Special high-precision intelligent pump for hydraulic torque wrench and method for controlling hydraulic torque wrench

A technology of torque wrench and hydraulic pump, which is applied in the field of hydraulic torque wrench special pump and hydraulic torque wrench control, and can solve the problems of difficulty in realizing automatic operation of hydraulic torque wrench, low efficiency, and inability to intelligently judge bolt tightening torque, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

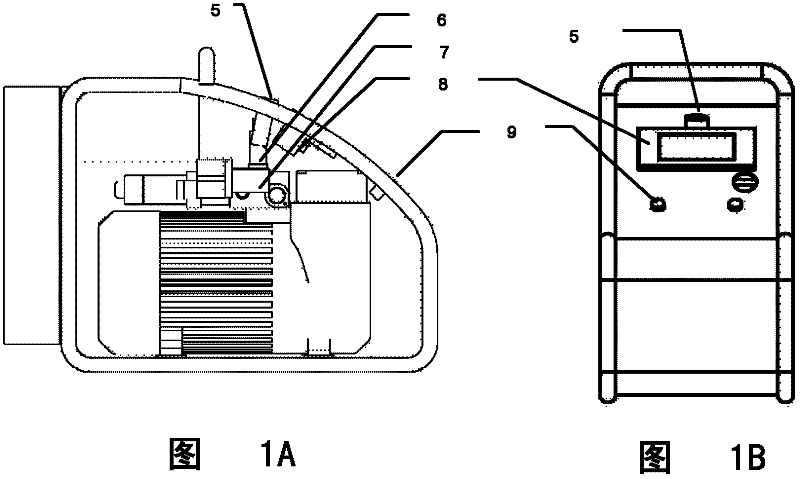

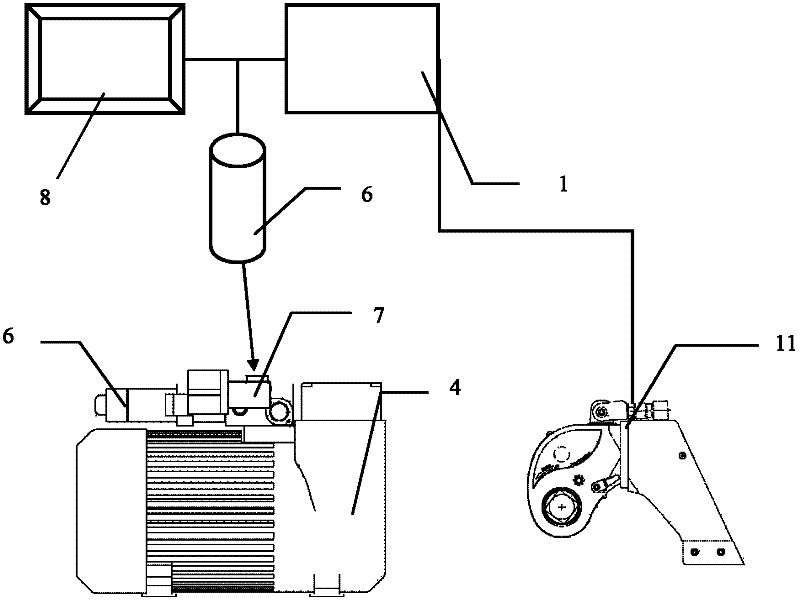

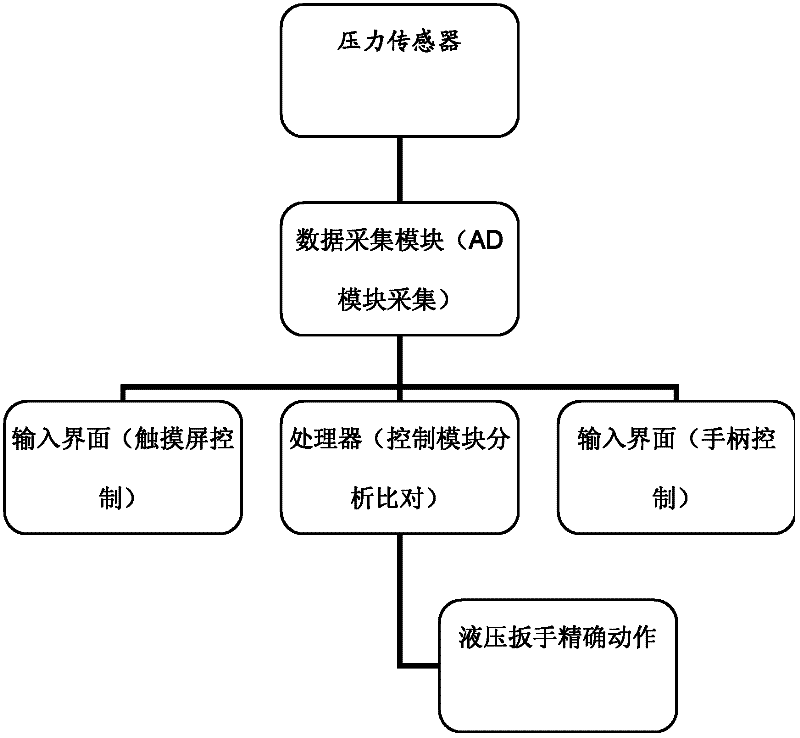

[0022] like Figure 1A , Figure 1B as well as figure 2 As shown, in an embodiment of the present invention, the intelligent high-precision hydraulic torque wrench special pump includes a hydraulic unit, a control unit and an execution unit, wherein the hydraulic unit 4 is a hydraulic pump body. The control unit includes a data collector 1 , a pressure sensor 6 and a processor 8 . The execution unit includes an electromagnetic reversing valve 3 (with high and low pressure output ports) and an intelligent pressure regulating valve 7 with intelligent compensation function. The data collector 1 can be integrated in the processor 8 .

[0023] In the intelligent high-precision hydraulic torque wrench special pump, the hydraulic unit 4 provides power, the control units 6, 8, 1 collect and process relevant data, and the execution units 3, 7 execute the hydraulic wrench 11 to realize the automatic control of the precise action of the hydraulic wrench.

[0024] refer to figure 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com