Dye transfer device and dye dissolution equipment

A transfer device and dye technology, applied in transportation and packaging, textiles and papermaking, textile material processing, etc., can solve pollution, time-consuming, labor-consuming and other problems, and achieve the effects of avoiding pollution, convenient operation, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention are described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

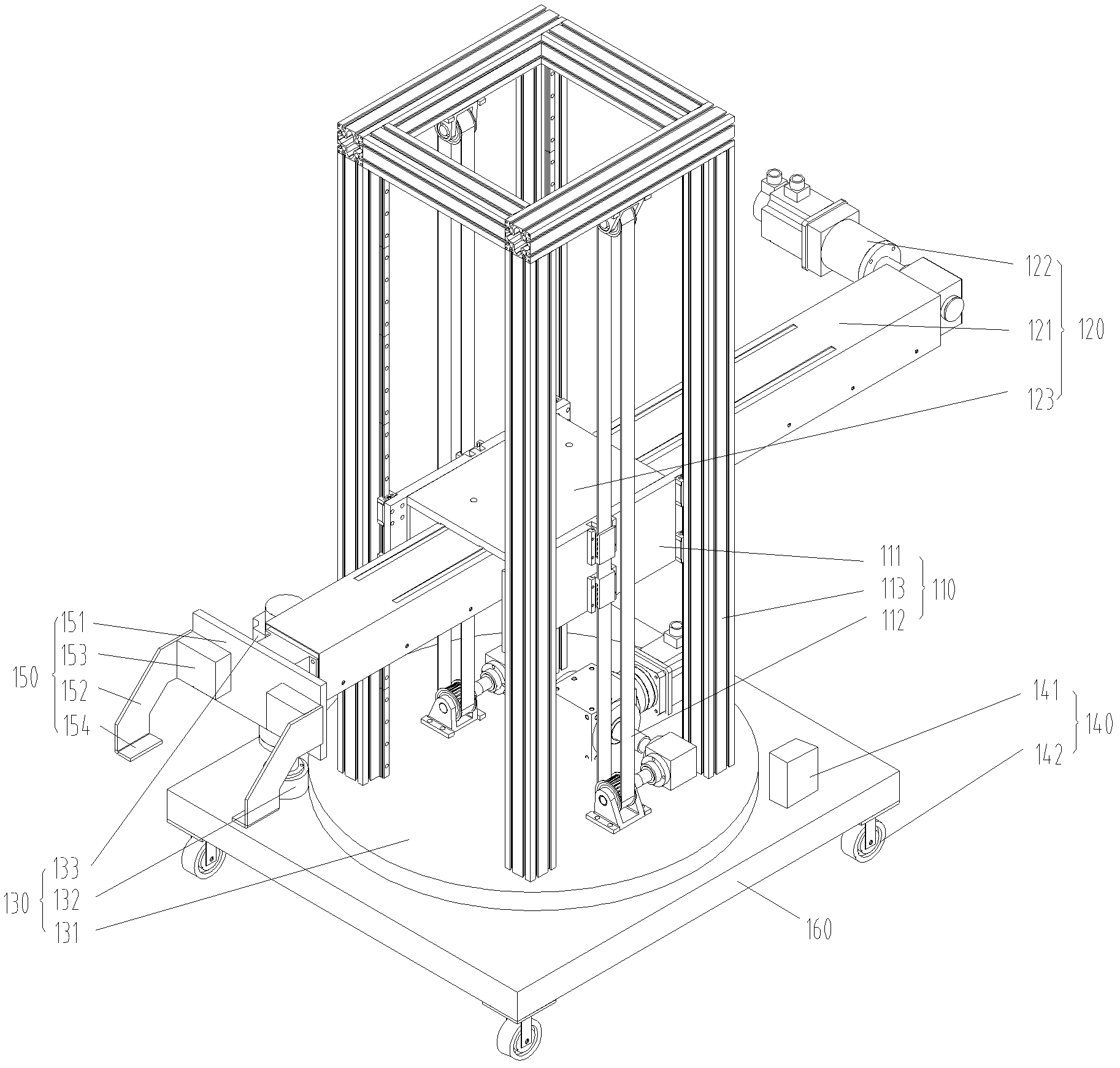

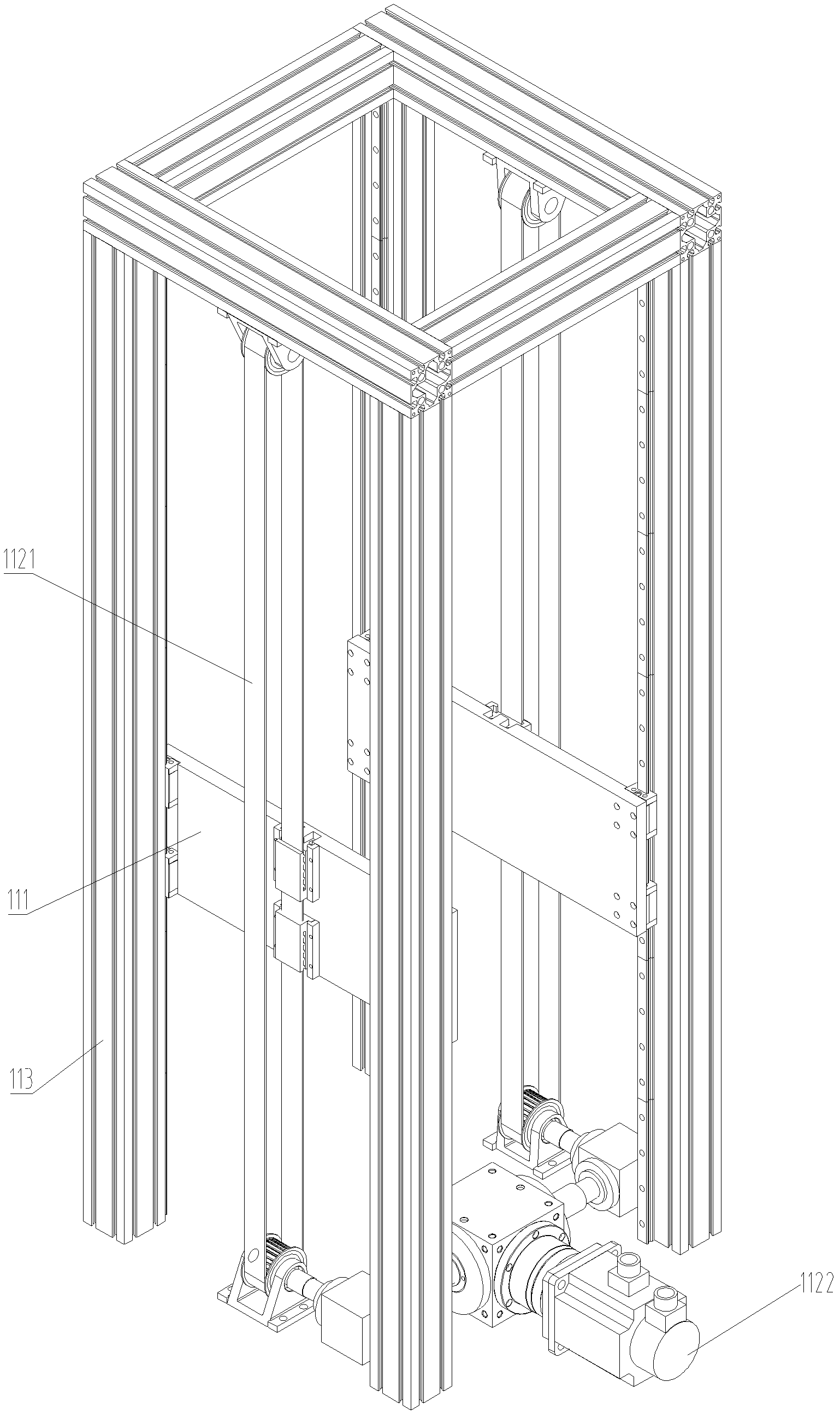

[0028] As a first aspect of the present invention, a dye transport device is provided. like figure 1 and figure 2 As shown, the dye transfer device includes: a base 160, a manipulator 150, a position adjustment unit and a control unit (not shown).

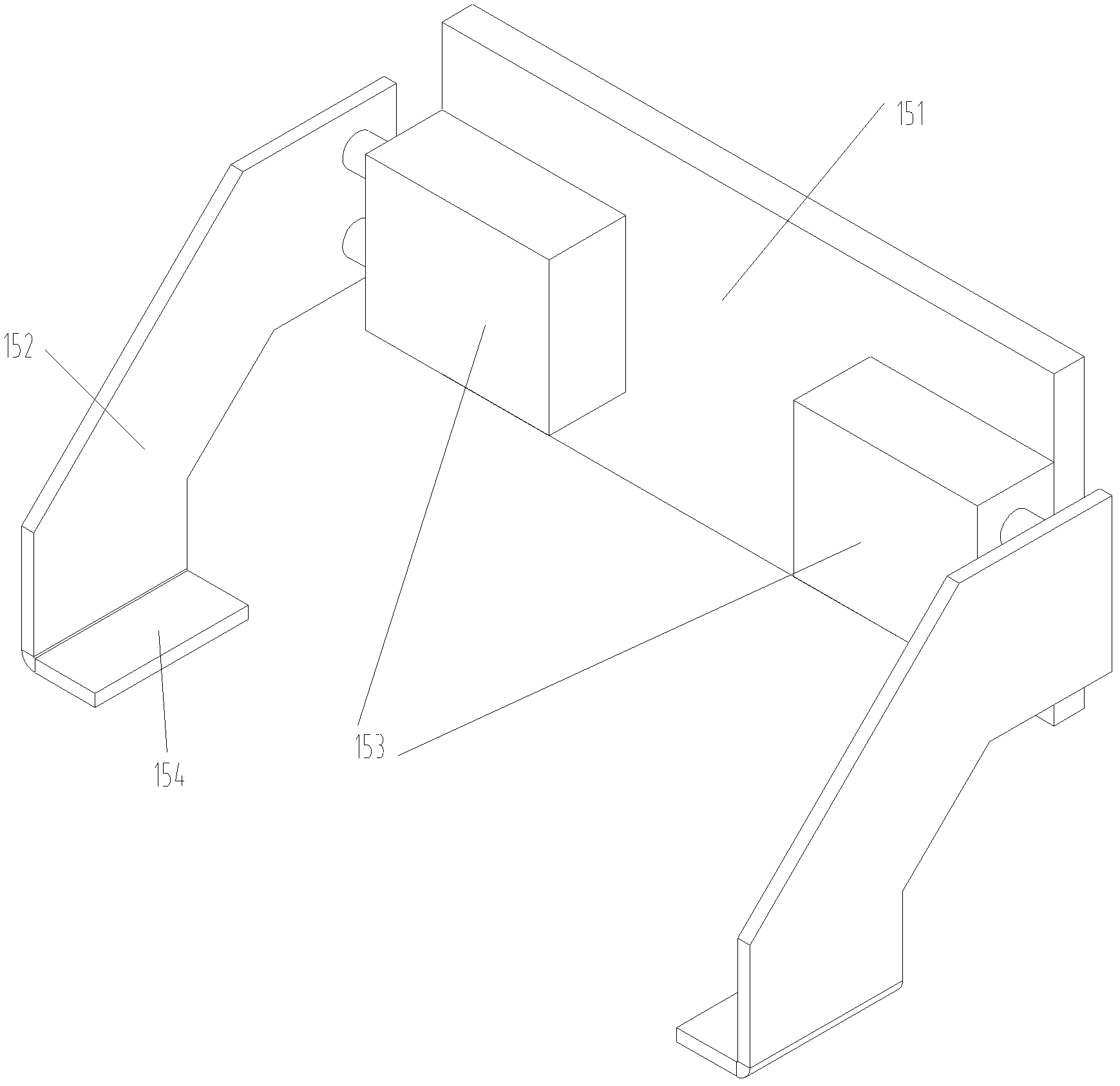

[0029] The manipulator 150 includes a clamping part and a driving part 153 for driving the clamping part. The position adjusting unit is disposed on the base 160 , and the position adjusting unit drives the manipulator 150 to move. The control unit controls the position adjustment unit to move the manipulator 150 to the target position, and controls the manipulator 150 to perform grasping and releasing actions. The control unit may be a microprocessor or a PLC controller or the like.

[0030] The ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com