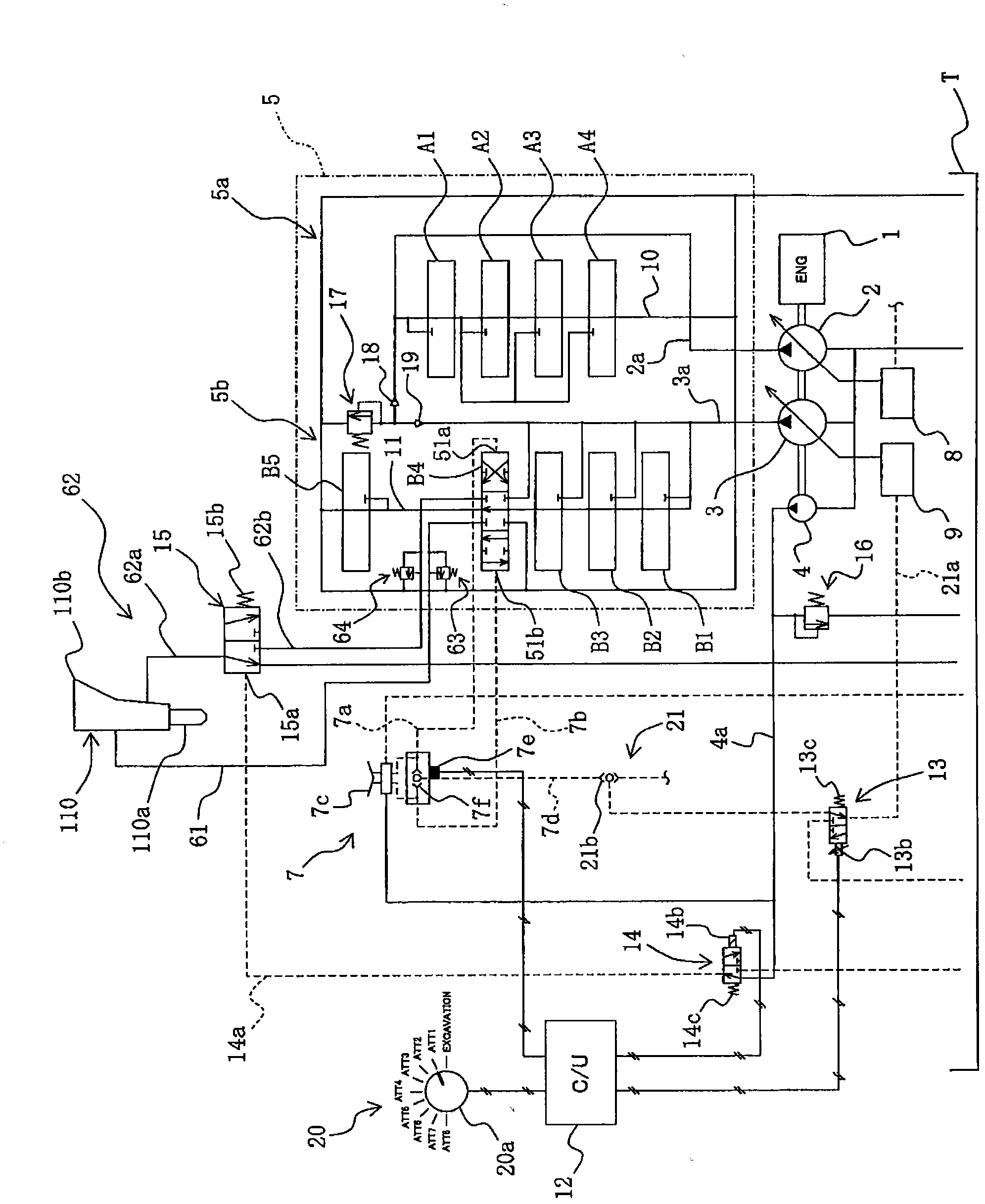

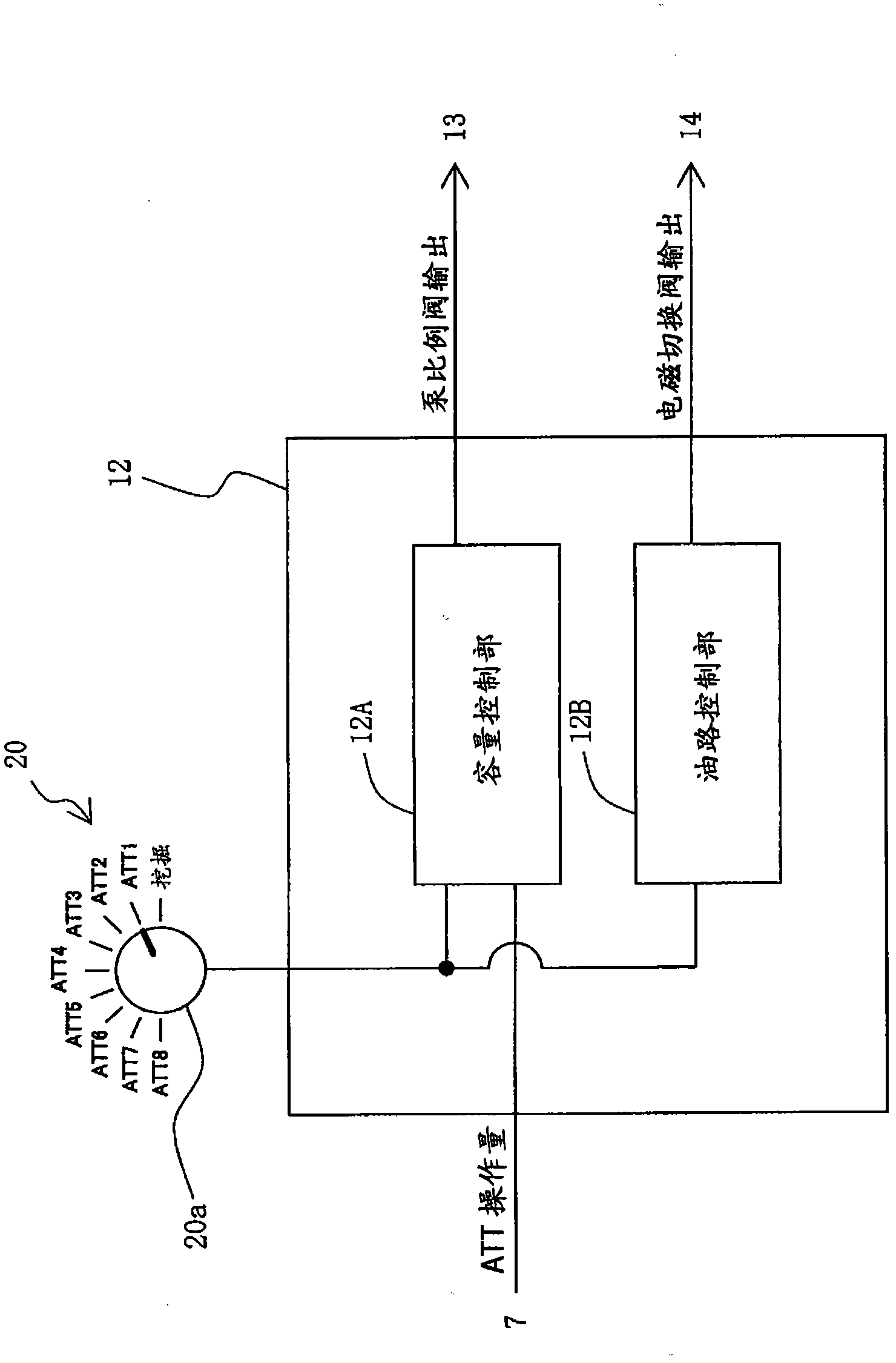

[0030] figure 1 It is a diagram schematically showing the overall configuration of a hydraulic circuit system of a hydraulic excavator having an attachment control device according to a first embodiment of the present invention.

[0031] exist figure 1 Among them, the hydraulic circuit system of the hydraulic excavator has: a prime mover 1 such as an engine; Driven fixed-capacity pilot pump 4; control valve unit 5 connected to the first and second hydraulic pumps 2, 3; rock crusher 110 as an accessory device connected to the control valve unit 5; connected to the control valve The multiple hydraulic actuators on the unit 5 include boom hydraulic cylinders 111, arm hydraulic cylinders 112, bucket hydraulic cylinders 113, and swing motors 107 (also refer to Figure 5 ); an operating pedal device 7 (accessory equipment operating mechanism) for operating ancillary equipment (a rock crusher 110 in this embodiment); A plurality of operating devices (not shown simultaneously) of t...

no. 2 approach

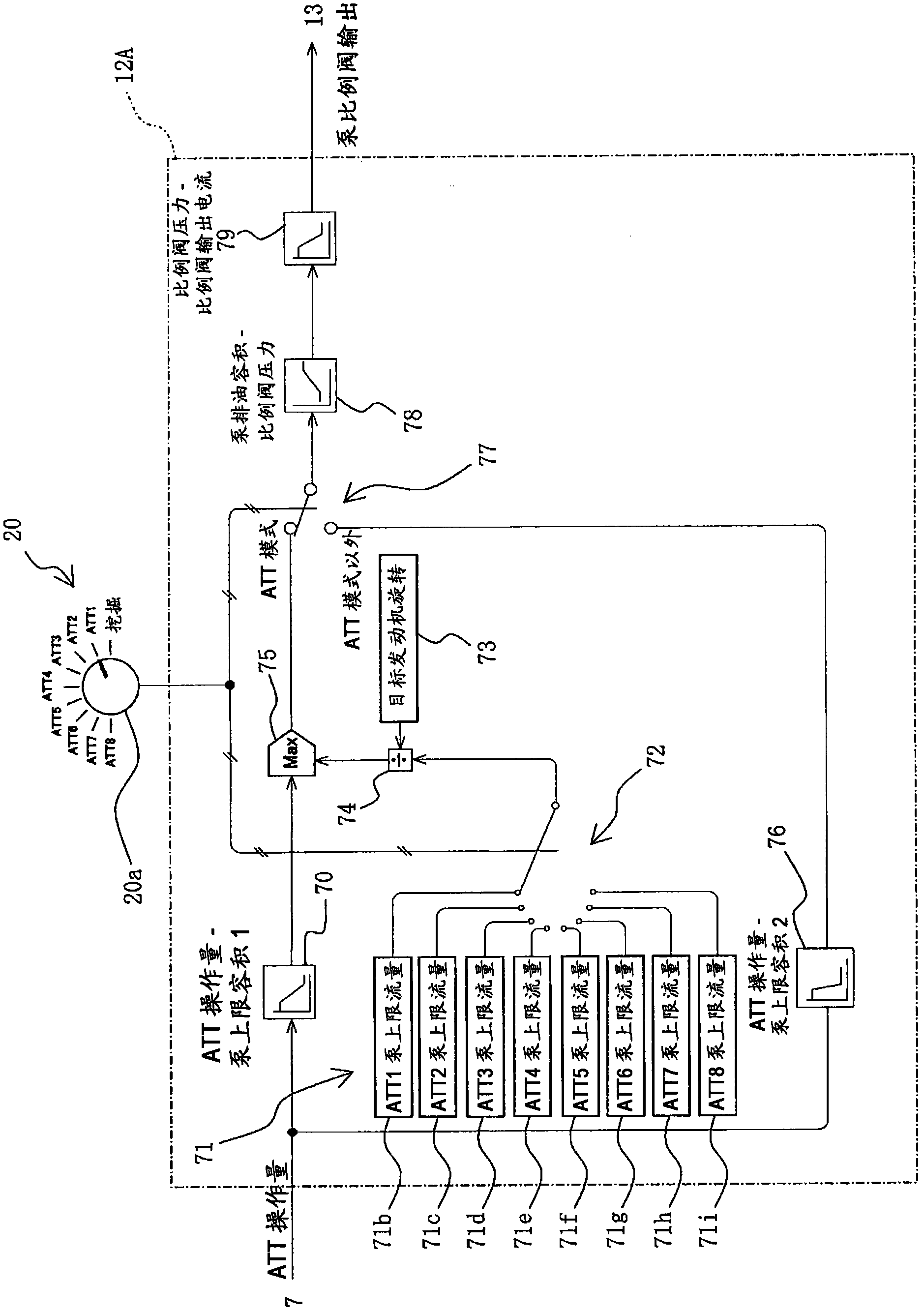

[0090] use Figure 6 ~ Figure 9 A second embodiment of the present invention will be described. Figure 6 It is a figure which schematically shows the whole structure of the hydraulic circuit system of the hydraulic excavator provided with the attachment control apparatus of this embodiment. Figure 7 is a block diagram showing the processing content of the control unit of this embodiment, Figure 8 It is a detailed figure showing the processing contents of the pump capacity control unit, Figure 9 It is a detailed figure which shows the processing content of a pilot pressure control part. In addition, in Figure 2 ~ Figure 4 In , for the sake of explanation, the accessory equipment selection means 20 are also shown together. In the figure, with Figure 1 to Figure 5 The same reference numerals are assigned to the same components shown in the drawings, and description thereof will be omitted.

[0091] exist Figure 6 Among them, the hydraulic circuit system of the hydra...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap