High-strength and high-plastic retaining ability concrete plastic retaining agent and application method of plastic retaining agent

A plastic concrete and plastic retaining agent technology, applied in the field of concrete admixture, can solve the problems that affect the popularization and application of high-strength concrete, there is a big gap, and the slump loss is large, so as to delay the slump loss, delay the formation, The effect of improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

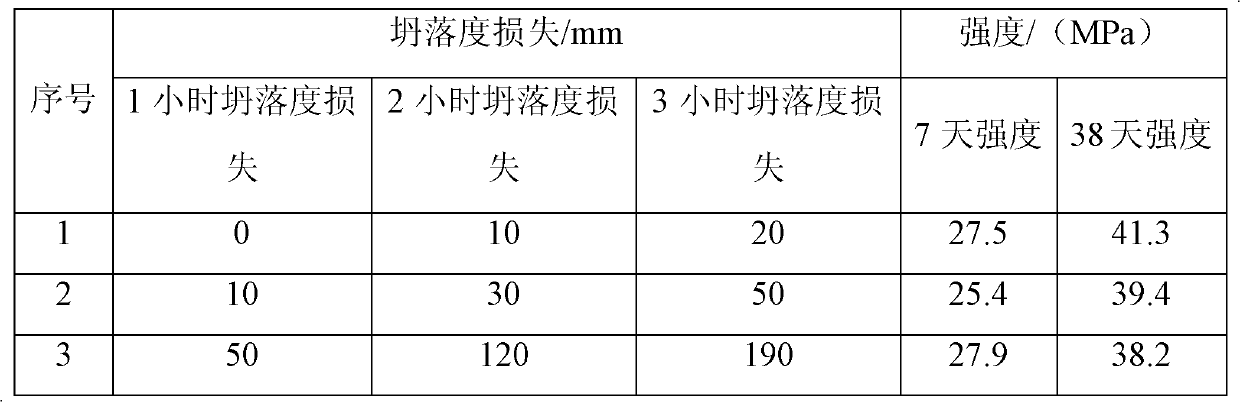

[0021] First mix 1 part (parts by weight, the same below) of boric acid and 14 parts of lactone, stir well to obtain the mixture, then add 8 parts of honey, 28 parts of rock sugar, 2 parts of ethyl acetate, and 2 parts of ferrous sulfate to the above-mentioned In the mixture, finally add 45 parts of water to mix, and after stirring evenly, a high-strength and high-retaining plastic plastic retaining agent for concrete is obtained, and the prepared admixture (serial number 1) and ordinary plastic retaining agent (serial number 2) are added according to 0.05% of the quality of the concrete adhesive Into the concrete mixture, and carry out comparative experiment with the concrete (serial number 3) that does not mix plastic retaining agent, experimental result is as table 1:

[0022] Table 1

[0023]

[0024] As can be seen from Table 1, the concrete slump loss of the product of this embodiment is very small, while the concrete with common plastic retaining agent and the concre...

Embodiment 2

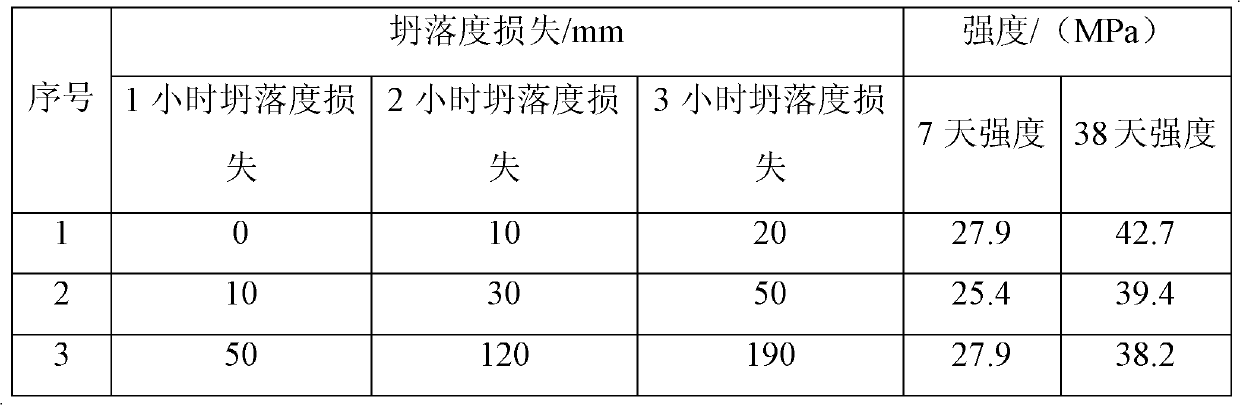

[0026] First mix 3 parts of boric acid and 10 parts of lactone, stir well to get the mixture, then add 10 parts of honey, 20 parts of rock sugar, 3 parts of ethyl acetate and 2 parts of ferrous sulfate to the above mixture in turn, and finally add 52 parts Mix with water, stir evenly to prepare high-strength and high-retaining plastic plastic retaining agent for concrete, add the prepared admixture (serial number 1) and common plastic retainer (serial number 2) to the concrete mixture by 0.05% of the quality of the concrete adhesive, And carry out contrastive experiment with the concrete (serial number 3) that does not mix plastic retaining agent, experimental result is shown in Table 2:

[0027] Table 2

[0028]

[0029] As can be seen from Table 2, the concrete slump of the product of this embodiment has no loss substantially, while the concrete with ordinary plastic retaining agent and the concrete without plastic retainer have a slump of 10 mm and 50 mm in 1 hour, so T...

Embodiment 3

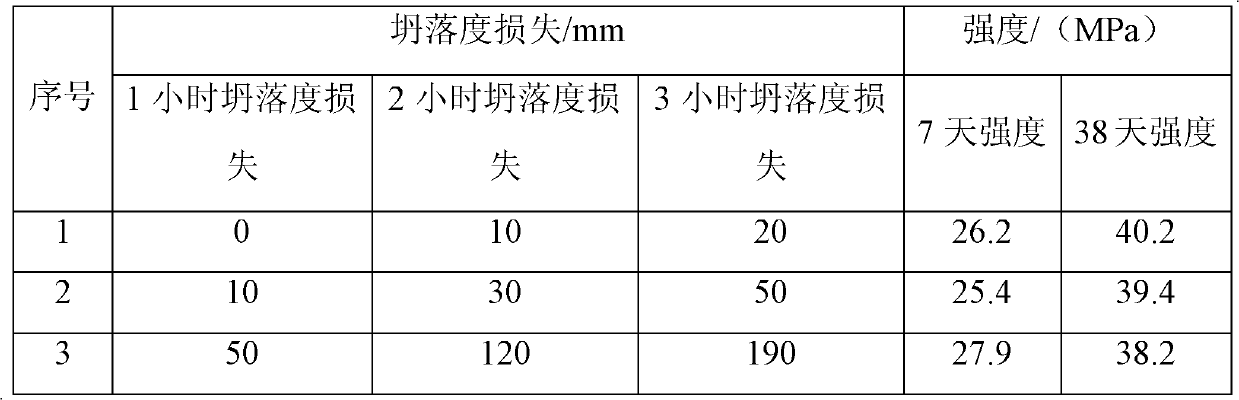

[0031] First mix 5 parts of boric acid and 7 parts of lactone, stir well to get the mixture, then add 14 parts of honey, 12 parts of rock sugar, 6 parts of ethyl acetate and 6 parts of ferrous sulfate to the above mixture in turn, and finally add 50 parts of mixed with water, and stirred evenly to prepare a high-strength and high-retaining plastic plastic retaining agent for concrete, the prepared admixture (No. 1) and common plastic retaining agent (No. 2) were added to the concrete mixture by 0.05% of the quality of the concrete adhesive , and compared with the concrete (No. 3) without plastic retaining agent, the experimental results are shown in Table 3:

[0032] table 3

[0033]

[0034] As can be seen from Table 3, the concrete slump loss of the product of this embodiment is very small, while the concrete with ordinary plastic retaining agent and the concrete without plastic retainer have a slump of 10 mm and 50 mm in 1 hour, so The plastic retaining agent of the pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com