Ball-hinged coupling mechanism of locator based on three-dimensional force sensor

A connection mechanism and sensor technology, applied in aircraft assembly, aircraft parts, ground devices, etc., can solve the problems of connection efficiency and precision, attitude adjustment cycle and accuracy are greatly affected, and it is difficult to assemble without stress, so as to achieve stress-free Assembling, shortening the assembly and debugging cycle, and convenient placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

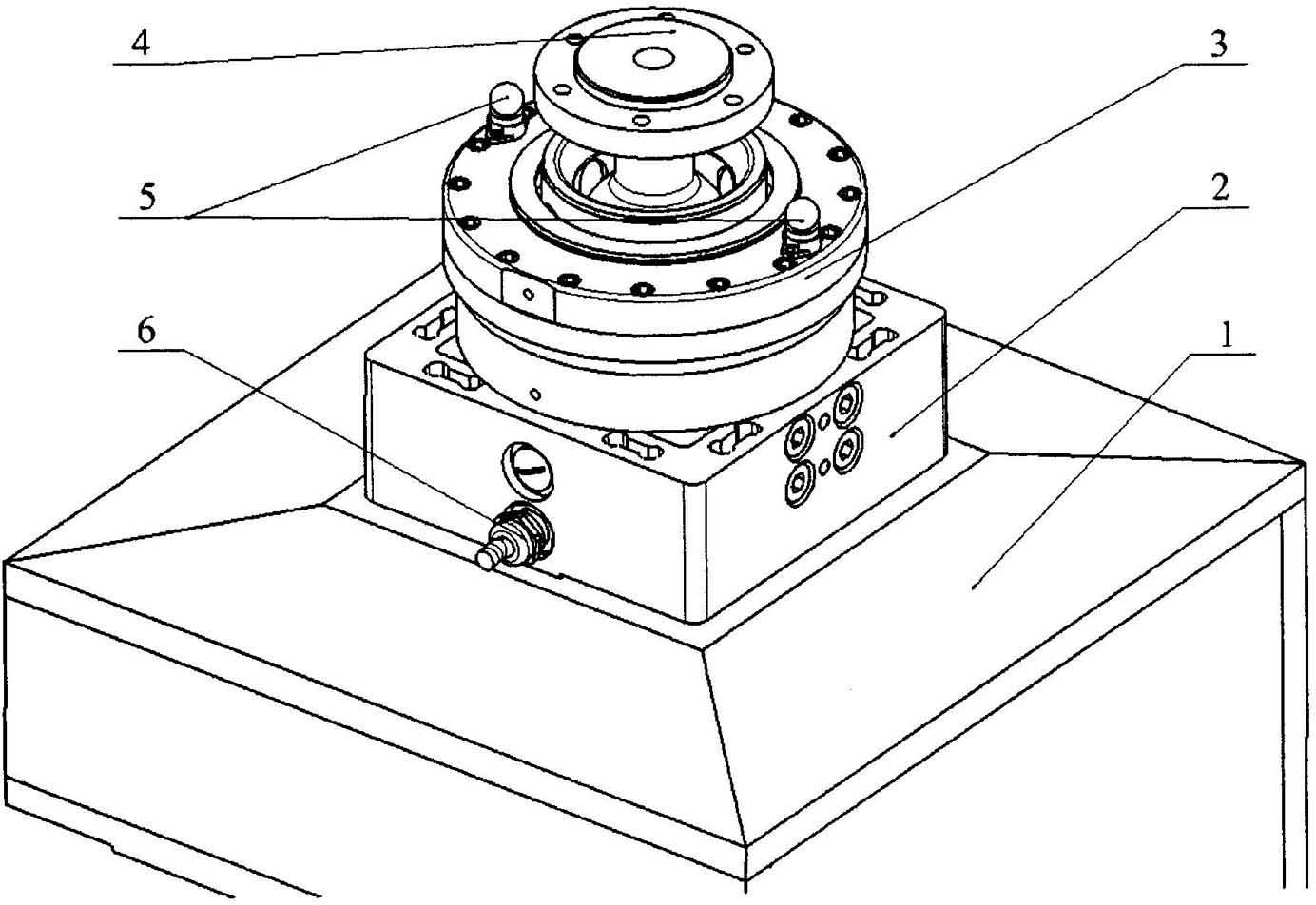

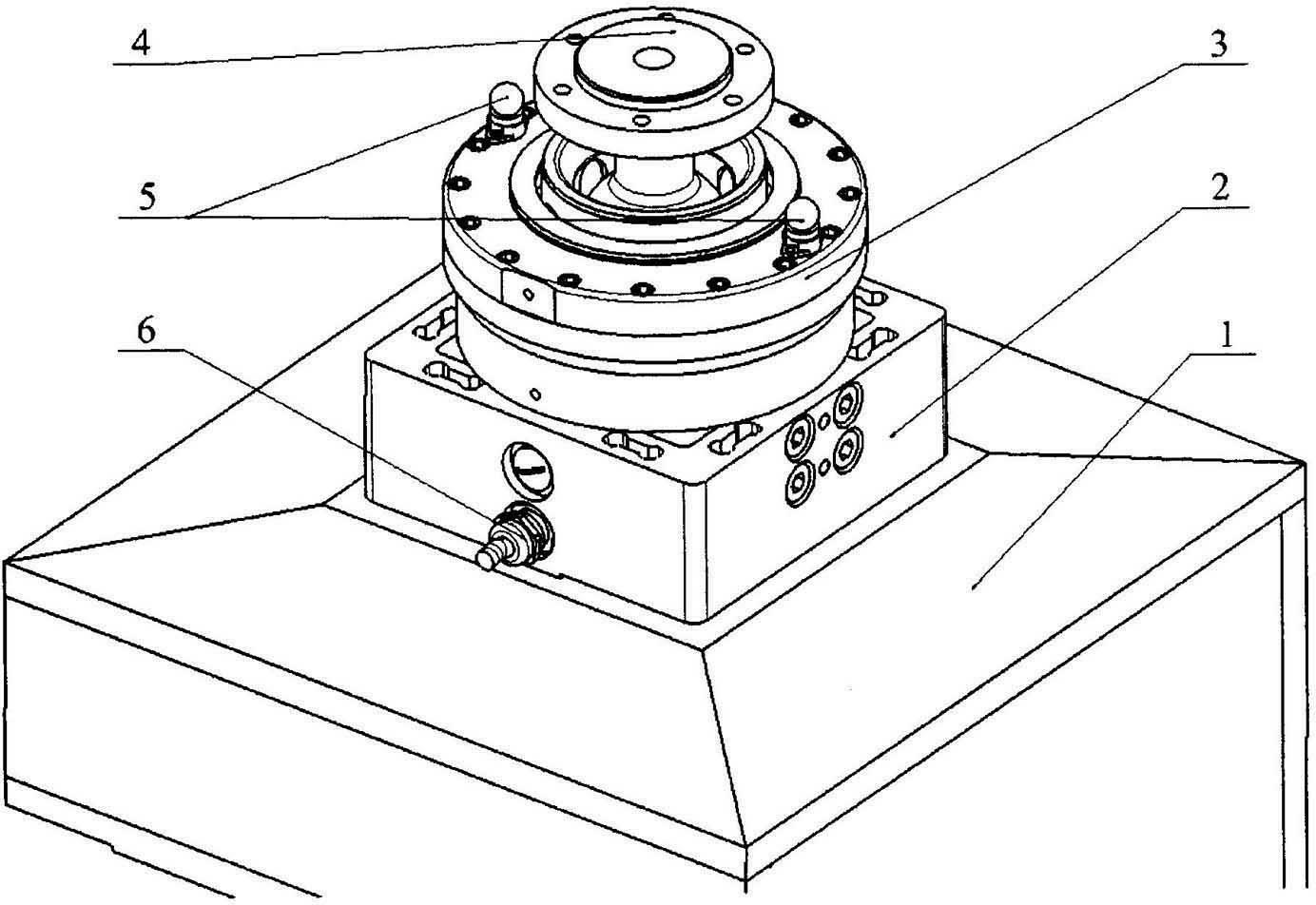

[0015] Such as figure 1 As shown, a three-dimensional force sensor-based ball-and-twist connection mechanism of a positioner is provided with a three-dimensional force sensor 2 on the positioner 1. Process ball head 4, the upper end of the process ball head is a flange structure, and the lower end is a sphere structure, so that it has the freedom to rotate around the center of the sphere; two laser tracker targets are symmetrically arranged along the diameter direction on the upper surface of the ball twist connection unit 3 5. Used to determine the sphere center coordinates of the craft ball head; the data line of the three-dimensional force sensor 2 is derived through the three-dimensional force sensor connection port 6 at the side end, and the data line communicates with the control system.

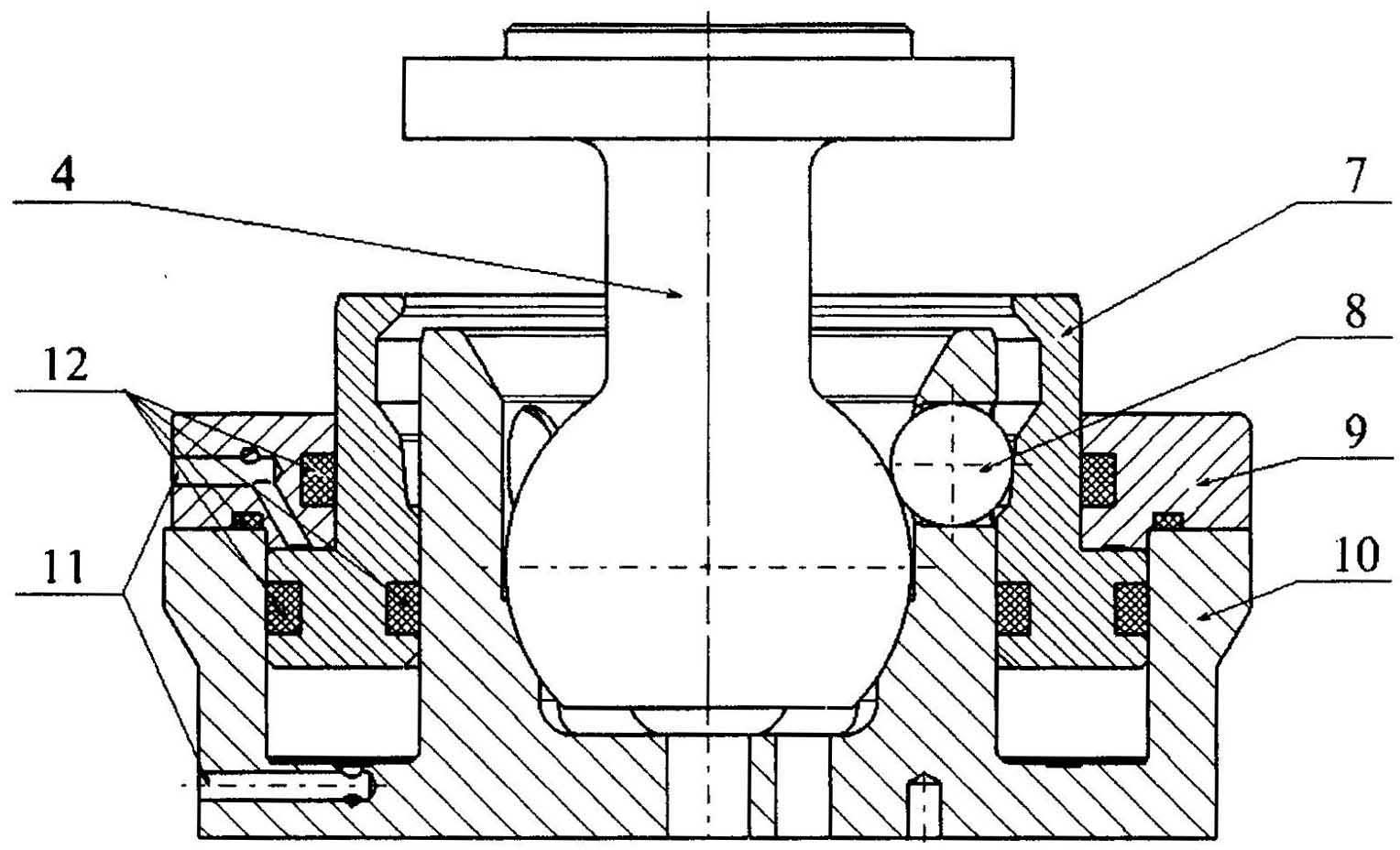

[0016] Such as figure 2 As shown, the specific structure of the ball joint connection unit 3 is as follows: the center of the ball holder body 10 is a spherical surface, and the ball hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com