Silt removing machine for sewage-discharging channels

A technology of dredging device and walking mechanism, which is applied in the direction of earth mover/excavator, construction, etc. It can solve the problems of high labor intensity, threat to workers' personal safety, and bad conditions, so as to reduce labor intensity, achieve good dredging effect, The effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

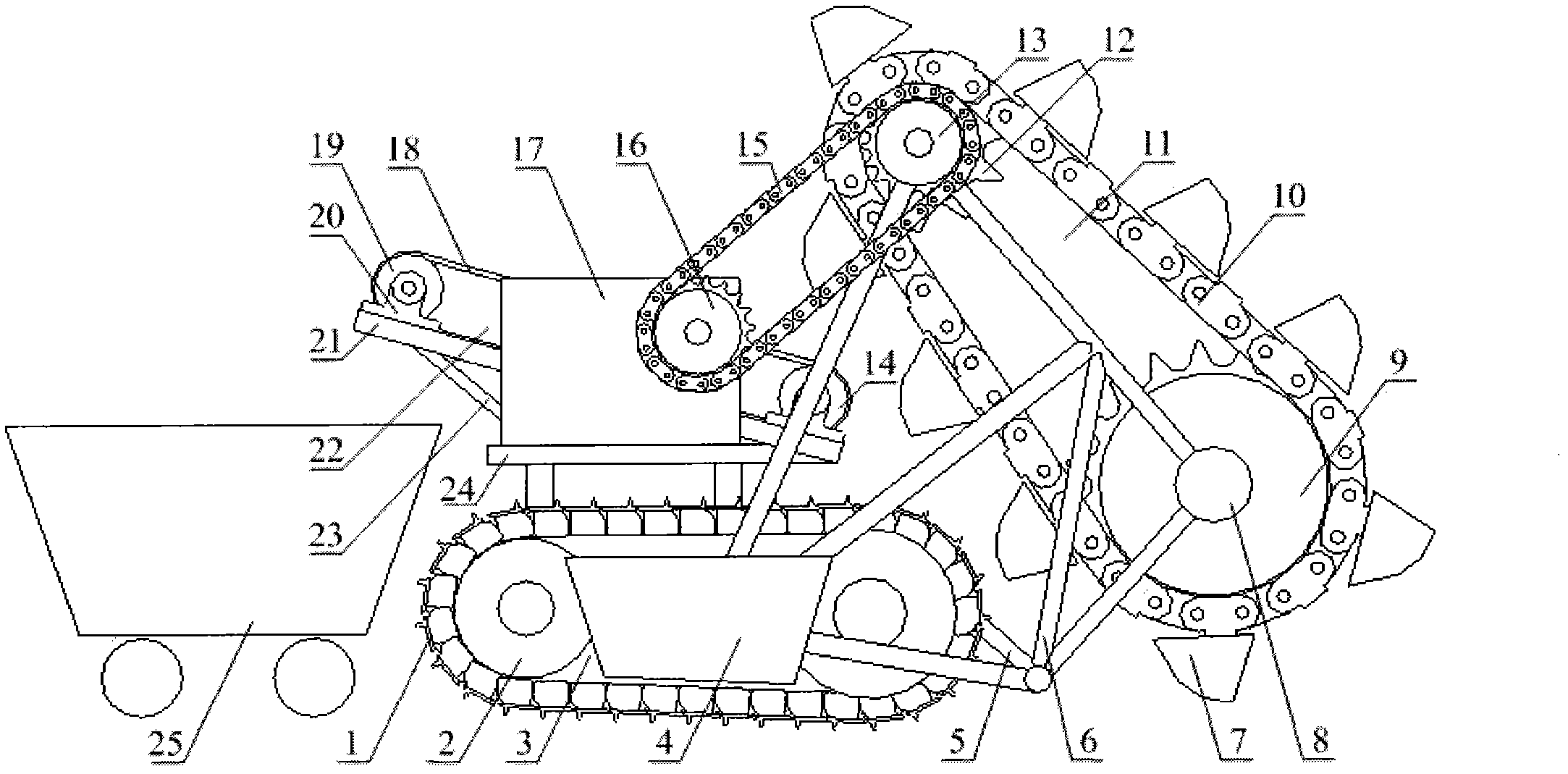

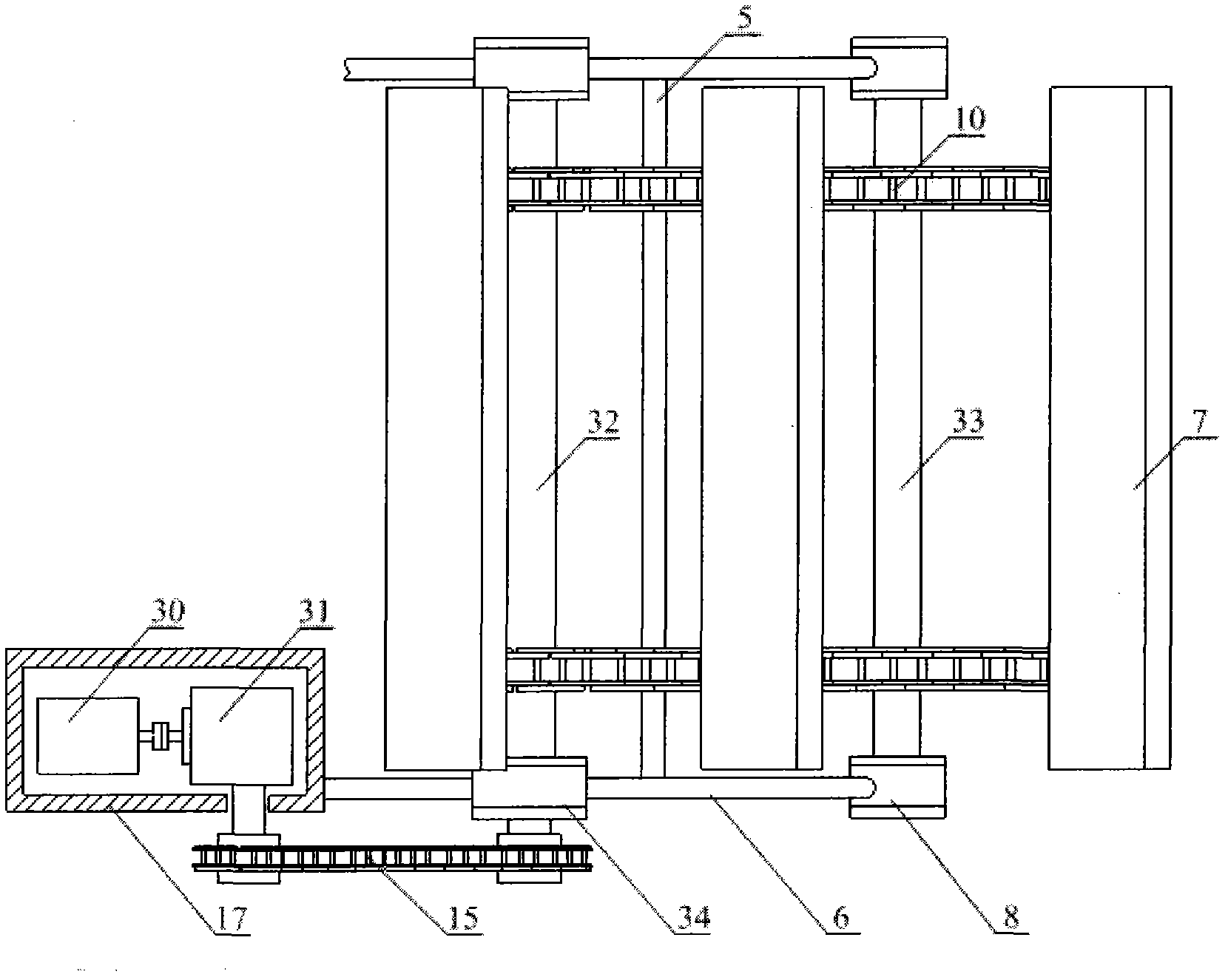

[0011] See attached figure 1 , the present embodiment sewage ditch dredging device comprises: traveling mechanism 3, excavating mechanism 11, conveying mechanism 22, and the connection mode of whole device is: traveling mechanism 3 is the support of whole device, and support plate 24 is fixed on its chassis; Excavation The mechanism 11 is arranged obliquely in front of the traveling mechanism 3, connected with the traveling mechanism 3 by the bracket 6, and associated with the excavating power box 17 arranged on the support plate 24 through the driving chain 15; the conveying mechanism 22 is arranged above the traveling mechanism 3 And the rear bottom of the excavating mechanism 11 is obliquely arranged on the support plate 24 by the support rod 23 .

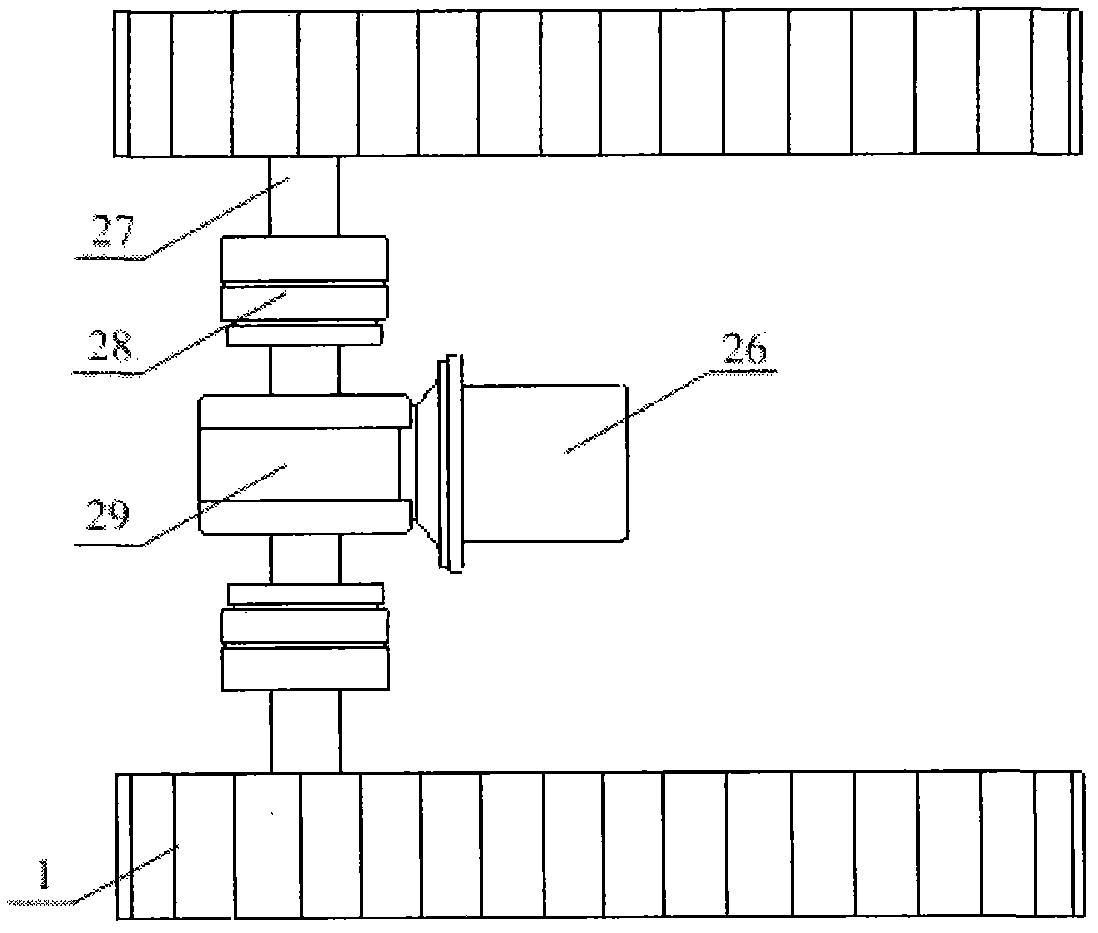

[0012] See attached figure 1 And attached figure 2 , the running gear 3 of the present em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com