Processing device and processing method of nitrogen pollutant in secondary tail water of sewage treatment plant

A sewage treatment plant and treatment device technology, applied in the direction of water/sewage multi-stage treatment, illuminated water/sewage treatment, oxidized water/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

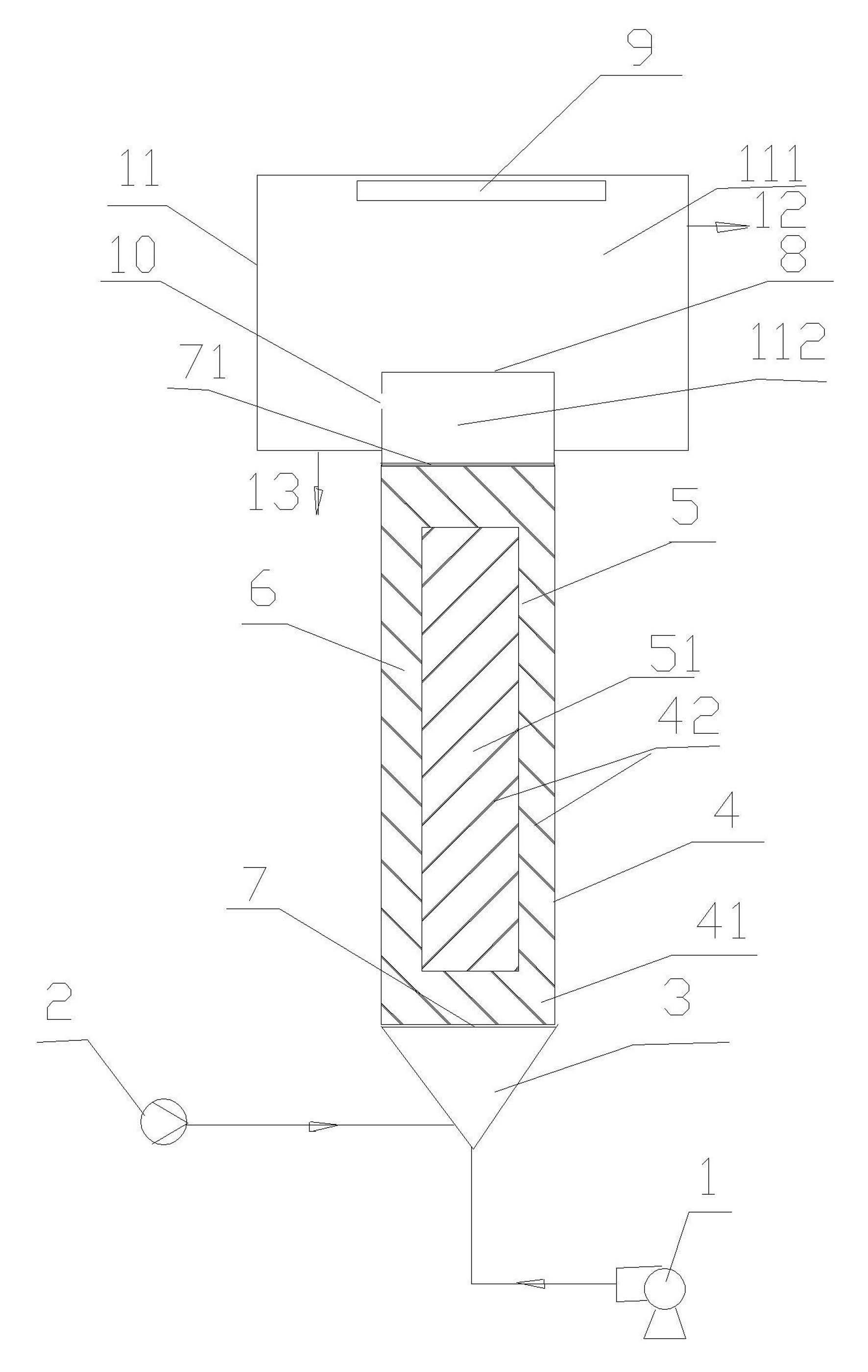

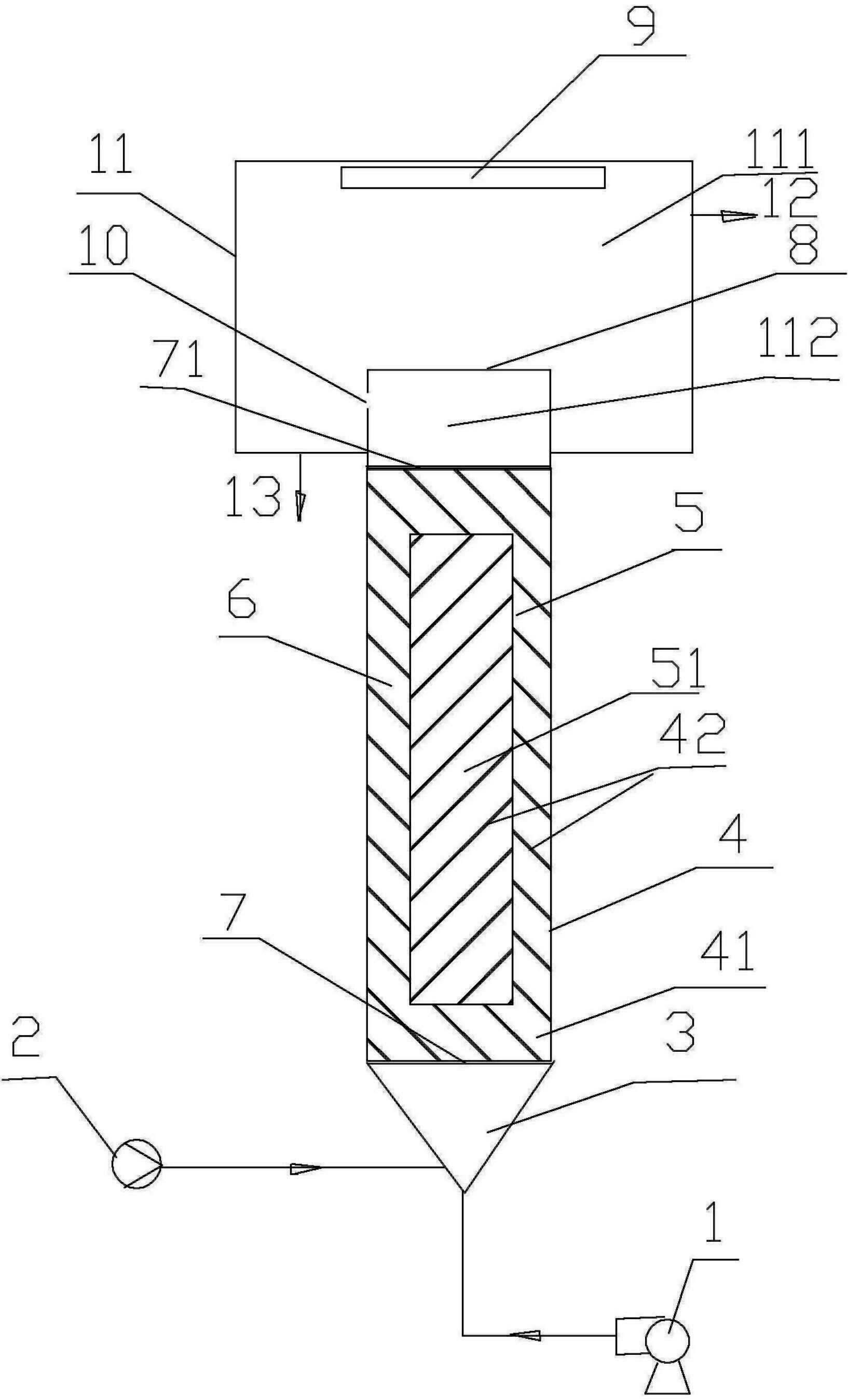

[0018] The structure and usage method of the device are described in conjunction with the accompanying drawings.

[0019] Such as figure 1As shown, the treatment device for nitrogen pollutants in the secondary tail water of the sewage treatment plant includes a treatment device housing 4, and an upper partition 71 with a mesh and a lower partition are respectively installed on the upper and lower parts of the treatment device housing 4 7. The upper and lower partitions are stainless steel mesh plates, which are mainly used to fix bamboo wire filler. The lower partition 7 divides the inside of the processing device housing 4 into the gas-water mixing zone 3 below the lower partition 7 and the main reaction zone 41 above the lower partition 7, in which a draft tube 5 is installed The main reaction zone is divided into an air-water upflow zone 51 inside the guide tube and a downflow zone 6 outside the tube; this embodiment is a cylinder or a square tube or a polygonal tube. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com