High negative pressure non-clogging drainage tube

A drainage tube, non-blocking technology, used in catheters, other medical devices, hypodermic injection devices, etc., can solve the problems of not easy to pull out, easy to form adhesion, untimely drainage, etc., to avoid adhesion and relieve pain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

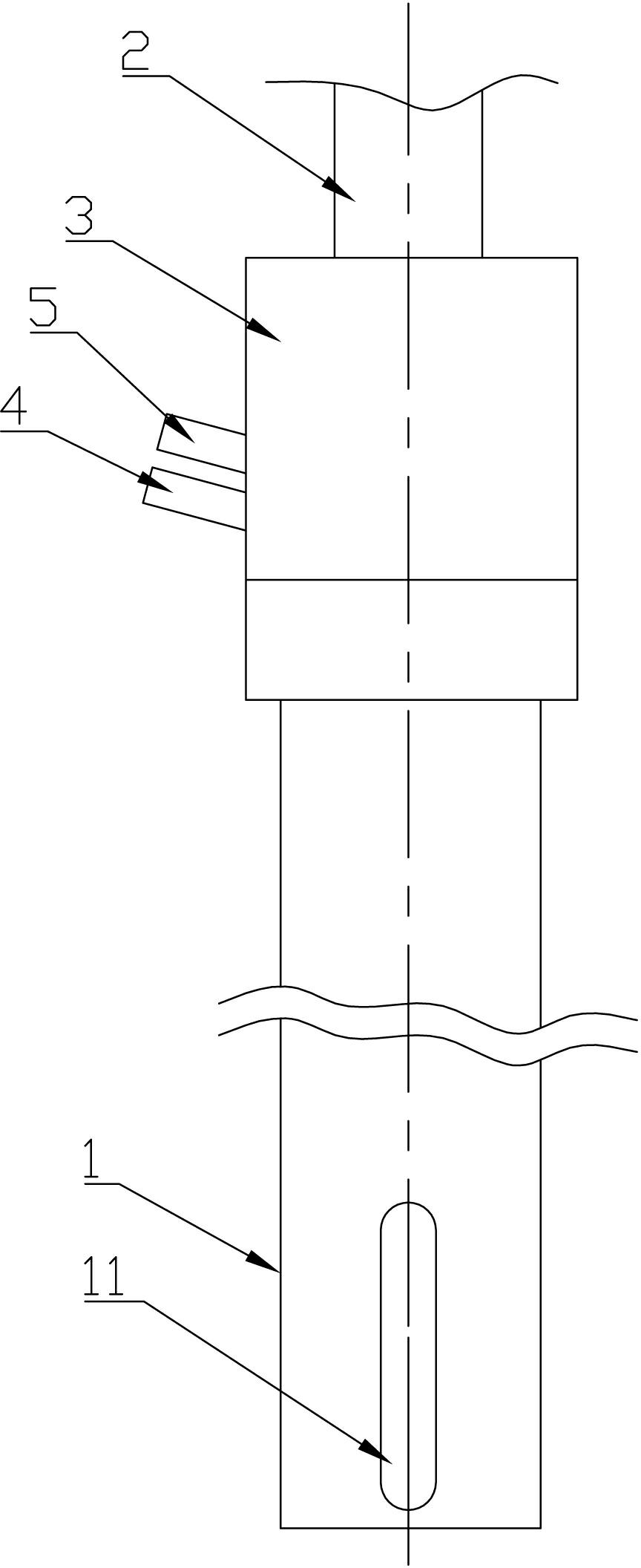

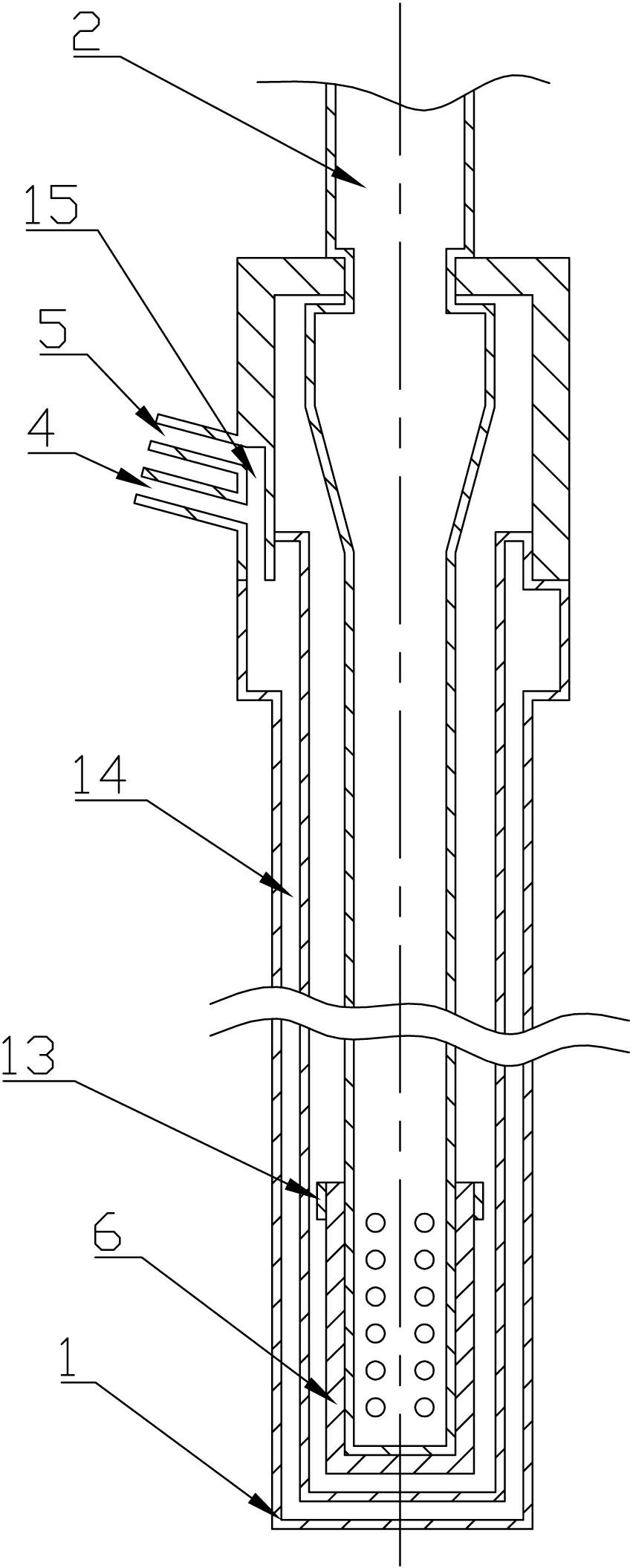

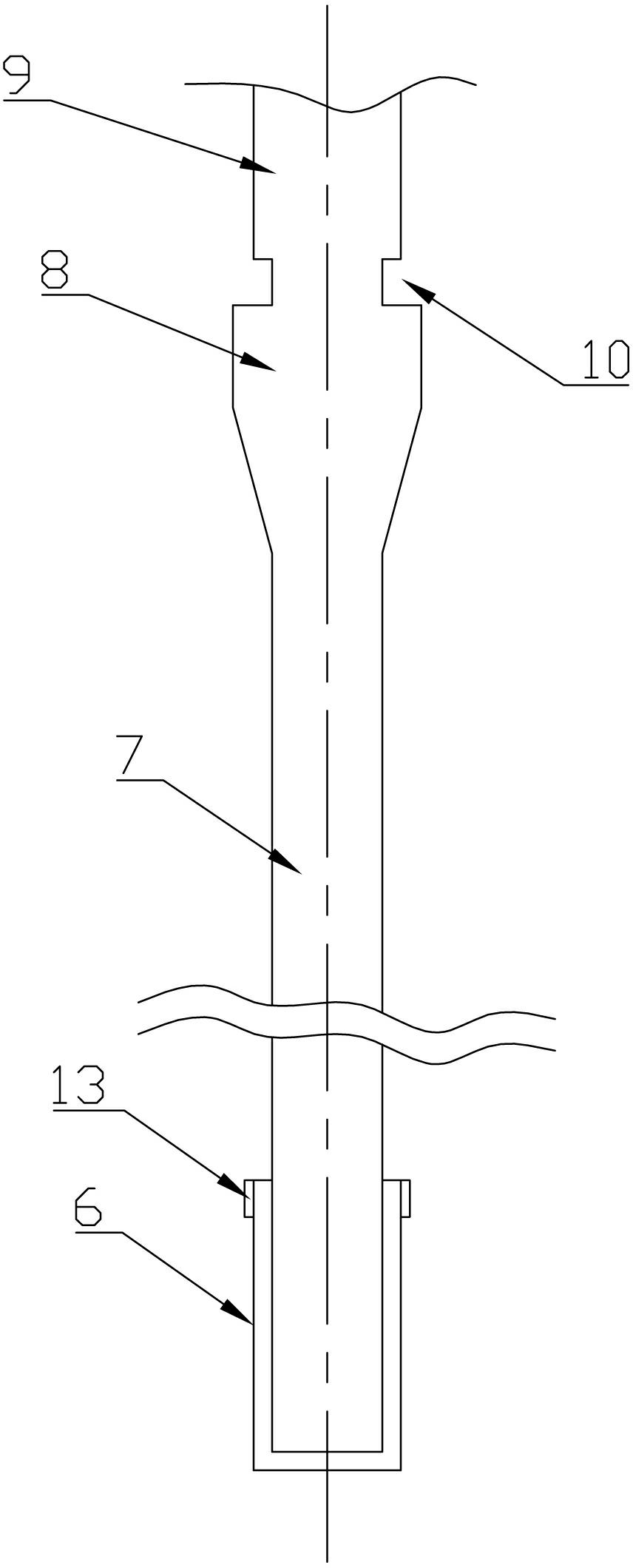

[0022] The application of the present invention in postoperative drainage will be described in detail below in conjunction with the accompanying drawings.

[0023] refer to Figure 1 to Figure 5 , a high negative pressure non-clogging drainage tube, comprising a built-in sleeve 1 with a plurality of sleeve drainage side holes 11 on the outer surface and a built-in drainage tube 2 with a plurality of inner tube drainage side holes on the outer surface, the built-in drainage tube 2. There is a built-in sleeve 1 outside the outer casing. The end surface of the built-in drainage tube 2 is provided with a drainage side hole of the inner tube, and a filter layer 6 is wrapped on the surface. 2 can be disassembled from the inner casing 1.

[0024] By setting the filter layer 6 on the built-in drainage tube 2 and the built-in drainage tube 2 can be replaced, then in the closed high negative pressure suction, the negative pressure is evenly distributed on the surface of the filter laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com