Full built-in expandable anterior spinal fixation system

An internal fixator and built-in technology, which is applied in the field of medical devices, can solve the problems that the plate and the side of the vertebral body cannot be completely adhered to, cannot resist the pressure load, and internal fixation fails. It has good clinical application prospects and is beneficial to bone growth. Into and overcome the effect of poor anti-rotation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

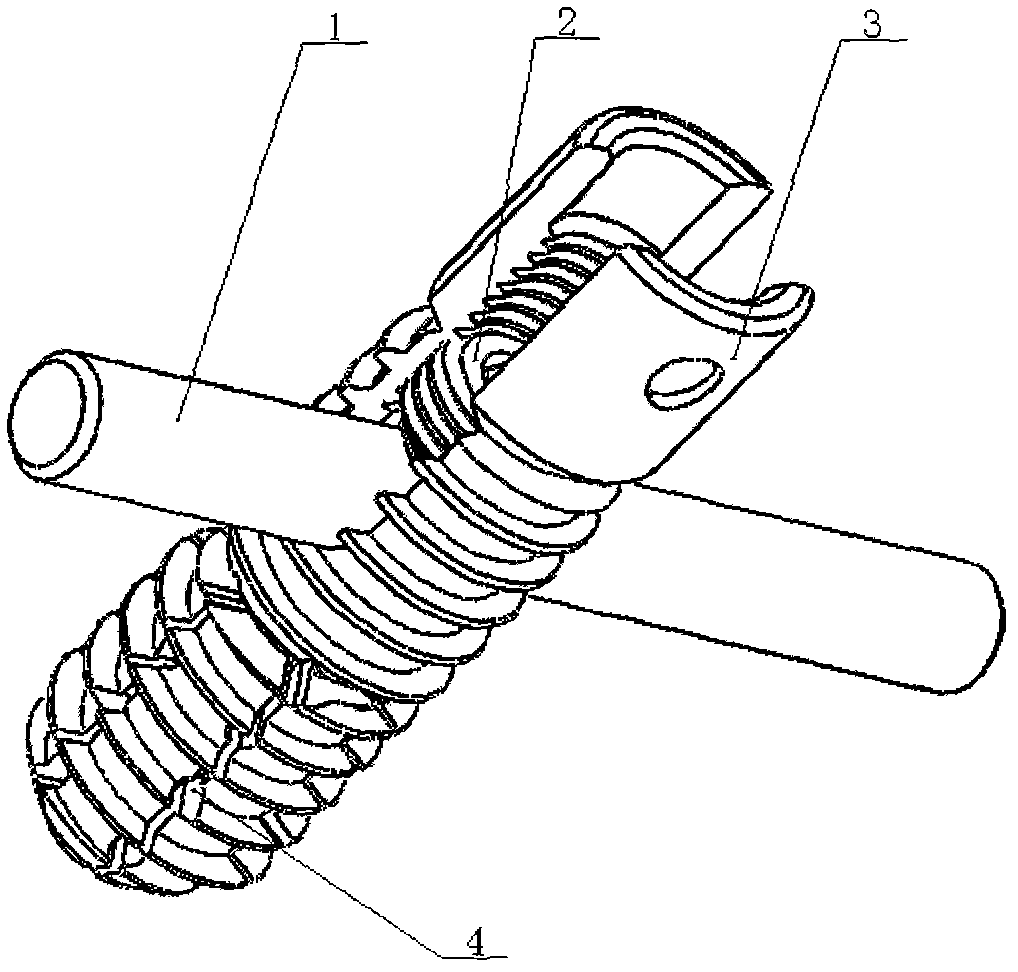

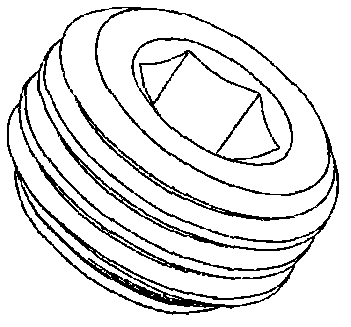

[0018] The fully built-in expandable anterior spinal internal fixator system consists of a connecting rod (1), a screw plug (2), an expansion nail body (3), and an expansion core (4), and is characterized in that the expansion core (4) is Stepped rod shape, one end head has threads and inner hexagonal hole, the other end head is tapered; the expansion nail body (3) is a hollow structure with stepped through holes, the inner and tail of the aperture are threaded, and the outer surface is threaded. Annular groove, the tip of the nail body is evenly divided into six petals, small holes are distributed on the leaflets, the tail of the nail body has a U-shaped groove, and there are two symmetrical holes on the outer surface of the tail. First, after exposing the diseased vertebra and its upper and lower adjacent vertebral bodies, implant expansion nails (3) in the upper and lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com