Method for preparing polyether polyol

A technology of polyether polyol and polymerization reaction, which is applied in the field of polyol preparation, can solve the problems of difficult reaction unit and curing unit, and achieve the effects of beneficial polymerization reaction, elimination of gas phase dead zone, and narrow molecular weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

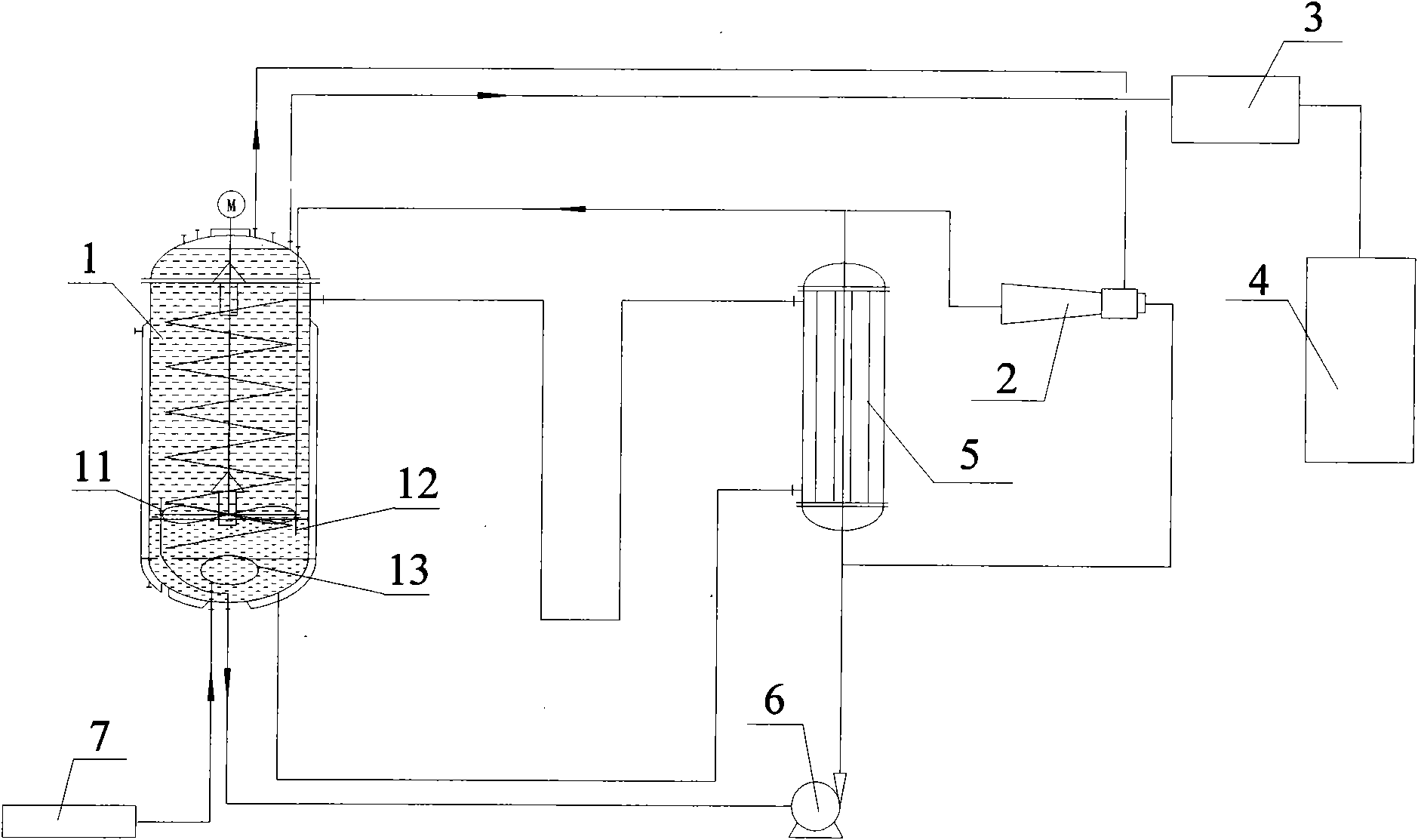

[0023] A kind of method for preparing polyether polyol, its process flow diagram is as figure 1As shown, the method comprises the following steps: After mixing double metal cyanide complex catalyst, oxyalkylene and polyether polyol with molecular weight of 200 as starter in static mixing reactor 7, from the bottom of main reactor 1 Imported into the main reactor 1, the reaction temperature is controlled at 140-150°C, and the reaction time is 0.5h. Polymerization occurs through mass transfer and heat transfer. In the main reactor, through mass transfer and heat transfer, although most of the reactants are in the liquid The polymerization reaction has been carried out in the phase, but there is still unavoidably a small part of unreacted oxyalkylene monomers gathered at the top of the main reactor 1, and this part of unreacted oxyalkylene monomers enters the secondary reactor 2 of the circulating reaction system, The reaction temperature is controlled at 140-150°C, and the react...

Embodiment 2

[0028] A kind of method for preparing polyether polyol, its technological process is identical with embodiment 1, and the raw material that adopts is that double metal cyanide complex catalyst, oxyalkylene and molecular weight are 600 polyether polyols as initiator, main reactor The reaction temperature is , the reaction pressure is , the reaction temperature of the secondary reactor is , the reaction pressure is , the reaction temperature of the aging tank is , and the reaction pressure is . The obtained polyether polyol has an average functionality of 2; the molecular weight of the polyether polyol is 50000; and the degree of unsaturation is 0.002.

Embodiment 3

[0030] A kind of method for preparing polyether polyol, its technological process is identical with embodiment 1, the raw material that adopts is that double metal cyanide complex catalyst, oxyalkylene and molecular weight are the polyether polyol of 1000 as initiator, main reactor The reaction temperature is , the reaction pressure is , the reaction temperature of the secondary reactor is , the reaction pressure is , the reaction temperature of the aging tank is , and the reaction pressure is . The obtained polyether polyol has an average functionality of 8, the molecular weight of the polyether polyol is 10000, and the degree of unsaturation is 0.010.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

| degree of unsaturation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com