Filled type cotton fiber and preparation method thereof

A cotton fiber and filling technology, which is applied in the field of cotton fiber and its preparation, can solve the problems of fabric loss of functionality, affecting fabric feel, affecting fabric air permeability and feel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

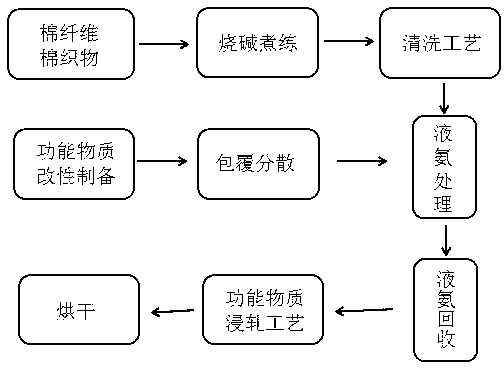

[0029] see figure 1 , in the preparation method of this filling type cotton fiber, comprise the following steps:

[0030] 1) Cotton fiber or cotton fabric caustic soda scouring process;

[0031] 2) Cleaning process;

[0032] 3) Modification and preparation of functional substances;

[0033] 4) Dispersion of functional substances in liquid ammonia;

[0034] 5) Liquid ammonia treatment process;

[0035] 6) Recovery of liquid ammonia;

[0036] 7) Padding process of functional substances;

[0037] 8) Dehydration and drying.

[0038] As a preferred version, the cotton fiber or cotton fabric caustic soda scouring process is used to remove the impurities in the cavity of the cotton fiber and the ports of the cavity of most cotton fibers are opened; then the cotton fiber is cleaned; the modified preparation of the functional substance is Refers to putting cotton fibers into liquid ammonia dispersed with functional particles, using liquid ammonia to infiltrate the cotton fiber c...

Embodiment 2

[0051] The filling cotton fiber is prepared by the preparation method of the filling cotton fiber in Example 1, and the specific steps are not described in detail.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com