Preparation method of unsaturated polyester resin for button

A polyester resin and unsaturated technology, applied in the field of unsaturated polyester resin for buttons and its preparation, can solve the problems of restricting the use of plasticizers, easily absorbing water, and turning white

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

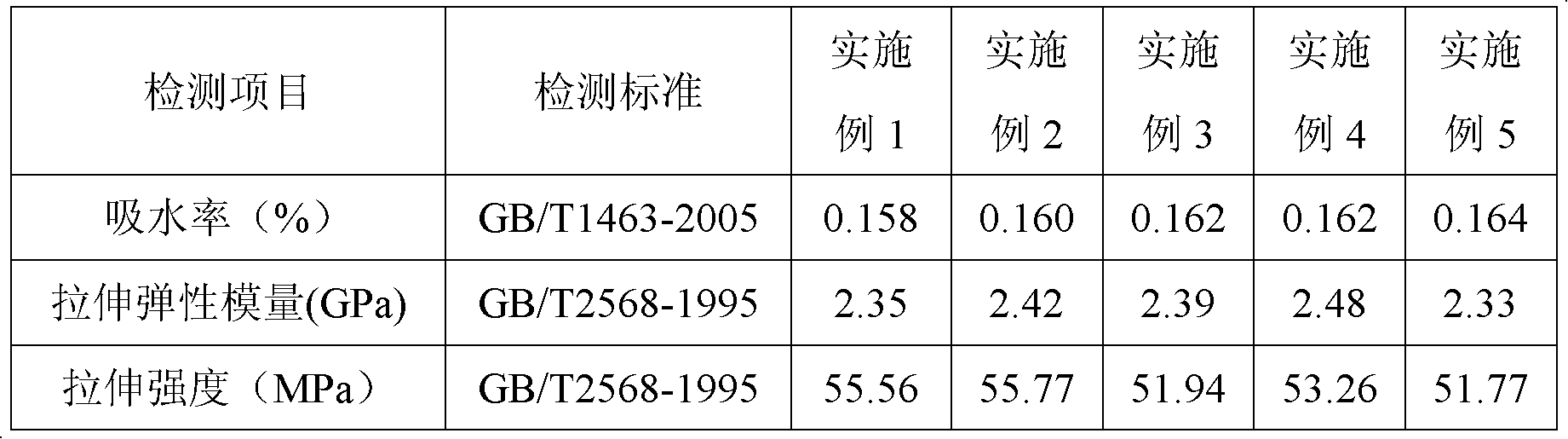

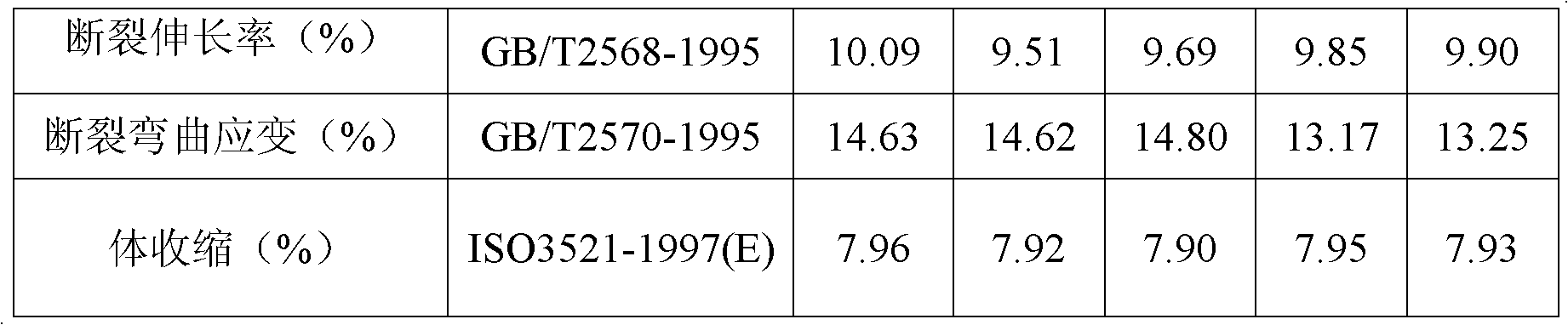

Examples

Embodiment 1

[0032] Formula: 2600 parts by weight of phthalic anhydride, 1100 parts by weight of maleic anhydride, 800 parts by weight of 1,2-propanediol, 600 parts by weight of ethylene glycol, 1200 parts by weight of diethylene glycol, 2700 parts by weight of styrene, and 0.5 parts by weight of hydroquinone , 0.7 parts by weight of methyl hydroquinone, 2 parts by weight of triphenyl phosphite, 0.05 parts by weight of copper naphthenate, 2 parts by weight of paraffin, 0.05 parts by weight of toner, and 0.015 parts by weight of fluorescent whitening agent.

[0033] The preparation method of unsaturated polyester resin for this button is:

[0034] a) After mixing phthalic anhydride, maleic anhydride, 1,2-propanediol, ethylene glycol, diethylene glycol, high-temperature polymerization inhibitors, and antioxidants, the temperature is raised to effluent in 1-2 hours, and then heated at 8-10°C / h Speed up to 210°C, keep warm for 5 hours, the acid value of the material reaches 68mgKOH / g, vacuum...

Embodiment 2

[0038] Formula: 2500 parts by weight of phthalic anhydride, 1200 parts by weight of maleic anhydride, 900 parts by weight of 1,2-propanediol, 700 parts by weight of ethylene glycol, 1300 parts by weight of diethylene glycol, 2600 parts by weight of styrene, and 0.6 parts by weight of hydroquinone , 0.9 parts by weight of methyl hydroquinone, 2.5 parts by weight of triphenyl phosphite, 0.04 parts by weight of copper naphthenate, 2.5 parts by weight of paraffin;

[0039] The preparation method of unsaturated polyester resin for this button is:

[0040]a) After mixing phthalic anhydride, maleic anhydride, 1,2-propanediol, ethylene glycol, diethylene glycol, high-temperature polymerization inhibitors, and antioxidants, the temperature is raised to effluent within 1-2 hours, and then heated at 8-10°C / h Raise the temperature to 215°C at a certain speed, keep it warm for 4 hours, the acid value of the material reaches 72mgKOH / g, vacuumize and reduce the pressure, the vacuum degree re...

Embodiment 3

[0044] Formula: 2700 parts by weight of phthalic anhydride, 1000 parts by weight of maleic anhydride, 700 parts by weight of 1,2-propanediol, 500 parts by weight of ethylene glycol, 1100 parts by weight of diethylene glycol, 2800 parts by weight of styrene, and 0.4 parts by weight of hydroquinone , 0.7 parts by weight of methyl hydroquinone, 1.5 parts by weight of triphenyl phosphite, 0.06 parts by weight of copper naphthenate, 1.5 parts by weight of paraffin;

[0045] The preparation method of unsaturated polyester resin for this button is:

[0046] a) After mixing phthalic anhydride, maleic anhydride, 1,2-propanediol, ethylene glycol, diethylene glycol, high-temperature polymerization inhibitors, and antioxidants, the temperature is raised to effluent within 1-2 hours, and then heated at 8-10°C / h Raise the temperature to 210°C at a certain speed, keep it warm for 4 hours, the acid value of the material reaches 70mgKOH / g, vacuumize and reduce the pressure, the vacuum degree r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com