Inflatable automatic bag cutting device for slicing container bag

A space bag, inflatable technology, applied in the field of chemical fiber textiles, can solve the problems of affecting product quality, inclusion of air bubbles, inconvenient operation, etc., and achieve the effect of reducing labor intensity of workers, ensuring dryness and improving product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings of the description.

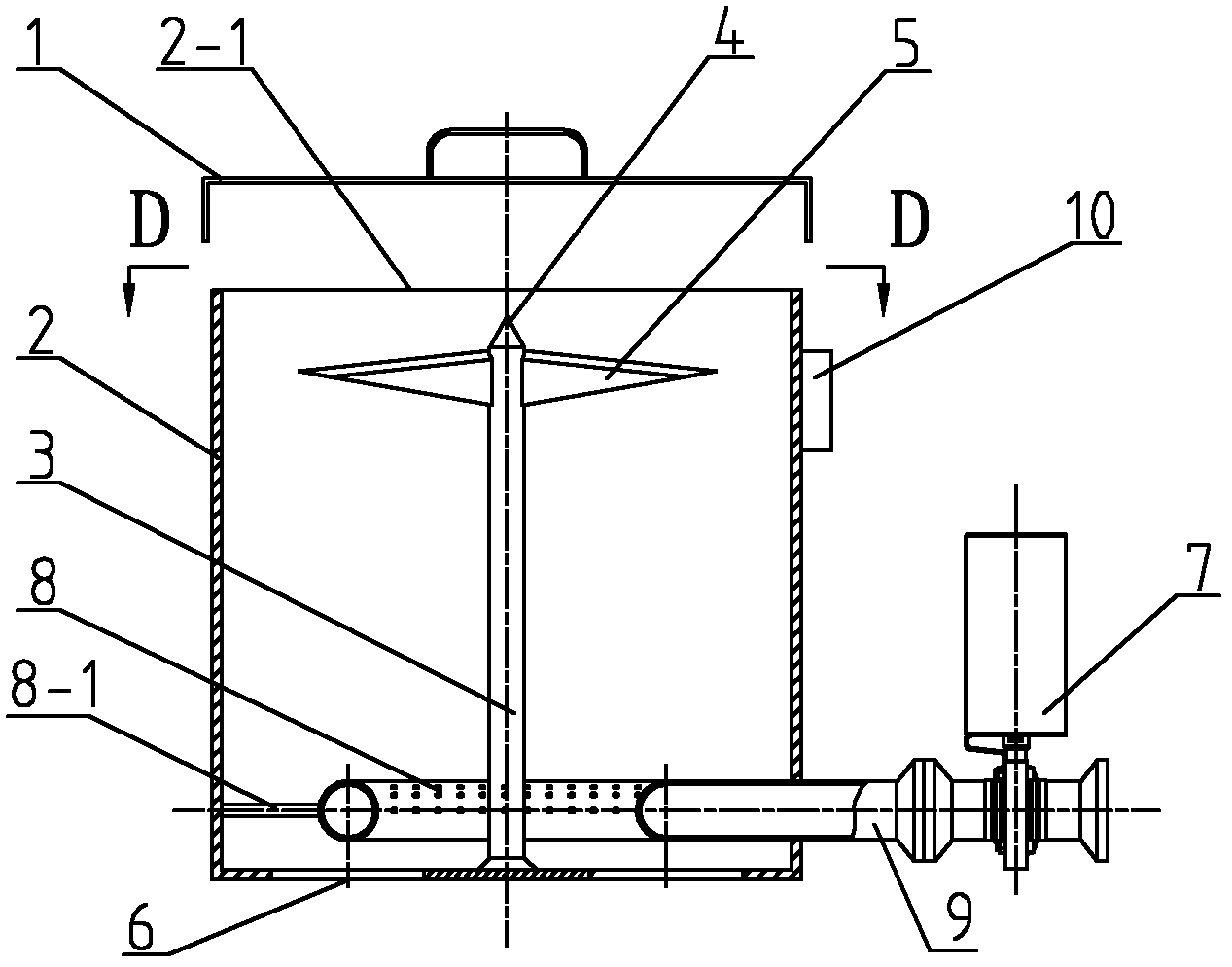

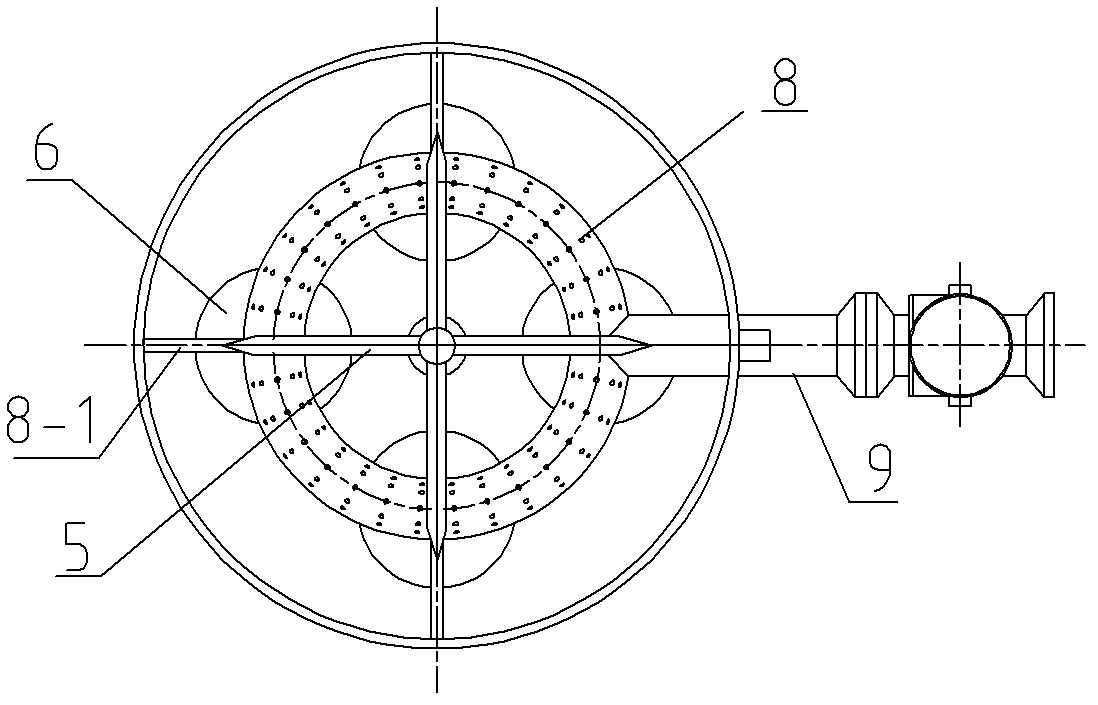

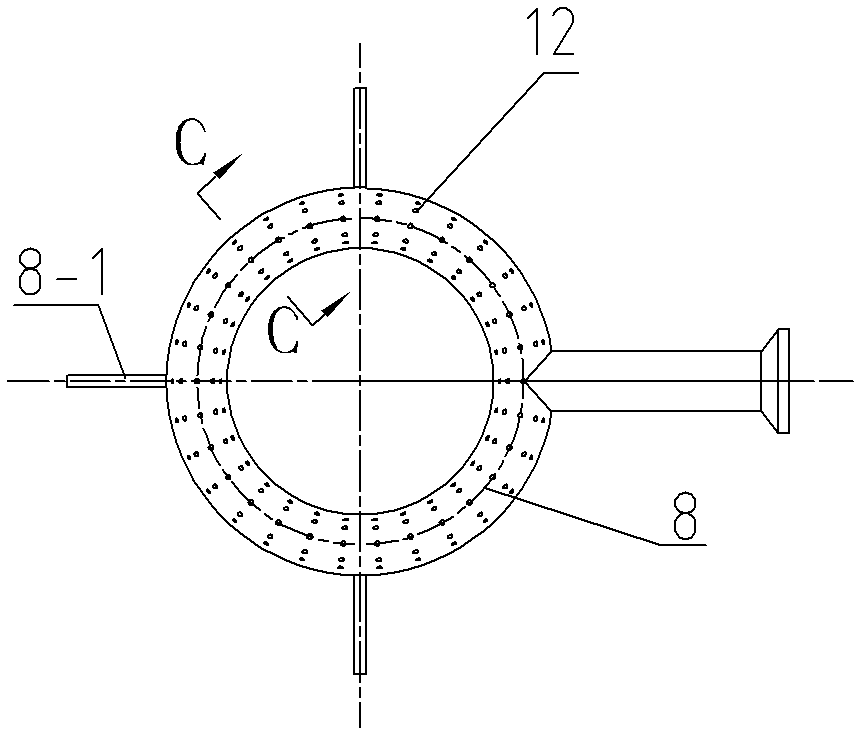

[0033] Such as figure 1 As shown, the sliced space bag inflatable automatic bag cutting device includes a revolving shell shape with an upper end open (in addition to the revolving shell shape, the receiving cylinder can also be made into an elliptical or polygonal shape) and a receiving cylinder 2 installed in the receiving cylinder. The lid 1 on the top of the barrel (for the clarity of the drawing, figure 1 The middle cover has been lifted up some distances), and the bottom of the receiving bin is attached to the top of the receiving bin 11 (the receiving bin cover is placed on the feeding port at the top of the receiving bin).

[0034] In this device: the central knife rod 3 is installed in the center of the material receiving barrel, and the cone tip at the top of the central knife rod should be kept in a sharp conical shape to facilitate p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com