Surface-emitting LED cover, lighting device and display device

一种LED照明、LED光源的技术,应用在照明装置、照明装置的零部件、照明和加热设备等方向,达到成形性提高、脱模容易的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

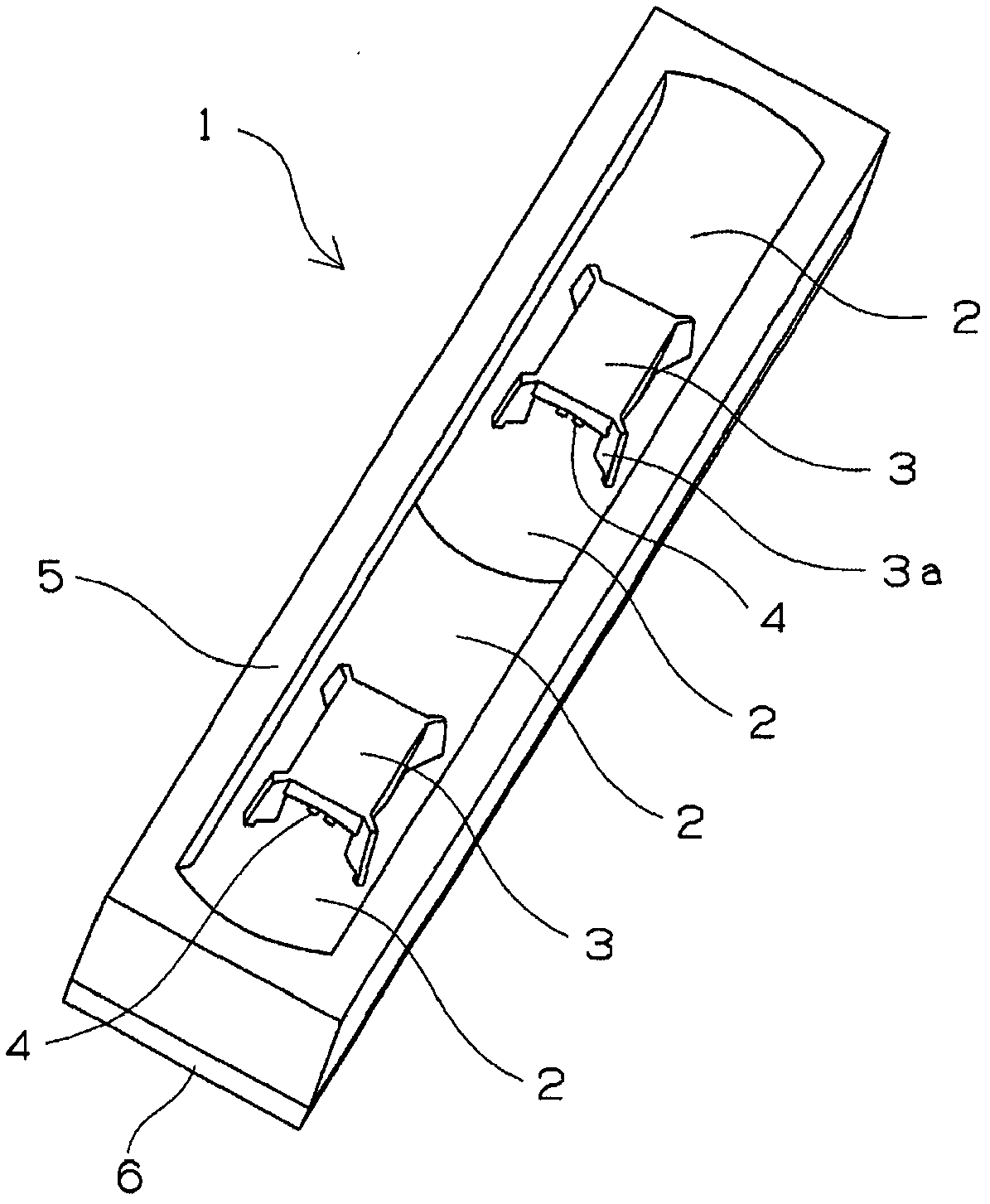

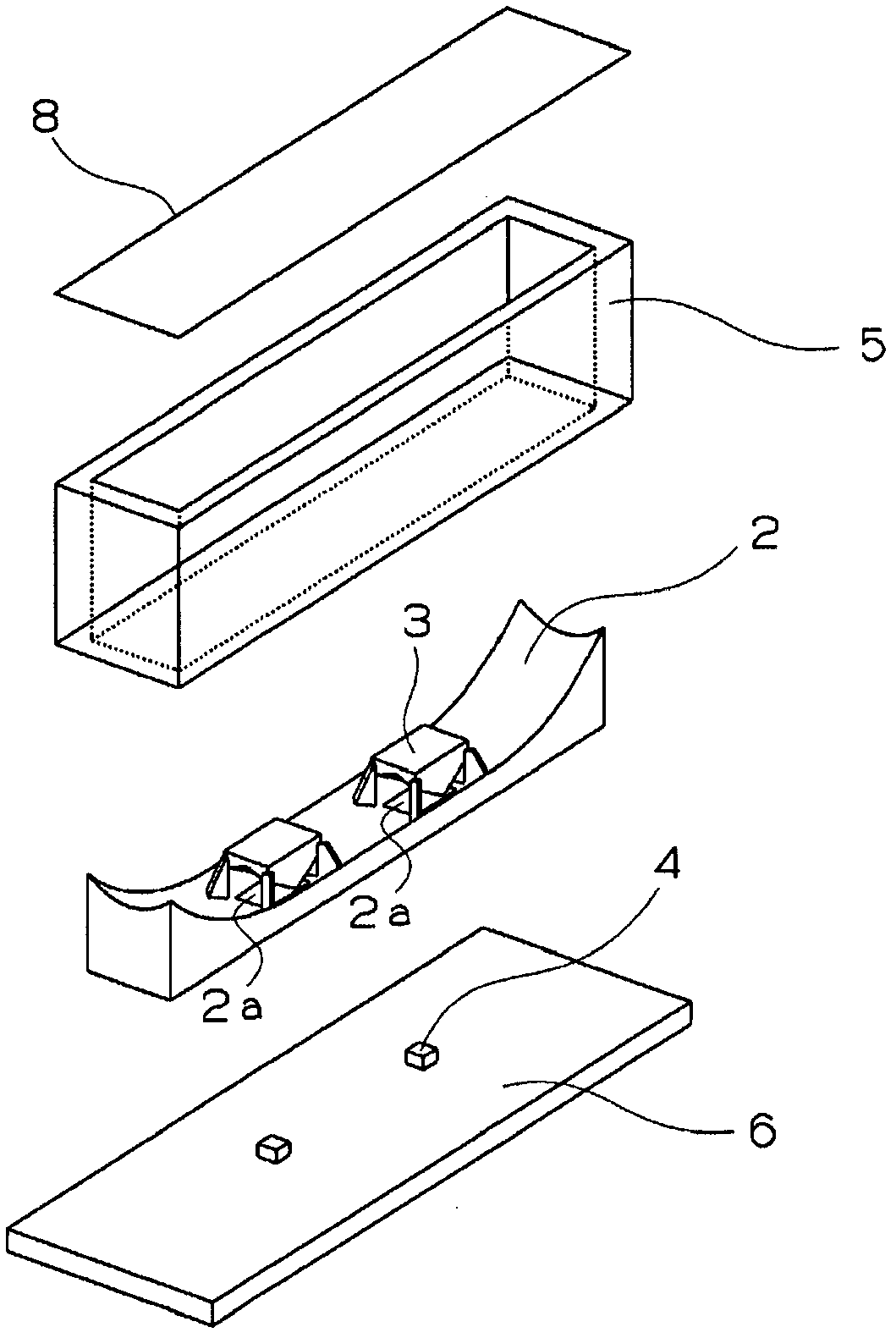

[0136] A LED surface-emitting cover with a main reflector and a sub-reflector is disposed in a casing with a surface-emitting opening of 4×26mm in size and a height of 7mm integrally formed with a highly reflective resin material.

[0137] As for the LED light source, two surface-mounted LED light sources with a directivity of 160 degrees were used at intervals of 9 mm. In addition, about the sub-reflector, used Figure 9 The reflected shape is shown.

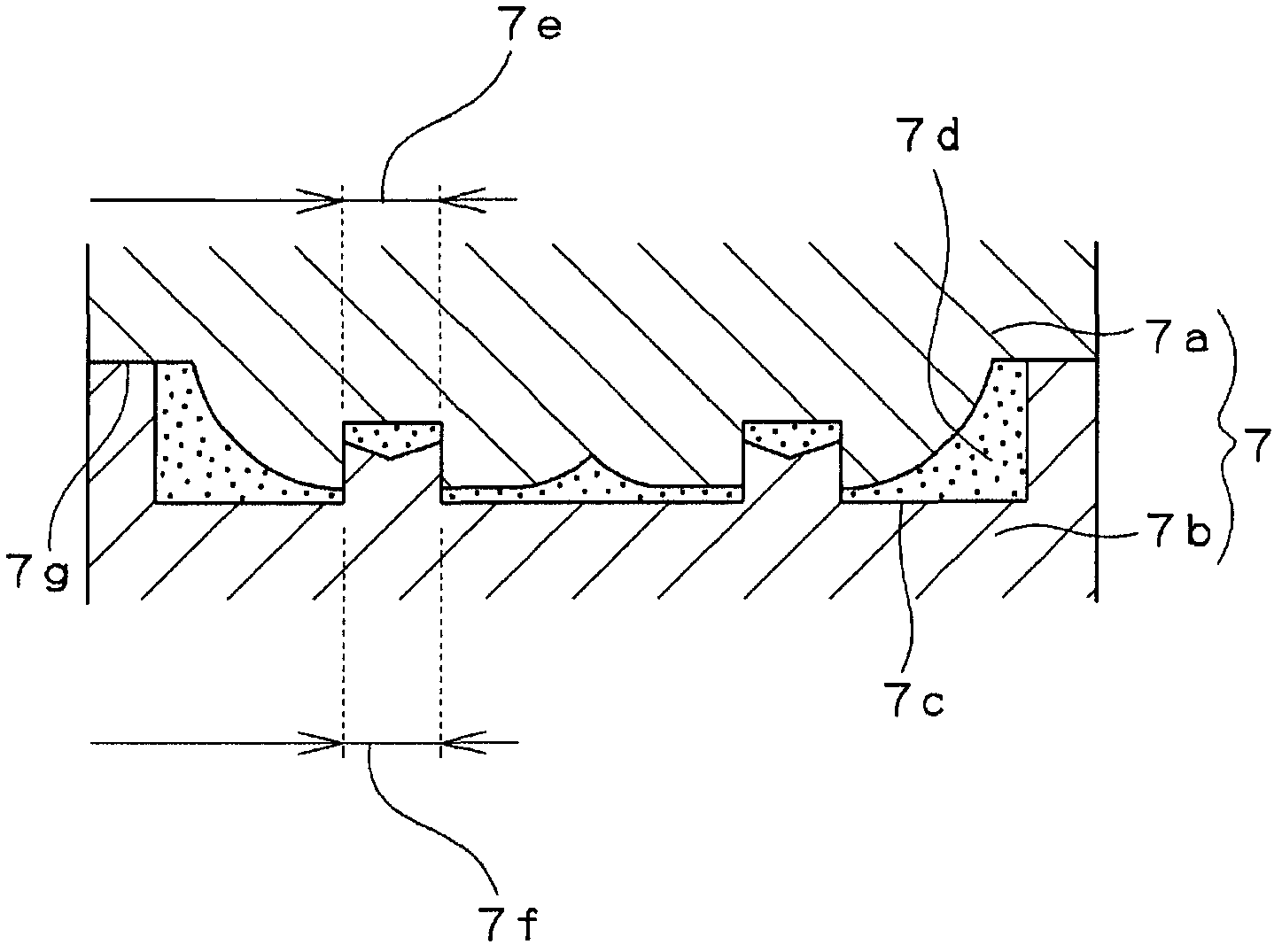

[0138] The distance from the reflective surface of the sub-reflector to the LED light source is set at 0.2-0.7 mm. In addition, the inclination angle β of the sub-reflector in the Y direction (longitudinal direction of the opening) section in which the LED light sources are arranged at approximately equal intervals is 120 to 140 degrees, and the angle γ in the orthogonal X section is 200 to 240 degrees. degree sub-reflector.

[0139] As for the reflection surface of the main reflector, an angled curvature is formed by a free...

Embodiment 2

[0146] A diffusion film (manufactured by KIMOTO Corporation, model D207, light transmittance 59%) was attached to the front surface of the housing of the LED lighting device obtained in Example 1 using a double-sided tape.

[0147] The obtained lighting device exhibited surface emission in which uniform luminance was obtained over the entire light emitting surface.

Embodiment 3

[0149] With respect to the diffusion film used in Example 2, semi-transmissive ink for lowering the transmittance to match the transmittance of the low-brightness portion was printed in layers on the high-brightness portion when no light-diffusion film was used. The layer-printed diffusion film was pasted on the front surface of the housing of the LED lighting device obtained in Example 1 by ultrasonic welding.

[0150] The obtained lighting device exhibited surface emission in which uniform luminance was obtained over the entire light emitting surface.

[0151] In addition, in order to reduce the transmittance so that the light-diffusing film is not used in the part with high brightness so as to match the part with low brightness, a layered non-dotted layer is used so that unevenness does not occur during lighting. Also in the case of a diffusion film printed with a non-transmissive ink, surface emission with uniform brightness over the entire light emitting surface is simila...

PUM

| Property | Measurement | Unit |

|---|---|---|

| visible light transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com