Technology for removing organic matters in reverse osmosis concentrated water

A technology for reverse osmosis concentrated water and organic matter, which is applied in the fields of water pollutants, water/sewage treatment, water/sewage multi-stage treatment, etc. The effect of strong operability, simple equipment and good market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

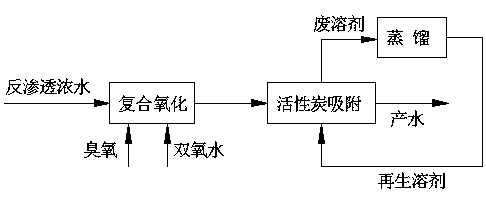

Image

Examples

Embodiment 1

[0029] The COD of reverse osmosis concentrated water in a coking plant is 170mg / L. The wastewater first enters the composite oxidation tower, the hydraulic retention time is 0.5h, the dosage of ozone is 200mg / L, and the dosage of hydrogen peroxide is 200mg / L. Wastewater COD is reduced to 100mg / L, the effluent enters the activated carbon adsorption tower, the amount of activated carbon filled in the adsorption tower is 10% of the influent, the residence time of the adsorption tower is 30min, the COD of the effluent of the adsorption tower is reduced to 50mg / L, and the activated carbon in the adsorption tower is regenerated The regeneration solvent used is methanol, the regeneration time is 60 minutes, and the activated carbon can be recycled for more than 30 times.

Embodiment 2

[0031] The COD of reverse osmosis concentrated water in a coal chemical plant is 230mg / L. The wastewater first enters the composite oxidation tower, the hydraulic retention time is 1.5h, the dosage of ozone is 350mg / L, and the dosage of hydrogen peroxide is 400mg / L. After composite oxidation Wastewater COD is reduced to 120mg / L, the effluent enters the activated carbon adsorption tower, the amount of activated carbon filled in the adsorption tower is 15% of the influent, the residence time of the adsorption tower is 60min, the COD of the effluent of the adsorption tower is reduced to 60mg / L, and the activated carbon in the adsorption tower is regenerated The regeneration solvent used is ethanol, the regeneration time is 90 minutes, and the activated carbon can be recycled for more than 30 times.

Embodiment 3

[0033] The COD of reverse osmosis concentrated water in a paper mill is 280mg / L. The wastewater first enters the composite oxidation tower, the hydraulic retention time is 2.5h, the dosage of ozone is 500mg / L, and the dosage of hydrogen peroxide is 450mg / L. After composite oxidation Wastewater COD is reduced to 140mg / L, the effluent enters the activated carbon adsorption tower, the amount of activated carbon filled in the adsorption tower is 20% of the influent, the residence time of the adsorption tower is 90min, the COD of the effluent of the adsorption tower is reduced to 70mg / L, and the activated carbon in the adsorption tower is regenerated The regeneration solvent used is acetone, the regeneration time is 120min, and the activated carbon can be recycled more than 30 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com