Acoustic wave device including a surface wave filter and a bulk wave filter, and method for making same

A technology of acoustic wave devices and surface acoustic waves, which is applied to electrical components, impedance networks, etc., and can solve problems such as independent optimization of filters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

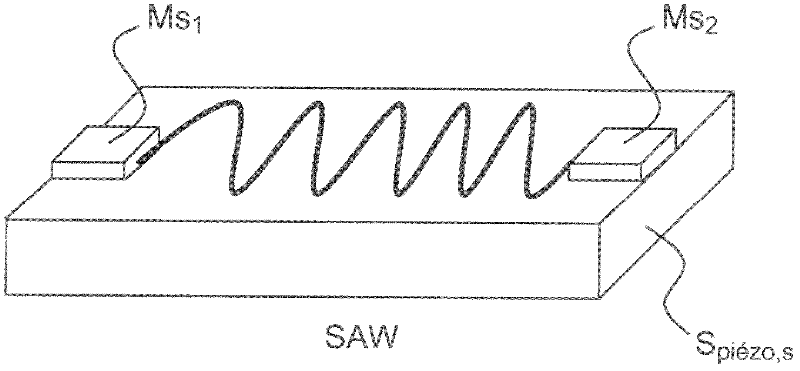

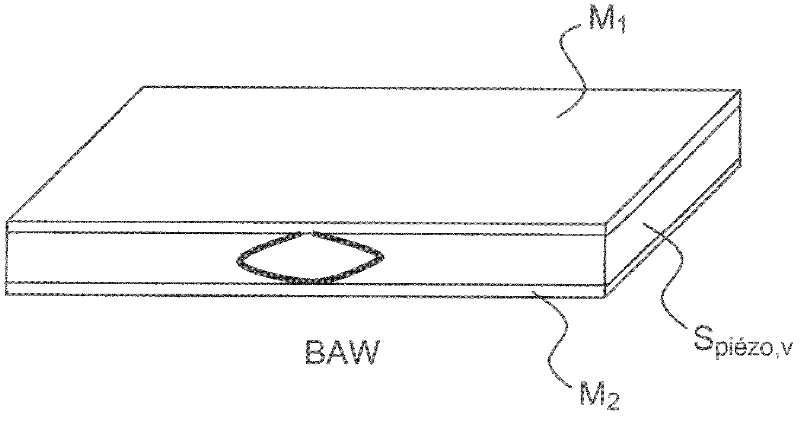

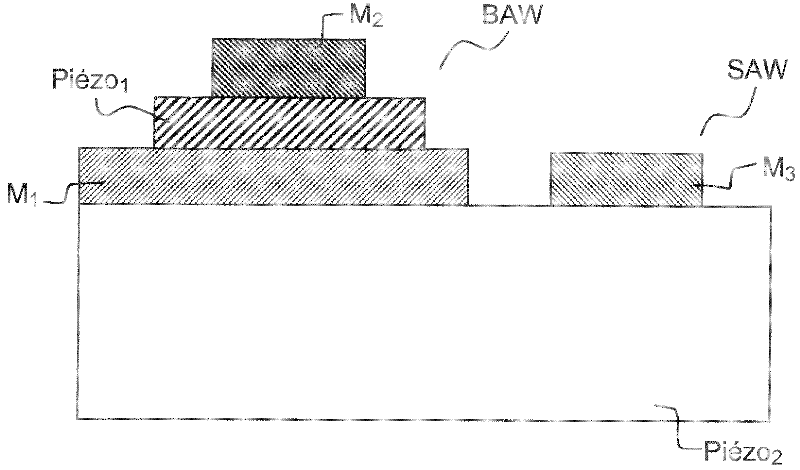

[0074] Generally speaking, if figure 2 As shown, the device of the present invention includes a substrate including piezoelectric material on at least a surface.

[0075] Advantageously, as described below, the substrate may be a piezoelectric material P iézo2 , the piezoelectric material P iézo2 The upper set has a layer comprising a metal M 1 ,, a layer of piezoelectric material P iézo1 and a layer of metal M 2 stack, thereby defining a first region in which a BAW-type bulk acoustic wave filter is fabricated. Advantageously, between the second piezoelectric material and the layer metal M 1 An acoustic decoupling layer is placed in between to decouple the two piezoelectric layers.

[0076] Substrate P iézo2 Also comprising in the second region a metallization assembly M for defining a set of electrodes on the surface of said piezoelectric material 3 , resulting in a surface acoustic wave filter.

[0077]Piezoelectric materials can be of different types: Piezoelectri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com