Two-level absorption desulfuration denitration demercuration particulate matter 2.5 (PM2.5) removal washing tower

A technology of desulfurization, denitrification, mercury removal and scrubber, which is applied in the field of flue gas purification, can solve the problems of increased space height of reactor equipment, low removal efficiency, high construction cost, etc., achieve low one-time investment cost, improve removal efficiency, The effect of promoting reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

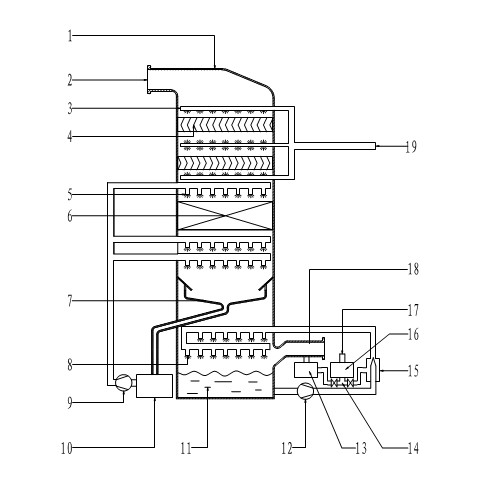

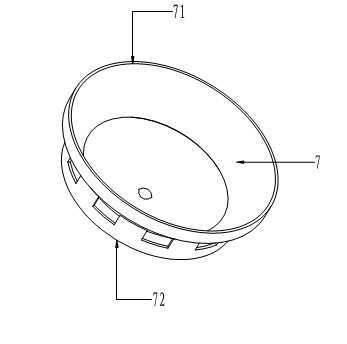

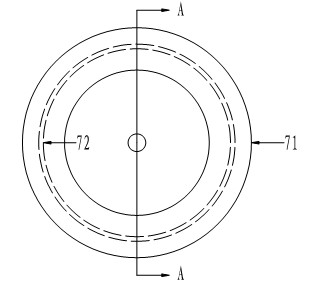

[0024] Such as figure 1 , a two-stage absorption, desulfurization, denitrification, and mercury removal scrubber 1 for removing PM2.5, including a flue gas outlet 2 arranged on the top of the scrubber 1 and a flue gas inlet 18 on the lower side, and a two-stage absorption device is arranged inside the scrubber 1: The primary absorption device includes the primary absorbent circulation pump 12 that drives the absorbent 11 in the tower to flow upward, the primary absorbent atomization pipe 8 that sprays out the liquid, and the primary absorbent circulation pump 12 and the primary absorbent. Venturi tube 15 between atomizing tubes 8. The secondary absorption device includes a recoverer 7, an external storage tank 10 connected to the recoverer 7 through a pipeline, a secondary absorbent circulation pump 9 that drives the absorbent outside the tower to flow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com