Absorbent for selectively removing H2S and organic sulfur

An absorbent, H2S technology, applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems that have not yet been reported on polyamide-amine compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

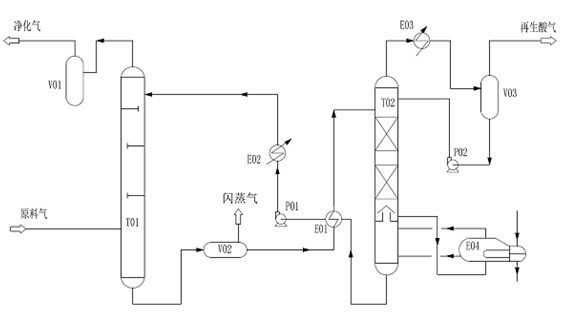

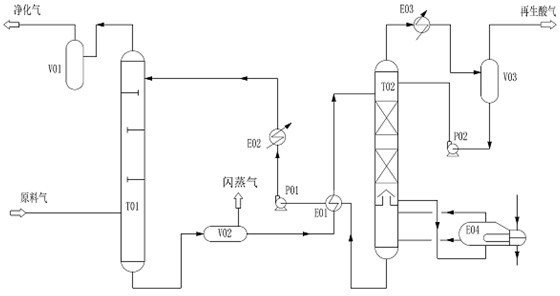

Image

Examples

Embodiment 1

[0026] Raw natural gas (pressure 1.5MPa, room temperature, H 2 S 1.0%, CO 2 5.8%, COS 200mg / m 3 ), using the absorbent of the present invention, with 48%w of MDEA and 2% of the polyamide-amine dendrimers stirred evenly after the composite desulfurization solution is absorbent, purified gas H 2 S3 , H in the regenerated acid gas 2 S content > 30%.

Embodiment 2

[0028] Raw natural gas (pressure 4.6 MPa, room temperature, H 2 S 4.8%, CO 2 10.2%, COS 200mg / m 3 , MeSH 200mg / m 3 ), using the absorbent of the present invention, the polyamide-amine with 40%w of MDEA, 5% of 2-amino-2 methyl-1 propanol and 5% of ethylenediamine as the core is uniformly mixed for desulfurization The solution is the absorbent, and the purified gas H 2 S3 , H in the regenerated acid gas 2 S content>50%.

Embodiment 3

[0030] Raw natural gas (pressure 8.3MPa, room temperature, H 2 S 10.1%, CO 2 21.2%, COS 300mg / m 3 , COS 50mg / m 3 , MeSH 500mg / m 3 , EtSH 50 mg / m 3 ), using the absorbent of the present invention, using 25%w of MDEA, 10% of hydroxyethylpiperazine and 15% of ethylenediamine as the core polyamide-amine mixture to stir the compound desulfurization solution as the absorbent, Purified gas H 2 S2 The sum of organic sulfur such as , MeSH and EtSH is 150mg / m 3 around, the H in the regenerated acid gas 2 S content>50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com